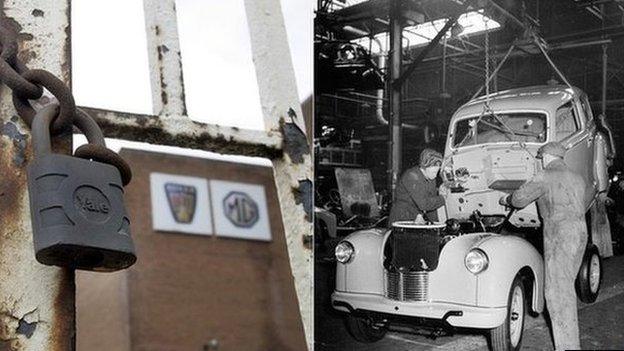

MG Rover: Birmingham recovering 10 years after mass car production ended?

- Published

The news of the end of mass car production at the Longbridge works in Birmingham was described as "devastating" back in April 2005. But 10 years on, have the dire predictions about the effect of the plant's closure on the city's economy proved true or false?

"The darkest day in the history of the British car industry" was how Tony Woodley, from the Transport and General Workers Union described the closure of Longbridge, with the loss of 6,000 jobs.

John Edwards, the chief executive of Advantage West Midlands, a regional development agency which has itself since been scrapped, called the closure "disastrous".

And the gloom spread beyond the borders of Birmingham, along the supply chain of companies making components for the fallen plant of car giant MG Rover.

Chris Harvey, from the Chamber of Commerce in neighbouring Worcestershire, predicted the closure would have "a major impact on firms".

A worker's story

Longbridge workers march to try and save their jobs before the plant eventually shut

Spencer Hampton was one of those 6,000 workers who lost their jobs - it is a day he has never forgotten.

"I can remember April 8th because it was my wife's birthday, and it was the day my world fell in," he said.

"I'd been there 14 years and it was a job for life I signed up for - my whole life revolved around MG Rover, my work my pension."

A former team leader at MG Rover, his worst memory is of being "herded into the dole office, feeling about two inches tall".

Ten years on, retrained and working in the NHS, he is more philosophical.

"If you'd told me when it was happening to just bear with it, good is going to come out of it, I'd have probably said a few choice words.

"But looking back it's the best thing that happened - my regret is it didn't happen sooner."

Employment downturn

The impact could be seen immediately in the unemployment figures for Longbridge and Northfield wards, the closest areas to the plant, and for the city as a whole.

But 10 years on, unemployment is back to pre-closure levels, according to city council figures.

John Bryson, professor of enterprise and competitiveness at the University of Birmingham business school, said that in hindsight the closure was "quite good for the city" as it spared MG Rover from "death by a thousand cuts".

A decade on, he says the West Midlands is the only part of the UK that has a trading surplus with China.

"A lot of manufacturing is now knowledge based, so if you go into some of these companies they look more like service companies than old-fashioned 19th Century dirty, oily manufacturing shop floors," he said.

He points to the success of car firms including Jaguar Land Rover (JLR), and smaller companies like Morgan in Malvern, Worcestershire.

"Compare the last two or three years of [Longbridge] with JLR over the last few years you see a very different story - about half of the Chinese export growth comes down to JLR and its supply chain," Prof Bryson said.

"There is always the danger that JLR switches more of its production to China as its market moves away from Europe and the USA, but it's still going to have a significant UK operation because it has invested in plant, it has invested in skills, it has invested in a better West Midlands-based economy."

The rise of Jaguar Land Rover

6,000 people work at the JLR plant in Solihull

Jaguar Land Rover profits more than doubled in the last three months of 2013 to £842m

Workforce has grown from 16,304 in 2010 to 24,913 in 2013

Solihull plant making Land Rovers employs 6,000 on a 300 acre site

A new engine plant will open this year on the i54 industrial estate in South Staffordshire

£2bn invested in West Midlands manufacturing plants in the last five years

More than 80% of output is exported - 23% to China, 20% to Europe and 17% to North America

JLR and its Chinese partner Chery Automobile opened a £1bn manufacturing plant opened at Changshu, China in 2014

The unions put the emergence of the automotive industry from its "darkest day" down to the changing relationship between workers and management.

