Why your new heart could be made in space one day

- Published

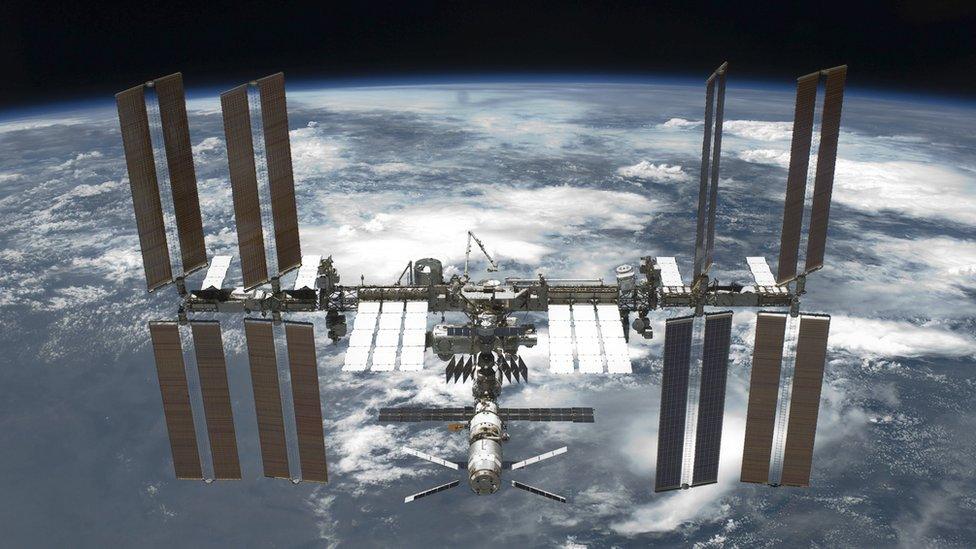

The International Space Station could become a factory for specialist materials

Imagine a laboratory growing human hearts - and imagine that laboratory floating in space hundreds of miles above the surface of the Earth.

That may sound like science fiction, but bizarre as it seems, it could bring new hope for transplant patients within the next decade.

While about 7,600 heart transplants were carried out around the world in 2017, there's a desperate shortage of organs, with thousands of people on waiting lists dying every year.

Efforts to grow human hearts in the lab are showing promise, but are hampered by the need for the organs to grow around a "scaffolding" to make sure they don't collapse during the process. Reliably removing the scaffolding once the heart is complete is proving to be a challenge.

Space tech company Techshot believes zero gravity could be the answer.

The International Space Station (ISS) is in constant freefall around the planet, meaning that anything inside experiences effective weightlessness, known technically as microgravity.

Could Techshot's BioFabrication Facility grow human hearts in space one day?

This means organs could be grown without the need for any scaffolding, believes Rich Boling, the firm's vice-president of corporate advancement. One day hearts could be grown commercially for transplant, Techshot believes.

"Our ultimate goal is to provide a solution to an organ shortage that causes an average of 20 people per day in the US alone to die waiting for an organ transplant," he tells the BBC.

"Getting to that point is a journey of a thousand miles, and launching our BioFabrication Facility to the ISS is that first step."

Developed in partnership with Nasa, Techshot's BioFabrication Facility (BFF) is a microwave oven-sized device that uses 3D printing techniques to create patches for heart repairs using a patient's own stem cells.

