The firms planning on making less and recycling more

- Published

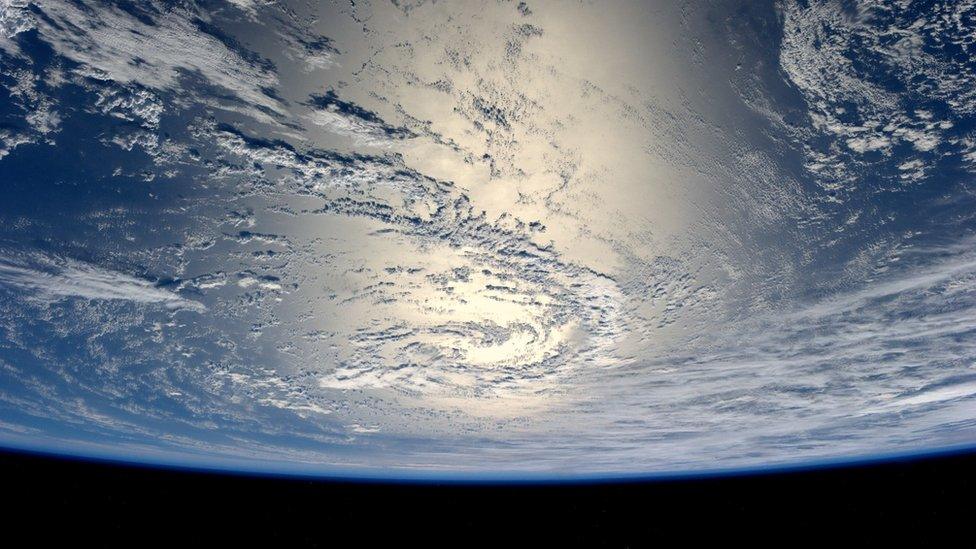

When using ever-increasing amounts of raw materials in a finite world, something eventually has to give

More and more firms are completely rethinking how products are made; redesigning them to make them more durable, easier to dismantle, repair and reuse.

Fundamentally changing the way we organise our current economic model is no easy task, but European governments and some of the continent's largest companies are waking up to the fact that profound change is needed.

Radical new concepts are rarely embraced with enthusiasm, but the circular economy could be an important exception.

The reason is simple; ever-growing demand, driven by population growth and wealth creation, cannot be met by the Earth's finite natural resources.

As the European Commission's Frans Timmermans has said: "Our planet and our economy cannot survive if we continue with the 'take, make, use and throw away' approach. We need to retain precious resources and fully exploit all the economic value within them."

Circular thinking

Our current, so-called linear, approach is unsustainable. In its place, we could adopt a more circular model, where the output of one process becomes the input to another; where the "waste" from one action becomes a resource for the next.

We currently waste huge amounts of natural resources

Indeed materials are currently classified as waste too early in the production process - perfectly good resources are simply discarded in favour of starting afresh.

By keeping these resources within the production process, a far greater value can be extracted from them.

As Ian Ellison, sustainability manager and Jaguar LandRover (JLR), says: "We have to look to nature, which has been making the most of resources and producing no waste for three billion years.

"Industrial processes have only been going 200 years and already we are bumping up against limits."

This is the essence of the circular economy, an idea that is gaining ever-greater traction as it moves from academia into the minds of policymakers and company directors across Europe and beyond.

Creating jobs

The European Union, which imports more than 60% of its raw materials, is leading the way.

At the end of last year the European Commission unveiled its Circular Economy Package, committing more than €6bn (£4.7bn; $6.8bn) in funding.

By 2030, the commission expects this to save the EU economy €600bn a year and be a powerful force for job creation.

There are two main components to it: The first redefines waste, allowing companies to make greater use of still-valuable resources that are currently discarded, and sets binding recycling targets for the next 15 years.

The second is an action plan that encourages far greater resource efficiency much earlier in the production process and includes an eco-design standard encouraging producers to design products with their end of life in mind; in other words ensuring that as many components as possible can be reused.

This will work as an extension of energy efficiency ratings already mandatory on white goods, explains Nick Molho, executive director at sustainable business group Aldersgate.

The action plan is not yet binding, but it could be very soon.

Dwindling resources

Legislation will be introduced "over the coming year, we are talking months", says Joss Bleriot, executive officer at the circular economy charity, the Ellen MacArthur Foundation.

"The European Parliament is massively supportive and business wants to do this, as they can see the competitive advantage."

Indeed the benefits to businesses are numerous. For a start they can save money from re-using natural resources rather than buying new ones, such as expensive rare-earth metals in the case of electronics.

This will become ever-more important as dwindling resources become more expensive.

Vast quantities of rare earth metals are used and then discarded in electronics

Re-using resources also insulates companies from volatile commodity prices, while reducing waste disposal costs and energy consumption.

Equally, it also should lead to less pollution and carbon dioxide (CO2) emissions that will increasingly become a cost to business as taxes are introduced to combat them.

The one major downside, of course, is that manufacturers may well sell fewer products if they are built to last longer and to be reused - but this simply means they will have to find different sources of revenue such as servicing.

In a world of finite resources, says Mr Bleriot, they will simply have no choice.

Saving money

A number of big companies are starting to embrace a more circular business model, including Unilever, Philips, Google, Ikea and BT. Indeed, according to Mr Bleriot, the most profitable car factory in Europe is Renault's remanufacturing plant in Choisy-le-Roi near Paris.

Another carmaker leading the way is JLR, which manufactures two of its three Land Rover models from aluminium, which is lighter than steel, giving improved performance and fuel efficiency.

The problem is it's more expensive and takes more energy to produce, thereby emitting more CO2.

Jaguar Land Rover is completely rethinking its production processes

For this reason, the carmaker has gone to great lengths to use recycled aluminium, known in the trade as post-industrial scrap. Half its aluminium is now from recycled sources, and JLR has set a target of 75% by 2020.

"Finding technical solutions and reorganising our supply chain has been difficult, but [buying less freshly smelted aluminium] saves us money," says Mr Ellison. "Economically, it pays off."

The company is now looking at its other top 10 most-used resources, from steel and magnesium to glass and plastics, to work out how best to source recycled materials.

Reusable buildings

Construction and support services giant Interserve is another firm looking at the circular economic theory to transform the way it does business.

Circular economic thinking is transforming the construction industry

Buildings are now not only dismantled rather than demolished and buried, with a view to reusing the raw materials, fixtures and fittings, - but are designed to be maintained, refurbished and repurposed more easily.

"That is the future," says Interserve's Mat Roberts. "The emphasis will be on modular and reusable buildings that can switch from commercial use, to residential, to healthcare, to office blocks."

He points to Sheffield University's Factory 2050, external as an example of what is possible.

Little choice

Circular economic theory is slowly but surely embedding itself at the highest levels of some of the world's biggest companies, and those implementing it first believe they are gaining an important head start on their rivals.

"If you want to save costs, reduce waste, cut your environmental footprint and improve revenue, you have to talk about circularity," says Mr Ellison.

"It is the only model that resolves all the different tensions [facing businesses]."

Finite resources may mean companies ultimately have no choice, but many believe embracing the circular economy now also makes perfect business sense.