Fruit-shaped sensor 'can improve freshness'

- Published

A new fruit-shaped sensor could help cargo companies to keep fruit fresher in transit, researchers say.

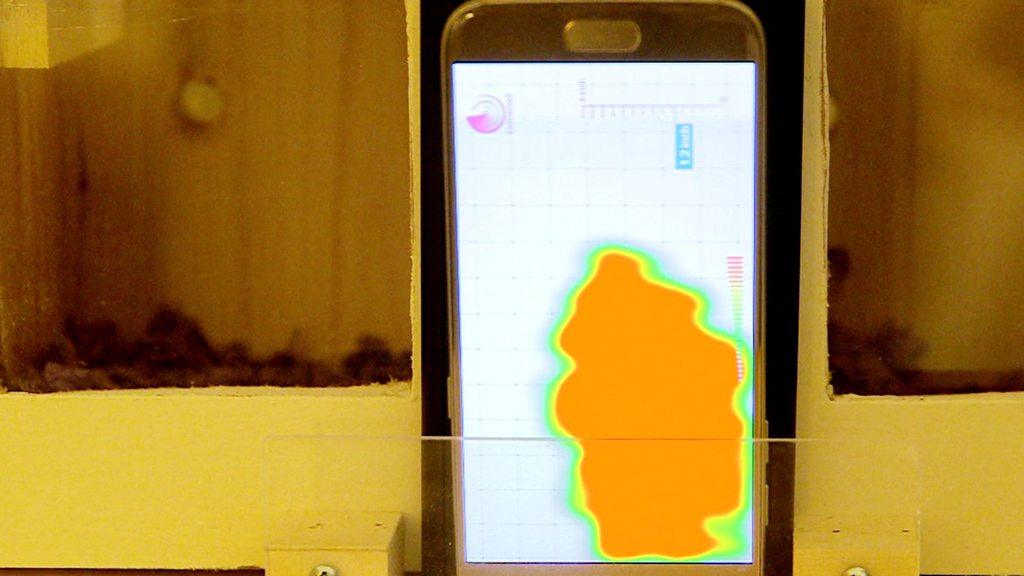

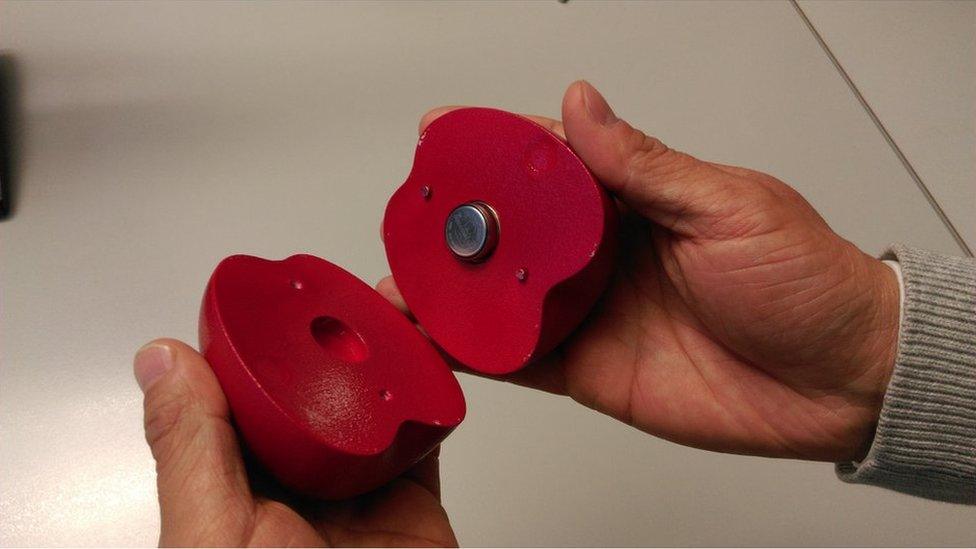

The device - which mimics the size, shape and composition of real fruit - is packed in with produce in transit and closely monitors its temperature.

It comes in orange, apple, banana and mango varieties, and alerts firms to problems with their cooling processes, allowing them to take action.

It could also lead to fresher fruit for consumers, researchers said.

The project, which is still at the trial stage, is being conducted by the Swiss Federal Laboratories for Materials Science and Technology (Empa).

Communications spokeswoman Cornelia Zogg explained, external: "Mangos, bananas and oranges have usually travelled long distances by the time they reach our shops.

The sensors are packed in with real fruit in cargo holds

"However, not all the cargo makes it safely to its destination.

"Although fruit is inspected regularly, some of it is damaged or may even perish during the journey. This is because monitoring still has significant scope for improvement."

Fruit destroyed

The researchers say this creates risks for both suppliers and consumers.

State food agencies can order container loads of fruit to be destroyed if it hasn't been stored at the right temperatures.

And fruit which is overripe or not fresh can end up being sold to consumers.

"Cargo could be left outside during a layover, or you could have a power outage during transit, all of which affects quality," project leader Thijs Defraeye told the BBC.

"Exporters do have ways to measure freshness, but our sensor is more accurate because it simulates the characteristics of individual types of fruit."

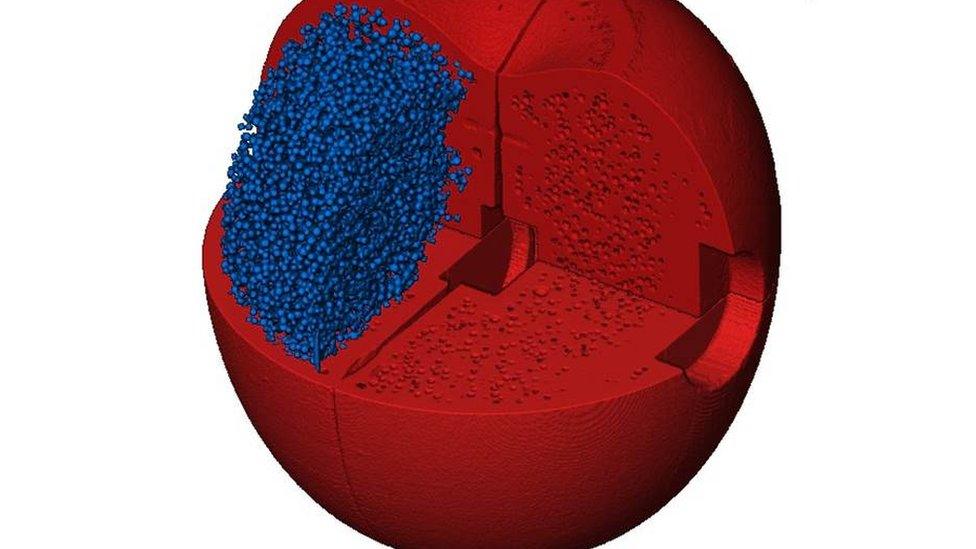

The fruit's composition is modelled using computers.

To achieve this, the team X-rayed real fruits and modelled their shape and texture, he says.

They then determined the exact composition of each fruit's flesh and simulated it in a laboratory, using a mixture of water, carbohydrates and polystyrene.

The mixture was poured into a fruit-shaped sensor mould, created on a 3D printer.

Mr Defraeye said: "If something goes wrong, suppliers will be able to access the temperature data from the whole journey and work out what happened.

"We hope this will help them control their sanitary protocols and cut the cost and time of logistics."

Field tests for the sensors are under way and the researchers are looking for potential commercial partners.

- Published22 February 2017

- Published21 February 2017

- Published17 January 2017