Going back to the past to survive

- Published

When these ladies were inspecting lace in 1959 there were about 100 factories making Nottingham lace

Nottingham was once world famous for lacemaking.

"It's a very healthy industry," a factory boss told the BBC's Richard Dimbleby in 1951 - as 120 firms still churned out intricate designs for the world's dresses, lingerie and tablecloths.

But a few decades earlier, there had been 200 firms. Times were changing - though too few had noticed.

In 1979, an ATV reporter interviewed a spokesman for the Guy Birkin Ltd factory: "I would have thought you would have great competition from countries like Japan and Taiwan etc?"

And the reply?

"These people couldn't set up an industry just like that. We, in fact, in this country have a monopoly."

But "those people" did, and now the UK doesn't have a lacemaking industry.

Susan Twigg now works for the last firm of its kind in the region

Clinging on

Today, the unique rhythm of the old Leavers machines can be heard in just a few places in the world, the centuries-old family firm of Cluny Lace being one of them.

"All the big old factories, they were full of lace machines in the 40s and 50s - there's none now," says Peter Sewell, one of the last few lace twist hands still practising their craft.

"We've been making lace for up to nine generations," says Charles Mason, who inherited Cluny, almost the last working factory still making Nottingham lace.

"We can trace our roots back to the stocking frame manufacturing days. Of the styles that we specialise in, we've been the last ones left for maybe 15 years."

Somehow Cluny and its staff, based in Ilkeston, Derbyshire, are clinging on - partly because they don't rely on bank loans. But also because they've taken an enormous gamble.

Cluny sold off its modern Raschel machines - the huge, computer-driven automatons which now make mass-produced lace a relatively cheap product across the world.

And decided to rely on its old, 19th-Century Leavers machines, which make lace of an intricacy that is hard to copy.

Cluny's old machines can make complex patterns in demand from high-fashion houses

"We had a large plant of modern Raschel machinery," says Sheila Mason.

"Absolutely fantastic for high-speed production, but we couldn't compete on price. It was a very great risk, but we had no option. If we had kept that Raschel plant, I don't think the Leavers would have been here today."

Selling their Raschel machines lost Cluny 80% of their business.

High fashion demand

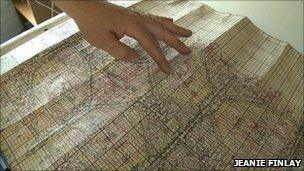

Instead, Cluny has relied entirely on the century-old Leavers machines with their beautiful Jacquard cards, intricate patterns and clanking metal arms.

"No-one has the style of patterns we do," says Charles Mason. "[They're] the closest you can get to handmade lace that's made by a machine."

The result: they still have a market among fashion designers.

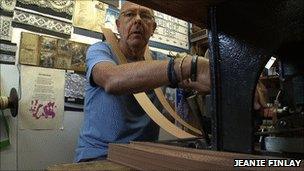

Ian Emm, believed to be the UK's last Jacquard card puncher, says young people don't want factory work

A recent Marie Claire cover shows a design using Cluny Lace. "The main buyers are the haute couture houses - Dolce & Gabbana in Italy, for example, Etro in Italy, Christian Dior in France. In the UK, for example, Paul Smith has been a valued customer for a long time. Vivienne Westwood is another."

"I think the designers themselves know who we are," Charles Mason says, "and that's the important thing."

But the public doesn't know the lace is unique, so there is little public demand for it by name. "The person in the street," twist hand Ian Palfreyman says, "doesn't really understand fully what the quality is. They look at a garment and they'll see it's lace, but I don't think they understand the quality of the lace.

They don't understand the difference between a Leavers pattern and a Raschel pattern."

Running out

Lace factories used to have rooms full of women menders and winders. In Cluny now there's one mender, stitching any flaws, and a couple of winders preparing the lace for customers.

And the men who operate the machines are on the edge of retirement.

"The fabric is actually twisted, not knitted," says Ian Palfreyman.

"That's why we're called twist hands. A twist hand's job is to keep a machine running with a high quality, making high-quality lace."

"Each machine is different. They've all got their own little quirks, so it's a lot to remember to keep going round all these machines and try and remember - oh yeah, this one works with that machine but it doesn't work with that machine."

"Twist Hands Only" signs once hung on backrooms in local pubs - only these bowler-batted aristocrats of labour allowed inside.

"That's the top of the tree - the twist hand. If you haven't got your twist hand, you haven't got a business. The twist hand will make it, then it goes to a mender who will mend it if it needs to be mended."

Young uninterested

"Unfortunately," says Charles Mason, "I would say three-quarters of the people here will be retiring in five years. Those people are approaching 60 - or over 60 now.

The skills to operate the machinery are disappearing

"Traditionally, I was always told it took seven years of apprenticeship to be able to work [to get to know] the different styles of patterns and the different gauges. It's a huge potential problem on the horizon."

"What do young people want to come into this trade for, especially at the manufacturing end - because it's so dirty, you know," says Ian Emm.

He believes he is the UK's last Jacquard card puncher. The elaborate holes he creates in the cards form the designs made by the machines.

"Younger people coming into a trade want a guarantee of a career out of it," he says "and this is so uncertain."

"Unfortunately, says Cluny director Sheila Mason, "most of them seem to think that there's probably more future in sweeping the floor at a supermarket than there probably is in the textile trade."

There's no doubt the odds aren't great. Parts are hard to come by, as are people to repair the machines. And Sheila says there is only one lace dye works in the whole of Western Europe.

Across the developing world, family firms are advised to cling onto niche markets, in today's globalised world - and exploit unique craft skills.

Cluny has yet to prove that the advice works in the post-industrial world, but they are definitely trying. "[Cluny] is the only company left in the UK that makes Leaver's lace - the best lace," says Ian Emm.

"Quality should rise above and I'd hope - I'd always hope - the stuff they make here, which is quality, will keep its head above water."

"I hope there is a future," says Charles Mason, "I'm sure there is. There is still without question a market for high-quality lace items of the style we do - as long as we've got the supply chain somewhere, which we should have to keep us going."

For now, the machines clang on.

Life on the Edge is broadcast on BBC World News on Saturday at 0030, 0730 and 1930 GMT, and on Sunday at 1330 GMT.