Bloodhound Diary: Partnership made in China

- Published

A British team is developing a car that will be capable of reaching 1,000mph (1,610km/h). Powered by a rocket bolted to a Eurofighter-Typhoon jet engine, the vehicle will first mount an assault on the world land speed record (763mph; 1,228km/h). Bloodhound, external should start running on Hakskeen Pan in Northern Cape, South Africa, in 2017.

Exactly 12 months ago we held the public launch of the nearly completed Bloodhound SSC in the centre of London.

We were swamped by the media (over £100m of global coverage for the launch) and the general public, with some 8,000 people packing out our Canary Wharf venue during the two brief days that the car was on show.

It was obvious that we had a winner; now we just had to find the right partner to help us get it finished.

This has taken a little longer than we’d hoped, but finally we are able to announce our new Lead Partner, Geely, external (technically, it’s the Zhejiang Geely Holding Group, but let’s keep it simple – Geely).

If we were choosing an ideal new partner, we’d look for someone that would understand Bloodhound's mission, external as "an Engineering Adventure" to inspire the next generation’. Better still, we’d look for someone to help us put the Bloodhound Engineering Adventure in front of millions of people we haven’t reached yet.

Now here’s the good bit: the Geely Group makes cars (inlcuding Geelys, Volvos and London Taxis), the Group runs research and development centres around the world (including one in Coventry), and it’s also set up a number of universities in China.

This is a company that clearly understands the technology and the education mission of our story.

Following our recent press launch, Bloodhound is fast becoming big news in China and I’ve had two email enquiries already from the British Embassy in Beijing.

Thanks to this new partnership, we’re starting reaching out to country of well over 1.3 billion people, as well as the other countries in the region. We’ve only just started working together, but Geely already seems like a great partner for Bloodhound’s Engineering Adventure.

Bloodhound in New York

We’ve had a lot of texts, emails, tweets and notes of congratulations since we announced our new partner, as well as lots of "about time – when’s it running?" comments.

My personal highlight was seeing a picture of Bloodhound SSC, and our announcement about Geely, on a billboard in Times Square in New York.

From Beijing to NY, there is no escape, Bloodhound is coming to get you. Thanks to all of you who wrote in and yes, I do know just how you feel, I can’t wait to see it running either!

As well as helping to promote our adventure around the world, Geely is keen to make some technical contributions to Bloodhound.

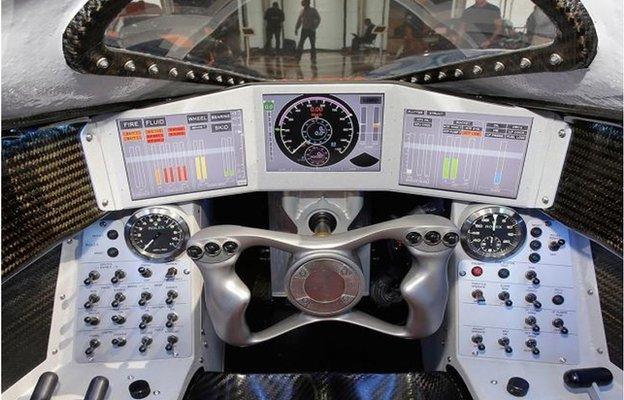

For example, we’re now working with the company’s engineers to see how they could help us with finishing off the cockpit. Fitting our high-tech sound-proofing is a key job, as one of my big concerns is the huge noise level, caused by the supersonic shockwaves on top of the car, which will reverberate through the carbon-fibre cockpit structure.

Slightly worryingly, we’re not exactly sure how noisy this will be (not really surprising, since no-one has ever done 1,000mph in a car).

The acoustic energy (noise) levels could be enough to stop the cockpit instruments from functioning properly, never mind what it will feel like for me, so from my point of view the sound-proofing is a critical part of the finish.

Hoping for a quiet office

The colour of the interior is also fairly important, to make the cockpit as easy to use as possible.

Here’s a simple example. You’re probably reading this as black text on a white background, which works well for text, but the black/white contrast can be a bit much for complex information.

