The secret supplier to the world's top designers

- Published

Ubrique is beautiful but remote

The town of Ubrique in southern Spain is beautiful but remote. It doesn't have an airport or a train station and even buses are irregular.

Its position, nestled at the bottom of a valley surrounded by big hills, means the easiest way to get there is by car. But even then drivers have to navigate winding and often steep roads.

The town is around 75 miles south of Seville, nowhere near the world's fashion capitals of Milan, Paris, New York or London.

Yet this collection of whitewashed houses, known as a pueblo blanco (white town) in Spanish, is where many of the top fashion brands source their leather goods.

Louis Vuitton, Gucci, Hermes, Chanel, Chloe, Loewe and Carolina Herrera are all reported to use the artisans here to make things such as handbags, wallets and belts.

The factory workers can't talk about the brands they produce goods for

Yet almost none of these designers is willing to talk about it.

Most of the secrecy comes from the fear of someone using the high end designs to produce cheap copycat products, a costly problem for luxury retailers.

Juan Antonio Sanchez, manager at leather goods manufacturer Ranchel, says the big brands often have strict demands.

"We have to sign a contract of confidentiality, then the factory, the manager and every worker have to sign it.

"They have an individual contact and they cannot take pictures, they cannot take the designs or anything to do with the products," he explains.

Mr Sanchez's firm, which was started by his father, has now been making leather items for over forty years.

But the town's specialisation in leather goes back much further than this.

Ubrique's focus on leather goes back centuries

It started more than 200 years ago, initially with tanning leather. Eventually this evolved into the precise leatherwork which the town has become so well known for.

Now the leather is bought in from elsewhere, already tanned and those in Ubrique focus on the more skilled manufacturing work.

Today more than half the town's residents work in the leather trade, producing the majority of leather goods sold in the country as well as supplying many big overseas fashion houses.

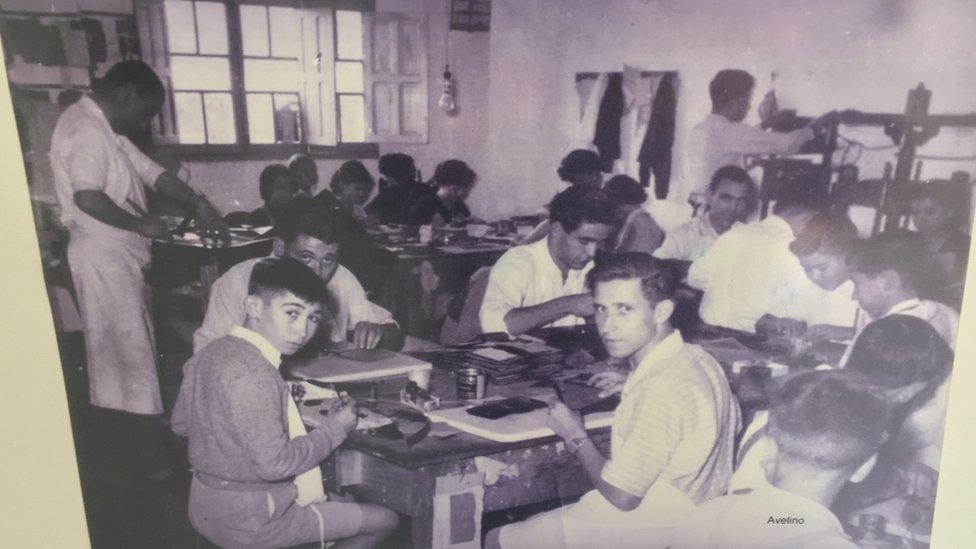

The techniques needed to produce such goods at the top end of the quality scale has been passed down from generation to generation.

Mr Sanchez says most in the town learn these skills when they're young by watching their parents as they work.

"That technique it can only go from father to son, because it's very specialised. Kind of they have it in their blood," says Mr Sanchez.

Many of the factories refuse to use an assembly line to speed up the manufacturing process

It's these kind of skills, honed over generations, which have drawn in the big brand names.

Word of mouth is often how designers have found out about Ubrique.

Jose Urrutia, founder of high end shoe and accessories firm La Portegna, says an acquaintance told him about the town.

"I asked them for some samples and I was blown away by the quality of the stuff they made," he says.

For Mr Urrutia the town's history and the way the trade has been passed on through generations is also part of the attraction, because it helps him create a story around his brand.

He says the idea for the firm came from his grandmother - a keen traveller who'd befriended the writer Ernest Hemingway on her exotic round-the-world trips.

Jose Urrutia says this kind of craftmanship is dying out

Browsing her photos made Mr Urrutia nostalgic for a bygone era when items were special and treasured.

He wanted to try and create the same feeling with his company's products.

"In Ubrique what they're very good at is helping you because they have tons of experience. They've been doing this for centuries."

He says this kind of slow but precise artisanship is dying out and increasingly hard to find elsewhere.

'Dying'

"The whole concept of craftmanship is dying. The beautiful thing about this place is that it's not just one street or a couple of houses. It's an entire village."

He acknowledges that he could find cheaper, larger manufacturers elsewhere, but says that's not the point.

"There's always been a notion of the economies of scale but that doesn't work that well here. A good bag needs x amount of hours. You can't cheat your way into it."

While some of the factories here have started to use an assembly line to speed up the manufacturing process, many have refused to compromise.

Some in the town believe there should be a "Made in Ubrique" label

Jorge Oliva Perez, general manager at local leather brand El Potro says a single worker still makes the entire bag, bar the cutting and the design.

"It's very important to hold onto these skills," says Jorge.

Like many of those working here, Jorge would like this expertise officially recognised with - a "Made in Ubrique" label.

"I think it's very important for our future," he says.

The town's artisans are having to compete with cheaper rivals elsewhere

It could also help the town with the ever present threat of cheaper rivals moving into their territory.

It's already happened once. Around a decade ago - at about the time of the financial crisis - the manufacturers here suffered a dramatic drop in orders.

Many of the big brands had decided to cut costs by switching supplier - in most cases shifting orders to China or elsewhere in Asia.

While orders from cheaper brands continued, there was less work overall which meant some people lost their jobs and went into other industries.

The fact the products are handmade means each one is subtly different

Nonetheless, Ubrique's councillor for culture Jose Manuel Fernadez Rivera says most workers "kept working because they knew that their quality was better and they were going to come back".

It turned out to be true. A year later, most of the big brands had returned.

"The Chinese learn very fast but we know that the quality, the detail that we give in every piece, which is what the brands ask for, they're not going to get that," he says.

The other issue that drove the brands to return to a European manufacturer, was that a bag made in Asia was a tough sell to some of their biggest customers - those living in Hong Kong, China and Singapore.

When they're paying hundreds, or in some cases thousands of euros, to buy a bag from a top Italian and French designer then they expect it to be made there not in their home country.

And of course they also expect that artisan touch.

"In this business you have to work with your hands. Every product is different because you do it one by one," says Mr Sanchez.

This feature is based on interviews by series producer Neil Koenig, for the BBC's Life of Luxury series.

- Published24 July 2017

- Published17 July 2017

- Published10 July 2017

- Published3 July 2017