'I've lost £20,000 in sales because of shipping delays'

- Published

Toy store owner Hellen Stirling-Baker says container delays have cost her £20,000 in sales so far - 40% of her annual turnover

Delays at UK ports mean a number of toy orders will now miss Christmas, according to the British Toy and Hobby Association (BTHA).

The industry body has called on the government to help "save the festive season" by easing port congestion.

Hellen Stirling-Baker, who runs a Sheffield shop, says she has lost £20,000 in sales because of container delays, or 40% of her annual turnover.

Other shops say it is impossible to order some popular toys including Lego.

Ms Stirling-Baker has been told that her order of cotton Dinkum Dolls, made in China, won't arrive in England until 7 January. The British company that designs the dolls told her their container is held up in customs, but it's already experienced seven weeks of delays due to the pandemic, port congestion and other logistics issues.

Other toy orders from Ms Stirling-Baker has made have arrived incomplete.

"I just received an order today which I placed three weeks ago, and only part [of it] has come. The rest is stuck in ports," she said. "Demand has been really high but stock levels are low."

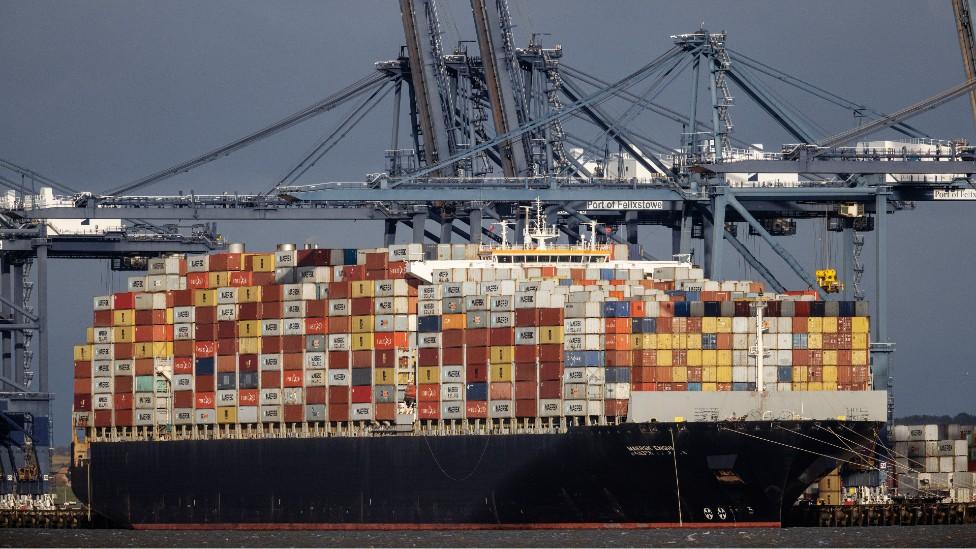

While many UK importers are struggling with the congestion issues at Felixstowe and Southampton, the toy sector has been particularly hard hit, since the problems have coincided with the peak Christmas season.

The Leeds-based toy designer Boxer Gifts, which manufacturers its products in China, estimates a loss in sales of up to £1m this year due to stock delays.

Managing director Thomas O'Brien says one of his containers is currently stuck in the Belgian port of Zeebrugge and there's no way it will get to the UK in time for Christmas.

"Some of the ships are bypassing the UK and tipping off at European ports, but others are just slowing down because they've got nowhere to unload," he said.

"Various games and stocking-filler toys such as Grow-a-Sloth are hugely popular, but we've had stock outages for months because shipments are delayed and that's costing us sales.

"More importantly it's reducing availability for consumers to find fun gifts. There's less about."

Toy designer Boxer Gifts says lost sales from shipping delays will mean less money for innovation next year.

Like many importers, Mr O'Brien has also had to contend with a sharp rise in shipping costs, as shipping firms hike up freight rates in response to port congestion and a shortage of empty containers in Asia.

He says containers shipped from Qingdao, China to Felixstowe are costing him $10,000 (£7,492.03), rather than the normal rate of $2,500.

'Save the festive season'

BTHA has called on the government to help where it can.

"We would urge the government to help at this crucial time for business, to save the festive season and alleviate blockages now ahead of the UK's departure from the EU," said a spokesman.

Adding to the calls for government to intervene at the ports are the British Retail Consortium (BRC) and the Food and Drink Federation (FDF). The two trade bodies have written to MPs to request an urgent inquiry into the ongoing disruption at UK ports and skyrocketing shipping rates.

A spokesman for the Department for Transport (DfT) said: "This is not a problem unique to the UK, with ports around the globe experiencing similar container capacity issues. The government is working closely with the freight industry to work through the challenges some of our ports are facing.

"Ports are employing more staff, as well as working with hauliers to improve container collection and with shipping lines to maximise efficient utilisation of port capacity. We will do everything we can to resolve the situation as quickly as possible."

While many small toy shops are struggling, some larger toy retailers say they've managed to avoid problems at the ports by stockpiling early in the year. Many have also benefitted from booming toy sales as families spent more time at home during coronavirus lockdowns.

ToyTown, which has 30 outlets across the UK, says it has had a bumper year with especially high orders of puzzles and games.

"We took a decision to load up pre-Brexit - if companies run a 'just-in-time' model, they'll suffer," explains managing director Alan Simpson.

He says it is typical for some toy lines to run-out of stock before Christmas, but this year's port problems are "limiting choice" for retailers, and he's had to closely monitor his supply chain.

Charlotte Khan and her husband Naveed run a toy store in Folkestone

Charlotte Khan from children's boutique Moo Like a Monkey in Folkestone, Kent, says her business has had to be "more resilient than ever this year".

After losing thousands of pounds due to shipping problems that have left her having to hold onto late-arriving stock for next year, she is planning to refocus on stockists much closer to home.

"I'm going to look much more locally for suppliers now, they're the ones who've kept us in more reliable stock," she said.

"Even though we've taken a hit on our Christmas turnover, we've dealt with worse this year, and at least we've been able to trade during our peak season. I'm grateful to still be in business."

- Published13 December 2020

- Published9 December 2020

- Published13 December 2020