Biochar: Running the numbers

- Published

In search of a "magic bullet" for climate change that will simultaneously help with the growing problem of feeding the world, gurus from James Lovelock downwards have praised the potential of biochar.

"I said in my recent book that perhaps the only tool we had to bring carbon dioxide back to pre-industrial levels was to let the biosphere pump it from the air for us," the originator of the Gaia concept told The Guardian newspaper last year.

"We don't need plantations or crops planted for biochar, what we need is a charcoal maker on every farm so the farmer can turn his waste into carbon."

But will farmers want to? Will it be worth their while?

Dr Lovelock would presumably be encouraged by developments at Stonelaws Farm in Scotland, whose owner Colin Hunter is taking a close look at the potential and pitfalls of biochar, in conjunction with researchers from the UK Biochar Research Centre at nearby Edinburgh University.

The project is helping to answer some of the big outstanding questions: for how long does biochar lock carbon into the soil, how much benefit does it produce for crops, how does it stack up against other uses for waste, and how can it be tailored to produce maximum benefits?

And those answers in turn could help determine whether biochar does turn into a worldwide phenomenon, or whether it eventually finds its way into the bin marked "Good Idea - But..."

Winning ways

At first sight, the case for biochar seems unanswerable; a win-win-win-win-win situation.

Modern biochar production is a more efficient variant of tradition charcoal making

Plant waste is heated to temperatures of several hundred Celsius in a pyroliser, a vessel from which oxygen is excluded; so it does not burn.

Instead, gases and liquids are driven off, which can potentially be used as fuel or agricultural treatments.

The remainder turns into a dry, carbon-rich solid similar to charcoal.

Scattered on fields, biochar helps raise crop yields; and the carbon it contains is locked away for thousands of years.

As that carbon had been absorbed from the atmosphere as the plants grew, what we have is a net removal of carbon from the atmosphere and storage in soil.

So we have improved crop yields, carbon storage, virtually free fuel, waste disposal and potentially extra earnings for the farmer as well; what is not to like?

Academic backing emerged a few months ago with the publication of a study showing that biochar could absorb 12% of humanity's greenhouse gas emissions - not a complete bullet, perhaps, but certainly a valuable weapon for the anti-climate change armoury.

On the other hand, bad experiences from the "race to biofuels" and the UN's Clean Development Mechanism (CDM) mean there are concerns that biochar could be practised, or rewarded, inappropriately, with "perverse incentives" emerging that could reward logging for biochar or the indiscriminate spreading of char on crops that would not benefit.

Hence the need for more research.

The technique is being adopted on a small scale in many countries, but many of the basic questions remain unresolved - hence the importance of the Stonelaws Farm site.

"I was brought up on a farm and we had an 'ash field' where we used to take ash from houses in the village and put it on the field," Mr Hunter recalls.

"That was a much more fertile part of the field than the rest, and there was some charcoal in the ash and obviously it was having an effect. So I wanted to see if that could be replicated."

Hence his enthusiasm for hosting the biochar project, run by Jason Cook.

Machine head

The char is made in what looks at first sight like a boiler - a machine about as tall as a person, adorned with pipes, a bucket hanging from one of them.

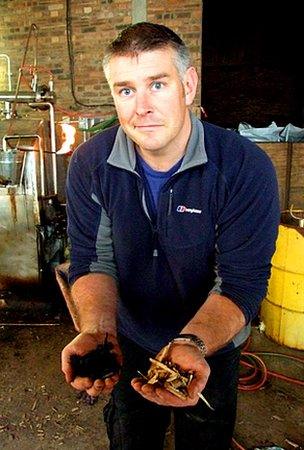

Left hand fuel, right hand biochar... Jason Cook at Stonelaws Farm near Edinburgh

It is a pyroliser - Indian-made - a fairly low-tech item designed for practical use rather than fancy laboratory experimentation.

Jason shows me the raw material - fragments of Scots pine or willow - and the blackened, dry residue it turns into during its voyage through the pyroliser.