Instead of the high contrast ratio (e.g. BLACK/WHITE or WHITE/BLACK), a lower contrast (e.g. incorporating grey) generally works better and looks less "cluttered" for high-tech instruments.

Any colour as long as it’s grey

This is the science behind modern jet fighter cockpits and I’ve used the same approach to designing Bloodhound’s cockpit. Using the wrong colours can also make things difficult, as it can create an effect called chromostereopsis.

People have been using colour like this for many years (it’s been used in stained glass windows for centuries), but it doesn’t make it easy to read labels or instruments, so we need to avoid it. I know how I want Bloodhound’s cockpit to look when it’s finished, now we need to work out how to make it happen.

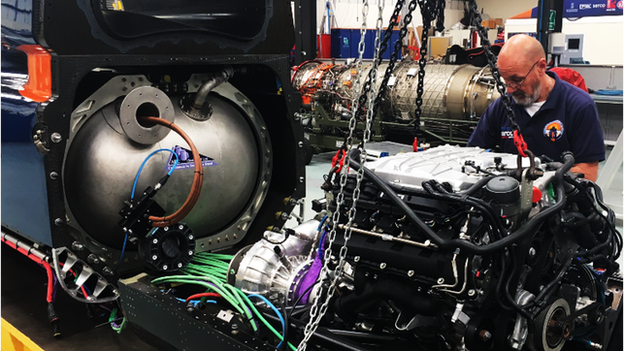

Those of you who watched our live press event online recently will have noticed that we sat the media down in front of our full-sized show car, not the real thing. The real car is already being stripped down, external, so that we can finish off the last of the 3,500 pieces that go to make up Bloodhound.

Each piece of the car is being painstakingly removed, inspected, finished if required, and then tagged and put into our stores. Once this process is complete, we’ll reverse the whole thing and start the final build. It’s this attention to detail that makes it possible to build and run a 1,000mph car safely.

Taking it all to pieces

Attention to detail is equally important for our desert track in South Africa, external.

After the truly heroic effort that the Northern Cape Government team has put into clearing the track for us over the past seven years, I’m off to Hakskeen Pan to have a look at the finished product.

I haven’t been out there for a couple of years, so a lot has changed since I was last working on the track (have a look at a short video clip here, external).

Our team has been sending back glowing reports of the finished track surface, so we’re really looking forward to seeing the 20-plus million square metres of hand-cleared surface, on what has to be the best straight-line race track in history. More to follow next month.

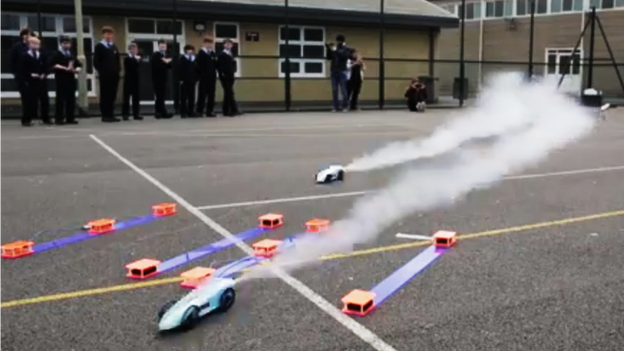

This year’s model rocket car competition, external was a huge success, with over 5,000 teams from across the UK taking part, and the Santa Pod finals including a "demo" run of 522mph by Joseph Whitaker School (if you haven’t seen it, have a look at this video, external – wow!).

Eyes like dinner plates

As our chief engineer Mark Chapman simply put it: "There’s nothing more exciting than building your own car, putting a rocket in the back and firing it. The kids’ eyes are like dinner plates."

Next year we’re planning an even more ambitious programme, with 25,000 rocket car kits available, and a first prize of the chance to see Bloodhound SSC run in South Africa next year. Book here, external now to make sure you receive your free rocket car kit, as the entry list will close at the end of October.

And if you fancy having a go at Joseph Whitaker School’s record, there’s still time to make sure that the world’s first supersonic rocket car run happens in a playground near you. Good luck, we’ll all be watching!

How fast can you go?

- Published26 September 2016

- Published29 July 2016