Stain-shedding coating gets tough

- Published

This video shows what happens when a water droplet hits a sample of the "self-cleaning" coating. Courtesy of Tong Lin/Deakin University

Chemists have devised a better method of coating fabrics with a water-repellent, "self-cleaning" coating.

Many such "super-hydrophobic" coatings have been made before, but a <link> <caption>report in the journal Langmuir</caption> <url href="http://pubs.acs.org/doi/pdfplus/10.1021/la300281q" platform="highweb"/> </link> describes coated fabrics that are far more durable.

The trick was to engineer a multi-layered coating whose layers, when struck with UV light, bond more firmly to each other and to cotton.

The technique also may also be put to use in medical antibacterial coatings.

Super-hydrophobic surfaces have fascinated scientists for years; they are behind the lotus plant's self-cleaning leaves and the <link> <firstCreated>2000-06-07T18:17:34+00:00</firstCreated> <lastUpdated>2000-06-07T19:17:09+00:00</lastUpdated> <caption>gecko's super-dry and thus super-sticky feet</caption> <url href="http://news.bbc.co.uk/1/hi/sci/tech/781611.stm" platform="highweb"/> </link> .

These surfaces are practically impossible to wet - water beads on them and dirt and particulates do not stick to them, leading to the self-cleaning description.

Chemists looking for the next best thing in clothing coatings have tried several tricks in recent years to create a coating with similar properties in the laboratory.

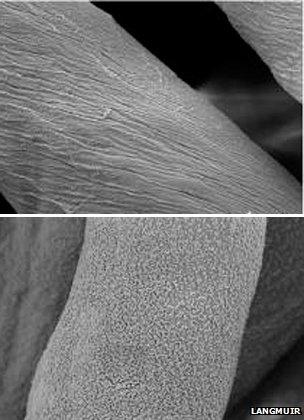

Uncoated fibres (top) and fibres coated with multiple layers of silica nanoparticles - the same stuff as sand

The new work hinges on what is known as layer-by-layer self-assembly - basically dipping a fabric into a solution over and over again to deposit multiple layers on it.

The team from the Australian Future Fibres Research and Innovation Centre at Deakin University made their solution with tiny particles of silica - the same material as sand.

Crucially, they added a few chemical steps to coat the particles with long chemical tails ending in what are known as azido groups.

The team found that layered coatings of the azido-treated nanoparticles were, like many previous attempts, not very durable - a stain-free shirt with such a coating would not survive many washes.

But baked under a source of UV light, the tails on the particles were made to interlink with one another, forming a far tougher structure within and across the layers.

"This technique is simple, but allows forming an [even] coating on irregular [materials] having a complicated surface structure, and it can precisely control the coating thickness," said Tong Lin, lead author of the work.

Dr Lin told BBC News that at this stage, the technique is only suited to small samples, but that it is just one of a number of similar approaches in which a self-cleaning surface is desirable.

"We have also used a similar method to apply a soluble antibacterial agent to a three-dimensional tissue scaffold for biomedical applications," he explained.

"The coating is stable... but has a strong antibacterial performance; however it does not interfere with cell growth."