CES 2016: Desktop 3D printer uses paper, glue and razors

- Published

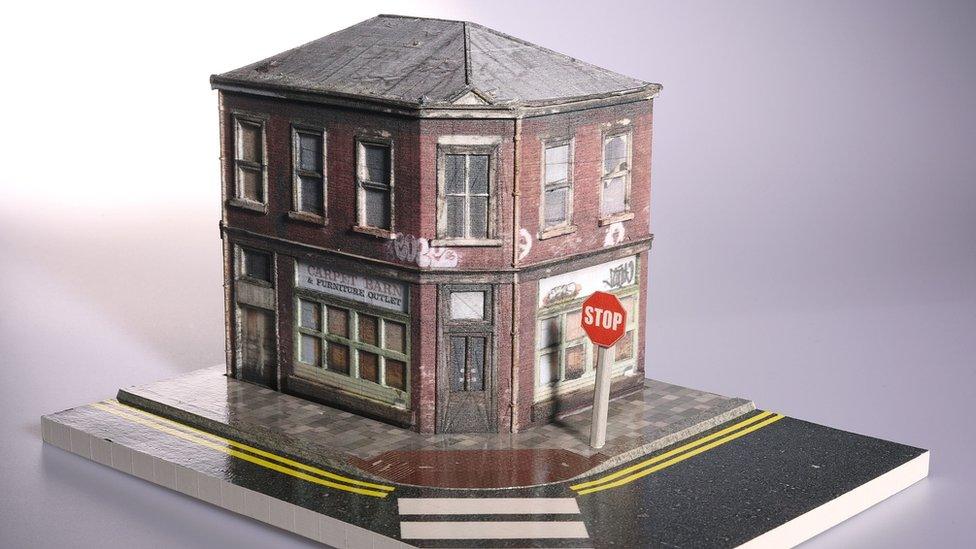

Mcor's printer uses normal office paper to create 3D objects

A desktop 3D printer that uses paper, ink and glue to create highly detailed objects has been unveiled at the CES tech show in Las Vegas.

Mcor said it was the first time such technology had become available in a machine suitable for classrooms and offices.

The device is one of many new 3D printers to have been announced.

Other launches include a sub-£200 ($300) model and a machine that creates circuit boards.

The Mcor Arke can make highly detailed models out of paper

There is still uncertainty about the sector as a whole. Share prices in many of the firms involved sank in 2015 over concerns the industry had been over-hyped.

But shipments are still forecast to rise from about 244,000 devices in 2015 to 2.4 million units in 2018, according to research firm Gartner.

Razor cuts

The Mcor Arke creates colour models at a resolution of 4,800 by 2,400 dots per inch, providing higher detail than many 2D printers.

It does this by using razors to cut plain paper into shape, inkjets to colour it and then glue to join all the layers together and to laminate the final object.

The firm believes its use of normal paper gives it an edge over rivals.

Mcor says it has already received pre-orders for more than 2,500 units of the new printer

"Because paper is used with other non-toxic materials, no special ventilation or disposal systems are needed, just an ordinary recycle bin [and none of] the messy powders or melting plastics used by other 3D printers," it said.

The machine - which is targeted at schools and offices - is due to go on sale before July and will cost $5,995. That is about half the price that Mcor had been charging for a much bulkier model.

"Nobody can match Mcor's resolution in terms of colour," said Daniel O'Connor from TCT magazine.

"This printer's resolution is twice that of any industrial machine, and those industrial machines typically cost over $50,000."

Cutting costs

Taiwan's XYZprinting is hoping to succeed by selling a model for just $269.

The Da Vinci Mini is XYZprinting's cheapest model to date

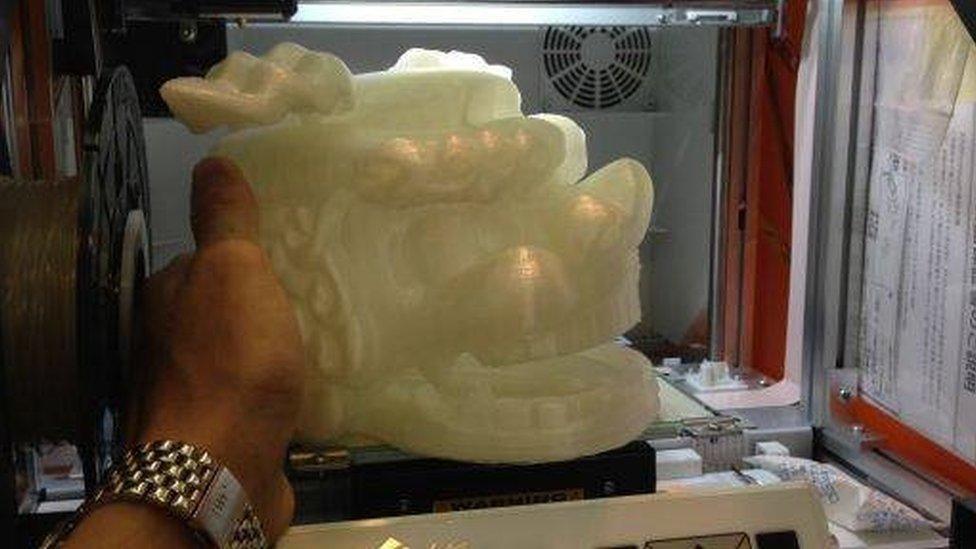

The Da Vinci Mini makes objects by squirting hot plastic to build them up layer by layer, a basic technique that means creations can look a bit rough and ready.

