Individuality drive and 3D tech make firms go bespoke

- Published

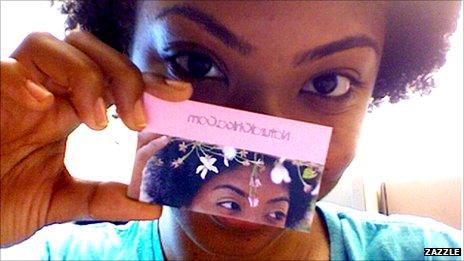

At Zazzle, users can choose among many different designs to customise their products - and they can upload their designs, too

We all want to be unique.

Hairstyle like no-one else's in your office, a handmade tie bought in a tiny Parisian boutique, a diamond wedding ring from that exclusive collection.

This global individuality drive combined with the latest technologies has been stimulating companies to produce what used to be off-limits just a while back - mass-oriented bespoke content.

Now websites of firms like Converse, Nike and Keds, for instance, offer the chance to create customised training shoes with just a few mouse clicks - and they cost little more than those from the regular in-store collection.

One click - and the trainer changes from blue to bright yellow; one more - and the laces become green.

As the mouse cursor trots across the screen, you can even change the interior lining and add a cool personalised signature.

So when the shoes get delivered to your doorstep, they will be like no other pair.

Another example is Zazzle, external - a US online shop that lets you customise products ranging from stylish iPhone cases to T-shirts and skateboards.

"One of the most powerful trends in consumerism is toward individualism - consumers don't want to be spoon-fed the same media, entertainment or products," says the company's co-founder, Jeff Beaver.

Not Just A Label website brings designers and shoppers together

"They want to create their own, publish it to the world and leverage new technologies and services to self-express."

Besides choosing from tens of millions of designs and billions of actual product combinations, Zazzle users from around the globe can even upload their own ideas and sell them right there and then.

This way, some 150,000 new products are designed and published every single day, says Mr Beaver.

"The biggest challenge in enabling an effective online customisation experience is that the products don't actually exist yet," he adds.

"That is, we must preview to the user what a product would look like, if it were to be manufactured."

To do that, the firm uses special visualisation technologies, employing techniques similar to those in the film industry to instantaneously render products in three-dimensional space - while also employing computational photography to enable texture mapping for images and designs on the surface of the product.

Bits and atoms

Customisation is nothing new - for ages, people have been able to order on-demand clothes.

But they have often been limited to expensive tailored suits and evening gowns, targeting a select few.

Mass production was totally different.

"If you look at 10 years ago, many firms had a very one-directional approach, the brand was everything - and it told consumers what they would consume," says Jonathan Chippindale from a UK software developer Holition, external.

"The brand created a look, consumers could buy the look and there wasn't really any variation on it, the look was king."

But the web and ever-evolving technologies changed that, and companies like Holition went even further than simple online customisation techniques.

In a bid to bridge the gap between bits and atoms, Holition created an augmented reality application that lets consumers visualise their newly "self-designed" product - be it a watch, a ring or a garment - directly on them, but in the virtual world.

For instance, on the website of a Swiss watchmaker Tissot, external, potential buyers launch the software, and and when they look into their webcam, they see themselves on the screen, but wearing a virtual watch.

They can then customise it by choosing different options available to them - a variety of bracelets, colours and other parameters - all while seeing the watch transform itself on their wrist.

Tissot president Francois Thiebaud says that the bespoke experience has allowed the company to sell a lot more watches.

"What makes it really special is the synergy of the touch technology of our Touch collection with the augmented reality functionality - it's the perfect way to get thousands of consumers to experience Tissot and experiment with its features," he adds.

Using an augmented reality software, shoppers are able to customise watches before they buy them

And even if shoppers cannot really design a watch from scratch, they still have a lot more choice than inside a store - so some uniqueness is guaranteed.

Authentic luxury

But once the demands are received, it is often tricky for the consumers to contact the manufacturer in case they change their minds about the chosen colour or material.

Not Just a Label, external deals with that problem - it serves as an online platform for direct interaction between designers and their clients.

When buyers visit the company's online shop and add a product to the cart, they are first asked to customise - to choose whether they want the ring, for instance, to be gold-plated or silver, bearing a shining diamond or a baby blue sapphire.

As they check out, another box pops up, and customers can add even more requests.

And once a designer starts working on such one-of-a-kind creation, the client can get in touch along the way to make comments and send additional measurements "to produce a truly personalised piece", says the company's co-founder Stefan Siegel.

"We call it authentic luxury. In today's world, money doesn't really distinguish you anymore - there are too many people with money.

"So the future of fashion is individuality - owning something unique and then keeping it for more seasons because it is so unique, and almost like having a story to tell your friends when you wear it."

3D printers

A tool that is proving incredibly useful in bespoke manufacturing of the 21st Century is 3D printing.

It has nothing to do with traditional paper printing.

Here, an object is made by stacking the material layer by layer to obtain what in the cross section would look like the French cake millefeuille, or baklava from a Middle Eastern bakery.

As designs first created online are fed into the printer's electronic brain, and the machine's other appropriate compartments are loaded with a necessary substance - plastic, metal or even chocolate - it is possible to obtain finished products that have never been screwed, stitched or glued together.

Now, there are companies that will print you a T-shirt, a mug, or a doorknob - but also artificial limbs and bones, architectural models, jewellery, bags and shoes.

Modern 3D printers can produce mugs, t-shirts and even chocolate

One of such firms is a Dutch design company Freedom of Creation, external.

Its product manager Bram De Zwart believes that 3D printing is revolutionising the way products are manufactured, distributed and commercialised, at the same time integrating the bespoke experience into our daily lives.

"Traditionally, products are much more pushed into the market with a lot of different marketing activities, and it leads to a lot of waste production," says Mr De Zwart.

"3D printing enables much more of a pull distribution instead of push, so consumers can buy products that are really tailored."

Indeed, he adds, what could be easier than choosing a highly complex design that has been done online and that could be extremely tedious, time-consuming and in some cases even too difficult for a traditional craftsman to produce - and getting it printed and then delivered to you?

Another interesting development is home 3D printing.

Same laws that govern plummeting prices and rising power of the PC apply to 3D printers - they are becoming cheaper and smaller, some costing under £1,000.

To use one, you either model your own 3D files or go online to a 3D-printing customisation website, choose what you like, and a 3D file will be automatically generated.

So maybe in a few years, we won't even have to go to a store in search of uniqueness.

We will simply create it with a click of a mouse and a 3D printer - right in our living room.