Then he dumps a sackful of wood into it, locks down the lid to keep the air out, and fires the beast up.

For the next 20 minutes or so we see the temperature rise to several hundred Celsius - he has taken it as far as 650C.

Gradually, puffs of something appear from the pipe. Not smoke, because the wood is not burning - rather, the first of the gases that are being driven off, mostly water vapour with a cargo of brown stuff.

Meanwhile, the first liquid emerges from the consenser pipe - a pungent, oily brew that can be used as a herbicide.

Jason then holds a match to the gas pipe and it struggles into a flame, becoming more stable as the proportion of methane and hydrogen rises with the temperature.

"The next stage is to collect the gas and get it analysed back in the lab, and get the calorific value," Jason explains.

"We want to see if there's an optimal temperature where we're getting the most valuable flammable gas coming off."

Colin Hunter spends about £20,000 per year on gas that is burned to dry grain - and one of the benefits of pyrolysis could be to produce enough gas that he can keep this money in his pocket.

On fertile ground

The solid left at the end of the pyrolysis process is spread on fields to see whether biochar does boost crop yields as claimed.

"I'm harvesting with a combine harvester that combines GPS tracking with very accurate yield measurement, so we can get a very good view on this," Jason relates.

"Last year we spread 10 tonnes per hectare on spring barley, and got a statistically significant yield increase of 7%."

More recent results indicate that higher yield increases are possible, but also that there is a threshold; spread too much, and the yield goes down again.

What complicates the analyses of these effects is that it is not entirely clear what biochar does in the soil.

"It's largely carbon and very porous, so maybe it's creating a home for microbial communities," Jason says.

"It may also aerate the soil and assist with water-logging.

"The carbon has got a nutrient value itself, and it's been shown to stop some other nutrients like nitrates leaching away, which suggests using it is going to allow you to reduce the amount of fertiliser you need."

Bespoke biochar

The labs at Edinburgh University hold a cache of samples that may, in time, show how to make biochar for maximum impact: how hot to run the pyroliser, how long to leave the wood inside, and what sort of soils and crops will benefit the most.

"The higher the temperature, the more of the volatile liquids and gases you drive off, so the lower yield of char you get," explains researcher Pete Brownsort.

"But it may be more stable char - or it might not be - that's a big question at this time.

The pyroliser produces flammable liquid and gas, which could be used as fuels on the farm

"At this centre we have the concept of 'bespoke biochar', which is an idea of producing the char that's going to have the exact properties you'll need in the field where you're going to use it."

According to this vision - developed by Edinburgh soil scientist Saran Sohi - you could give farmers a recipe book allowing them to make precisely what char they need, bearing in mind that they may be looking for a balance of yield increases from the char and fuel from the gas and liquid.

Potentially this could also allow authorities to reward farmers for capturing and storing carbon - and to know how much they should pay the farmers.

In the case of Stonelaws Farm, the economics are as yet unclear, according to Colin Hunter - and complicated by the fact that farm waste going into the pyroliser could instead be burned, producing a greater dividend in heat and potentially in electricity generation too.

"You'd have to be seeing fairly dramatic increases in crop yields, otherwise you'd say 'well we'll just chop up the straw and put it back on the fields instead of bringing it in, heating it and taking it back out again'," he says.

"The other aspect to this though is carbon credits.

"If we could earn carbon credits for this, it would transform the viability; and if we generate electricity, do we qualify for the feed-in tarriff?"

Research at Edinburgh and elsewhere has shown that the carbon economics of biochar can stack up rather well.

In contrast to burning, about half of the carbon in the waste is captured and stored; meanwhile, the liquids and gases yield easily enough energy to power the pyroliser, with some left over for other uses around the farm.

But you sense biochar will take off only if and when farmers believe they have something to gain from it economically as well; and on a global scale, that case remains complex and unproven.

You can find out more about the potential of biochar and other technological "climate fixes" in this week's edition of One Planet on the BBC World Service.

- Published24 August 2010