Nike trainer output at key factory hit by Covid outbreak

- Published

Production at some of Nike's largest plants in Vietnam has been disrupted as Covid has spread through factories.

The company refused to comment on whether store supplies would see shortages as a result of the outbreak.

About half of Nike's shoes were manufactured in Vietnam in the last financial year, so this will mean challenges for its supply chain.

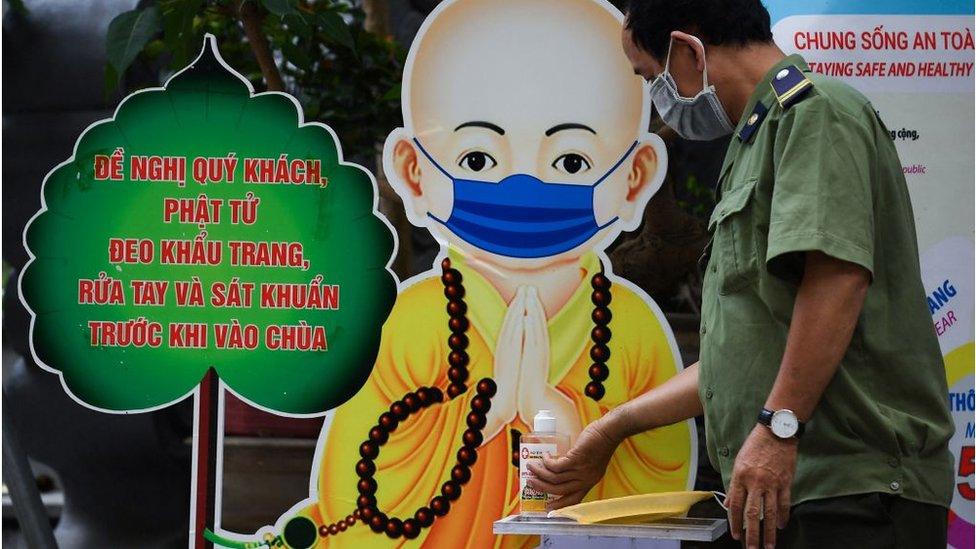

Vietnam has seen a record rise in cases since last April with many infection clusters in its industrial provinces.

Apple, Samsung and Puma could also be affected by the surge in cases recorded at suppliers' factories in the country.

"The health and safety of our teammates, as well as that of our suppliers, remains our top priority," a statement from Nike said.

Nike said the company would continue to work with its suppliers to support them in response to the rise in Covid cases.

"We are confident in Nike's ability to navigate these near-term dynamics, and we remain prudent in our planning," the statement added.

One of Nike's worst affected suppliers in the region, Pou Chen Corp, also makes footwear for Adidas and is the world's largest manufacturer of branded trainers.

It suspended operations at its plant in Ho Chi Minh City on Wednesday due to the outbreak in infections.

In a statement, the country's health ministry said Pou Chen's Pouyuen Vietnam factory would be suspended for 10 days.

The factory is Ho Chi Minh City's largest employer, with a total of 56,000 workers. But it was unable to stay open and arrange for its workers to sleep at the factory, as was required by authorities to limit the spread of infections, according to the health ministry.

Nike employs over 450,000 workers in the country, 80 % of whom are women.

Similar challenges could also be faced for Puma, whose footwear is also manufactured in the country. Apple and Samsung also have large suppliers in the worst affected factories in the northern region of Vietnam.

Apple did not give a comment on whether the outbreak will mean item shortages in shops, while Adidas, Puma and Samsung did not immediately respond to the BBC's request for comment.

Samsung makes around half of its phones in Vietnam and has had to stop work at three factories in Ho Chin Minh City. According to the health ministry's website, Samsung Electronics is planning for workers to sleep at the plants and has currently cut its staffing to 3,000 from 7,000.

Many firms had begun to move their production from China to countries such as Vietnam as a result of challenges from tariffs over the course of the pandemic.

Dr Patsy Perry, senior lecturer in fashion business at Manchester Metropolitan University, told the BBC these problems are compounded by the Covid-related surge in demand for athletic wear as people have been spending more time at home.

"This shows the risk of overreliance on a particular sourcing region," she explained.

Bu, Dr Perry said that Nike's manufacturing map means it could potentially move production the other countries, depending how agile its supply chain relationships are.

"Costs might increase in the short term if it needs to move production into more expensive areas, but it's more important to service demand than risking a stock-out situation," Dr Perry added.

Dr Steve New, professor of operations management at the University of Oxford's Saïd Business School, told the BBC that previously, because Vietnam has been effective at containing Covid, it has been able to respond rapidly with short local shutdowns. But he said that as the situation worsens, "it will be much harder to pursue this approach without much more significant disruption to the supply chain."

Vietnam has vaccinated around 4% of its 100 million population. Its capital Hanoi has stopped all non-essential services due to new clusters of Covid infections and on Sunday urged its citizens to stay at home.

The government added factory workers to its vaccine priority list after the rise in cases in late April forced manufacturing areas in the north of the country to close.

Related topics

- Published31 May 2021

- Published25 June 2021

- Published13 July 2021