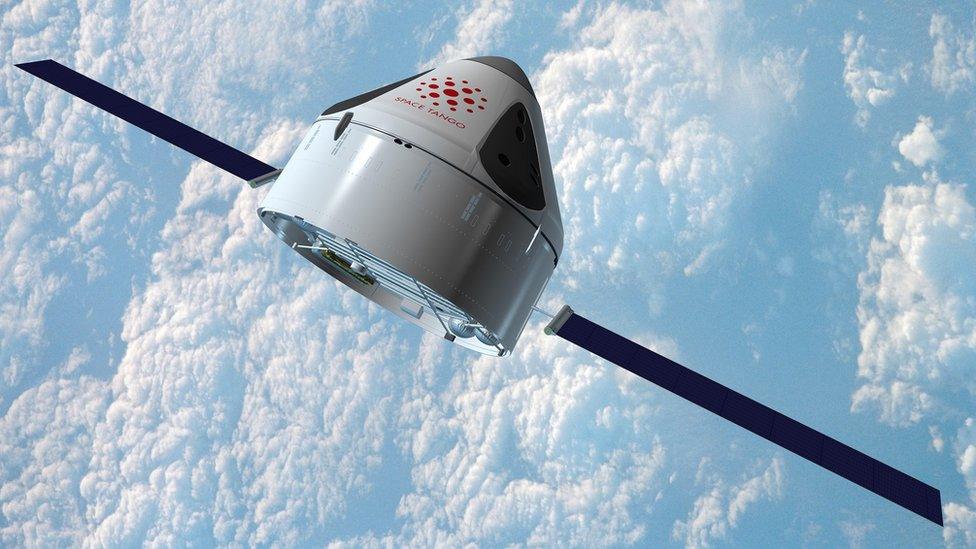

Delivery craft, similar to SpaceX's Dragon cargo capsule, could ferry goods to and from space

It's due to launch to the ISS on SpaceX mission CRS-18, scheduled for May this year.

Ultimately, the aim is to grow complete human hearts in space.

The first year will be spent putting the BFF through its paces to check that it is functioning as designed, before test printing starts in earnest.

"Our initial tests will focus on printing cardiac tissue," says Mr Boling. "After our test protocols have been completed, we'll open the program up to outside researchers who want to use our device.

"Then we'll bring BFF back to earth and make whatever modifications may be needed to optimise it based on what we've learned during the test phase; then we'll send it back up with the goal of manufacturing increasingly complex tissues."

All this will take time, of course, with manufacturing of whole organs not expected to start before 2025. Achieving regulatory acceptance of the manufactured organs could take a further 10 years, the company believes.

Leaving aside the practical challenges, how could it ever make commercial sense to grow human organs in space?

SpaceX's Falcon 9 rocket returned safely to earth in December 2015 after launching a satellite

Elon Musk's disruptor company SpaceX is markedly reducing the costs of space travel, but even its cheapest rocket still costs nearly $60m (£47m) per mission. And it is only just getting to grips with the difficult task of bringing rockets safely back to earth.

But Mr Boling maintains that "an organ manufactured in space from the patient's own stem cells will not require anti-rejection drugs. Therefore, the overall lifetime cost for a single transplant is expected to be lower for the patient receiving an organ manufactured in space than the alternative."

But manufacturing usually demands high volumes of goods made to reduce costs. How can you achieve such scale in space? The ISS isn't exactly huge.

US start-up Space Tango is rising to this challenge with the launch of a series of autonomous manufacturing facilities, known as ST-42, that will orbit the earth from the mid-2020s onwards.

Space Tango's ST-42 mini space factories could be in orbit within 10 years

Each unit will be a couple of metres across, and will remain in orbit for 10 to 30 days before returning to Earth with the products it has made.

"We are focusing on materials such as fibre optics, silicon carbide and carbon nanotubing," says Space Tango chief executive Twyman Clements. "We are also focusing on pharmaceutical applications."

Removing the stress of gravity means fewer imperfections in the manufacturing process.

For example, Californian start-up Made In Space is working with Nasa to produce a type of optical fibre called ZBLAN.

First discovered back in the 1970s, ZBLAN is a fluoride-based glass that can be produced with almost no impurities, performing 10 to 100 times more efficiently than traditional silica optical fibre.

Space-bound manufacturing units have to be very robust

But when it's produced on Earth, gravity-driven forces such as convection cause crystals to form in the fibres, damaging signal quality and making it impractical for long-distance use.

In microgravity, a much purer, more efficient fibre can be produced. The team has already had test runs producing more than 100m (328ft) of cable.

"We're continuing to develop the hardware to get to commercially usable and saleable quantities of fibre," says chief executive Andrew Rush.

This could be done on the ISS itself, he believes.

"Or we could make it on a commercial space station, a module that's attached to a space station, or on a free-flying module. For each one of these options the economics is different, but there are a lot of options."

In the long term, says Mr Rush, there are many different products which, even with current launch costs, look to be economically viable to produce in space - carbon nanotubes, specialist metals and human tissues, to name but a few.

This raises the possibility of a series of factories free-wheeling about the Earth producing entirely new classes of hi-tech materials.

"There's a long road between here and there," he says, "but these technologies could ultimately help industrialise space - and give people a reason to go and live there."

Follow Technology of Business editor Matthew Wall on Twitter, external and Facebook, external