Car workers were the seen as villains in the days when there were 523 disputes at British Leyland (BL) in a single year in the late 1970s.

However Tony Burke, of Unite, believes they are now the "unsung heroes" in the post-Longbridge revival, which has seen companies like JLR, Nissan, Toyota and BMW put "real faith in the UK workforce".

He believes they have shaken off the "bad press" from what was happening at BL.

"From our members there was a recognition that if these factories closed there would be no jobs for the future - there was compromise, but our members gave up one hell of a lot," he said.

"Now we have a highly skilled workforce who, in the depths of the recession, helped the industry survive by making agreements that increased competitiveness."

Workers' pride in their jobs has helped make the whole city feel more positive, Prof Bryson believes.

"[If] you are working for a big global company which is highly visible within the media - it's exciting."

After the closure

The plant once covered 400 acres

Car manufacturing began in 1906

At its biggest, the plant covered 400 acres - the pitch at Villa Park would have fitted into it 227 times

A total of 27,000 people were employed at its non-wartime peak, more than the population of Stratford-upon-Avon

In 1967/68 production peaked at 348,664 vehicles

Between 1978 and 1979 there were 523 disputes at British Leyland

The plant produced more than 14m cars

Mini Metro production line at Longbridge

Longbridge loomed large in the wider perception of Birmingham as a city - a place of industrial strife when open, a vast empty wasteland when the plant was demolished.

The Chamber of Commerce believe the city has "re-invented itself since the dark days of Longbridge".

"The city has transformed itself into a major retail centre, starting with the Bullring, and more recently Grand Central - plus we have the prospect of the Curzon Street station development coming with the HS2 rail line.

"Birmingham has also become a draw for high tech companies, banking - and you have the success of JLR," a spokesman said.

The city has become a "more liveable and exciting place", according to Wouter Schuitemaker, from Marketing Birmingham.

He believes this explains the more than £1bn of inward investment last year - "the majority of it from 77 foreign firms".

Longbridge redevelopment

Site of the Longbridge plant after its demolition

50 firms employing 400 people at a new technology park

New three acre Austin Park opened in September 2013

30,000 sq ft (2,800 sq m) Bournville College Construction Centre completed in September 2014

165,000 sq ft (15,330 sq m) of retail space opened, with another 150,000 sq ft (14,000 sq m) planned

2,000 new homes planned

Source: St Modwen Developments

New development has included Bourneville College, which re-located to Longbridge Lane

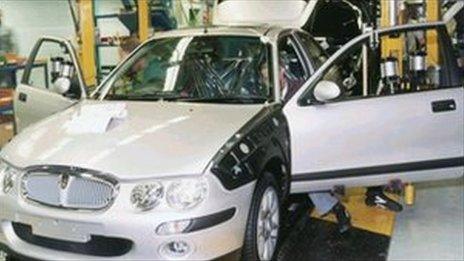

And the giant Longbridge works may be no more, but the MG marque has survived the turmoil of 10 years ago.

The MG brand was bought by SAIC, China's largest vehicle manufacturer.

It has a 60-acre site in Longbridge employing about 400 people. Cars are painted and part assembled in China, with the power train, suspension and final assembly taking place Birmingham.

The changing face of Birmingham

Selfridges in the Bull Ring, Birmingham

£500m redevelopment of the Bull Ring area, which finished in 2003

£600m revamp of New Street station and the Grand Central shopping complex, opening later this year

350 acres (141 hectares) around the Curzon station site to be redeveloped as a terminus for the HS2 high speed rail line

Artist's impression of the planned redevelopment around Curzon Street station

- Published8 April 2015

- Published23 October 2014

- Published28 July 2013

- Published28 August 2013

- Published18 January 2012

- Published7 February 2011

- Published13 April 2011

- Published13 April 2011

- Published21 September 2010