Shopping robots on the march in Ocado

- Published

The Ocado warehouse run by robots

There is growing concern about the impact of automation on employment - or in crude terms - the threat that robots will eat our jobs.

But if you want to see how important robotics and artificial intelligence can be to a business Ocado is a good place to start.

"Without it we simply couldn't do what we do at this scale," the online retailer's chief technology officer Paul Clarke told me. With margins in the supermarket business wafer thin, continually bearing down on costs and waste has been vital.

At its Hatfield distribution centre I got a glimpse of how far the process of automating the sorting of thousands of grocery orders has come. For now, you will struggle to spot a robot - unless you count a machine that inserts plastic shopping bags into crates - but software is doing a very complex job of sending the right goods in the right crates to the right human pickers.

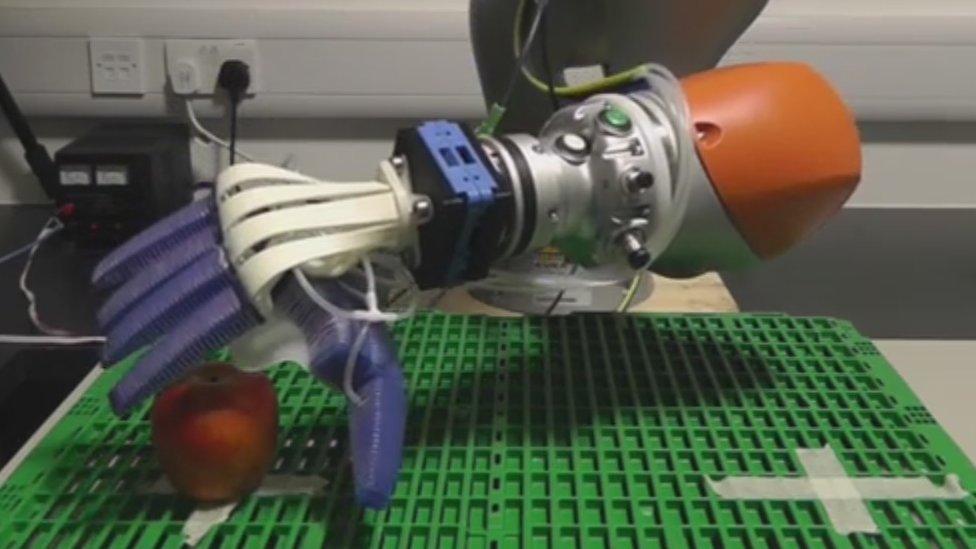

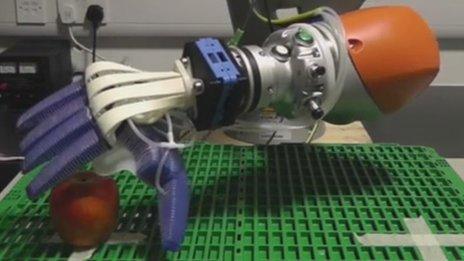

Roboticists at Ocado are working on a robotic hand, gentle enough to pick up fruit

"This warehouse is crammed with machine learning and algorithms that are controlling all manner of operations that are invisible to the human eye," Mr Clarke explains.

But in one corner of the warehouse is the robotics lab where the next stage of automating Ocado is under way. A group of some of the smartest robotic engineers from across Europe are at work on their latest project which could replace human pickers one day. It's a robotic hand sensitive enough to pick up a piece of fruit without damaging it.

"The overall challenge is to develop robotic systems that can pick and pack the full range of items," explains head of robotics Alex Harvey.

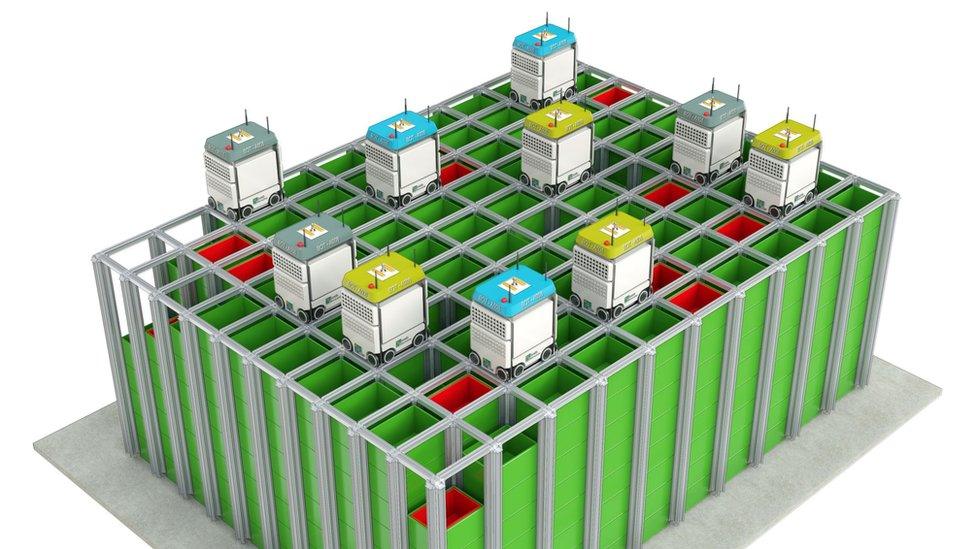

The robot warehouse contains crates containing various goods which the robots select

The robot hand won't be ready to start work for a while but at Ocado's newest warehouse in Andover, Hampshire, a robotics project that the company believes is unequalled in its sophistication has already been deployed. Swarms of robots move across a grid, collaborating with each other to collect groceries stored beneath them and then bring them to a human picker.

Showing me some video of the warehouse, Paul Clarke explains the technical challenge: "Controlling thousands of robots in real time has required not only building a very sophisticated AI-based air traffic control system but also we've had to evolve a new communications systems to talk to all those robots 10 times a second."

But seeing all those swarming robots with not a human in sight sparks an obvious thought - what about the impact on jobs?

Ocado says despite the onward march of automation its workforce has continued to grow. "We have no choice both as a company and as UK PLC but to invest in this technology," says Mr Clarke."We are a net employer of 12,000 people, none of whom would have a job at all if it weren't for our use of automation because this has been our differentiator as a business."

Economists disagree on the scale of the threat to employment. An Oxford study which predicted that more than 40% of occupations could be threatened by automation over the next two decades is now seen by many as far too pessimistic.

Will human jobs change as robots take on some of the roles we currently fill?

That is certainly the view of Laura Gardiner, of the Resolution Foundation, who points out that jobs are becoming more multi-faceted, so that even if one task is taken by a robot, there will still be others left for the humans.

But she does accept that for certain categories of worker life may get harder: "It is right to be concerned about specific occupations - secretarial work, processing jobs in factories - moderately skilled jobs which used to pay quite well."

What is clear is that in an evolving job market, some skills will become redundant, while others will be in higher demand. And the best advice? Train as a robotics engineer.

- Published31 January 2017

- Published5 January 2017

- Published14 September 2015