But the company suggests it could serve as a starter device.

"Making 3D printing technology affordable and accessible has always been XYZprinting's biggest goal so that we can break down the barriers to ownership," the firm's chief executive Simon Shen told the BBC.

"There are other obstacles apart from price, such as speed and multiple colours, but it's just a matter of time [before] every home and office has at least one 3D printer."

The Da Vinci Mini can create objects up to the size of 5.9in (15cm) cubed

Mr O'Connor said it was significant that an established brand was now offering a 3D printer for less than a games console.

"The machines XYZprinting are producing may not be the highest quality in the world, but they more than fill the void for what people want for schools and other educational purposes," he said.

Titanium prints

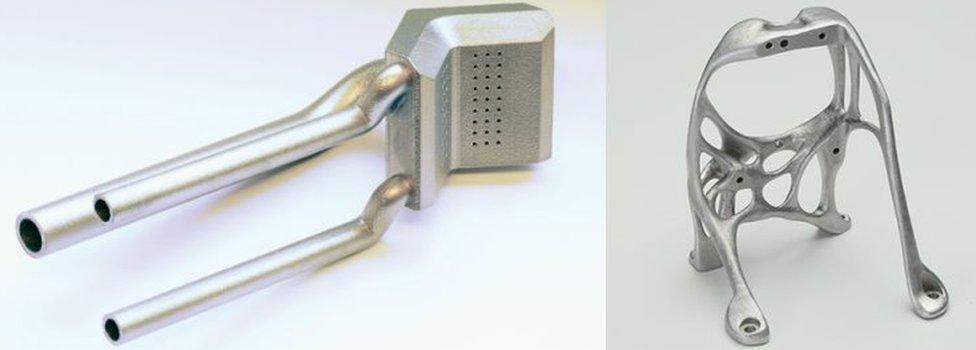

3D System's new printer can make objects out of metal that would be otherwise difficult to construct

There is also much higher-end gear at CES.

3D Systems has a model that can print complex objects out of titanium, stainless steel and nickel.

The ProX DMP 320 is targeted at the aerospace and automotive industries and costs up to $700,000.

The Dragonfly 2020 can print multilayer circuit boards to help test if the designs work

Nano Dimension, an Israeli start-up, is demoing a printer that uses inks containing nanoparticles of silver to create complex circuit boards.

It says the Dragonfly 2020 can help gadget-makers bring products to market more quickly by making it easier to test the electronics involved.

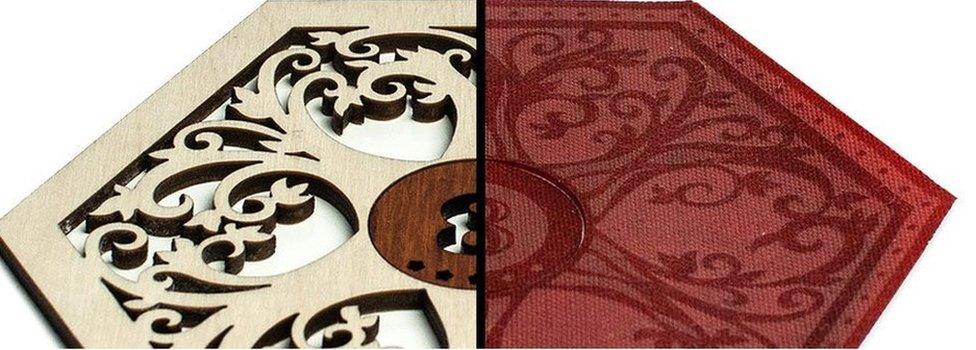

The Glowforge can handle wood and fabrics

Other exhibitors include:

Glowforge, which has a printer that uses a laser that can both cut and engrave wood, leather, fabrics and acrylic

Voxel8, which has developed a 3D printer that adds pre-made electronic parts and wiring to objects as it creates them

Polaroid, which has revealed a 3D printer with a built-in camera that transmits photos via wi-fi, so owners can monitor progress from afar

Polaroid's 3D printer contains a wi-fi enabled camera

Winning back trust

Makerbot - one of the biggest 3D printing brands - is also in attendance.

Its latest product, the Smart Extruder+, may not seem as eye-catching as those of its rivals, but it marks an important moment for the business.

The $199 device allows users to upgrade the part of their machine that melts plastic and pushes it through a nozzle to build up an object.

Makerbot says that its updated version of the Smart Extruder will be reliable

It includes a sensor that can pause the printing process if it detects the plastic has got jammed or run out, and sends an alert to its user's smartphone.

The component is itself a replacement for an original version, launched in 2014, which customers complained had a tendency to fail sooner than expected.

Last year, a class action lawsuit was filed over the matter that claimed the firm had knowingly sold a product it knew had problems.

Affected owners were particularly annoyed that Makerbot had only offered a 90-day warranty for the device. That has been extended to six months for the Smart Extruder+.

"Makerbot had pretty bad publicity over the original one," said Mr O'Connor.

"It really needs to focus now on improving its technology and making it work rather than launching fancy new machines, and I think that's what it is doing now."

Read more of our CES articles and follow the BBC team covering the show on Twitter, external.

- Published6 January 2016

- Published6 January 2016

- Published6 January 2016