3D printing offers ability to print physical objects

- Published

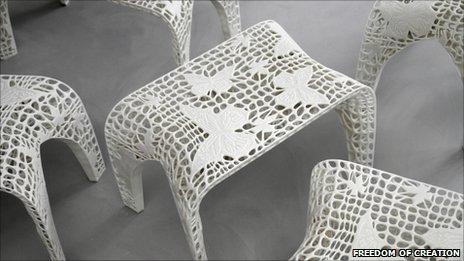

Soon tables like these will be available to download and print in your home

As Christmas fast approaches, millions will opt to spare themselves the crowded high street and instead settle down in front of the computer and do their shopping there.

Yet buying online has always had one key disadvantage: you have to wait.

Not only that, but the inability to touch a product, try it on, feel how heavy it is or do anything else you would do on your typical high street excursion prevents online shopping being the perfect experience.

But technology is now coming online that could allow you to receive your goods straight away.

As the cost of 3D printing hardware begins to drop, bespoke, printable products may be about to hit the market.

Fashion potential

Freedom of Creation is a design and research company exploring the capabilities of what, in the industry, is known as rapid prototyping.

Janne Kyttanen is the company's founder and creative director.

"Imagine the potential of this for the fashion industry," he told Digital Planet on the BBC World Service.

"I can measure your body, in 3D, and I can make you perfectly fitting garments in the future without any sewing and stitching, making the needle and the thread obsolete."

His company is now producing products for companies including Asics, Tommy Hilfiger and Hyundai.

This hook was printed on a RepRap machine

Away from the fashion world, 3D printing has many applications for the developing world.

The ability to produce specially designed objects from a computer offers exciting possibilities for making vital tools in poorer, hard to reach areas.

One scheme that is looking to capitalise in the technology is RepRap, short for Replicating Rapid Prototyping, which offers a cheap way of replicating objects - including the printer itself.

"It's a 3D printer that prints out a kit of parts for another 3D printer," explained Dr Adrian Bowyer from the University of Bath.

"It doesn't print every last single part. There are some which, at the moment, are a little bit difficult for the machine to manage - so things like electric motors and the electronics circuitry the machine can't do for itself - but it prints out a lot of the rest."

Technological disruption

In contrast to early 3-D printing machines which cost around £20,000, Dr Bowyer says a RepRap machine comes in at just £300.

And the software and hardware specifications are all open source - meaning the machine can be duplicated freely.

This low barrier to entry has piqued the interest of many entrepreneurs, keen to see how the technology can be effectively deployed.

David Flanders, a technology enthusiast and blogger based in London, has been experimenting with ways to do good with the RepRap machine.

"Imagine I print you a shoe. Your child grows, as they do. You take that shoe, you throw it back in the shredder - the shredder then processes the plastic.

"You scale up your design 0.3% and you've got your child's next shoe. That's the type of imaginative excitement that we really are talking about."

In the past, the ability to print, burn CDs or DVDs have been seen as a serious threat to intellectual property, making the act of piracy easier.

3D printing is no different. Public Knowledge, a Washington-based public interest group "working to defend citizens' rights in the emerging digital culture" referred to the advancements as the "next great technological disruption".

In a paper entitled "It will be awesome if they don't screw it up", external, Michael Weinberg wrote: "The ability to reproduce physical objects in small workshops and at home is potentially just as revolutionary as the ability to summon information from any source onto a computer screen."

He is now calling on 3D printing entrepreneurs to remain vigilant of policy debates attempts as the technology develops into the mainstream.