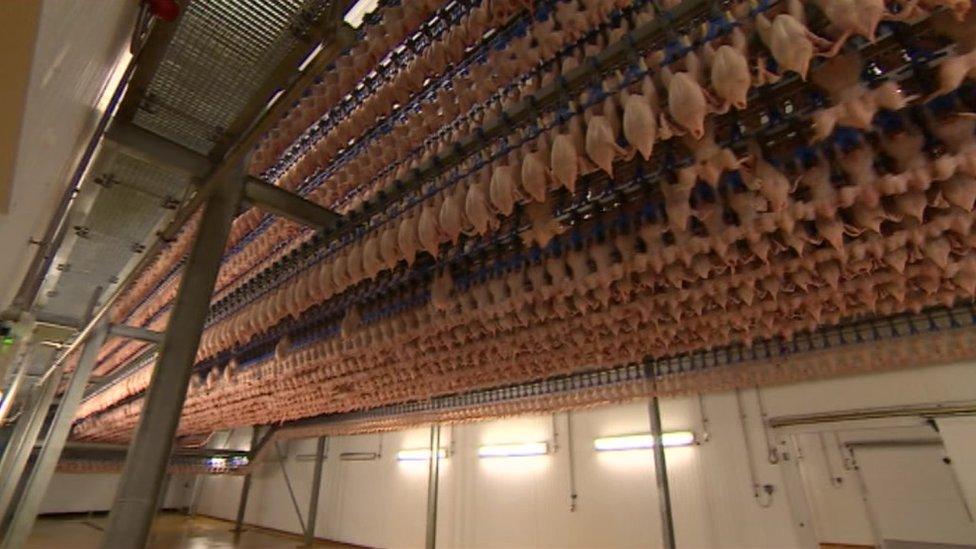

Inside a major chicken processing plant

- Published

- comments

The plant is one of the largest in the UK

I've been trying to film at the Cargill poultry plant in Hereford ever since I arrived in this job, which is more years than I care to remember.

When it comes to agriculture in the Midlands the poultry business is the second most valuable slice of our farming pie. It's behind dairy at number one but at £207m it's worth more than wheat, cattle or fruit.

The Cargill plant is a huge part of that story.

But most of us don't like to think too closely about where our chicken, lamb or beef actually comes from and perhaps not surprisingly the companies that produce it recognised that fact. They don't tend to go about shouting too loudly about what they do.

So I was pleasantly surprised that this time they said "yes" to us filming.

The chickens are killed through a process called gas stunning. The live chickens move through a deep pit filled with increasing concentrations of carbon dioxide. First they go to sleep, then they suffocate.

And they allowed us in at a very interesting time for the company. There's a revamped multi-million pound production line, a new boss just arrived from Kansas in America and some difficult questions for the poultry industry in general about the infection rates of a nasty food poisoning bug.

Cargill has much to be proud about. It's a Midlands success story with a huge plant (which a long time ago used to be branded as "Sun Valley") in the middle of a £35m expansion programme, employing more than 2,000 people. In uncertain times rearing chicken is a good option for farmers near the plant looking to diversify. For consumers affordable, good quality chicken is a very popular choice.

There are problems for the poultry industry however. Not least a food poisoning bug called campylobacter which is the main cause of food poisoning in the UK. A report , externalearlier this year from the Food Standards Agency (FSA) found this bug on almost three quarters, external of all supermarket chickens. One expert called it a "national disgrace", external.

Campylobacter is 'serious'

Campylobacter is certainly serious. It is also common and found all over the place which means it's easy to pick up but hard for companies like Cargill to get rid of. Since the FSA report was published the entire industry, external has been looking hard at what it can do to reduce the levels in our raw chicken.

About 1.6m chickens a week pass through the Hereford plant. That's 26,000 per hour.

Initially that's meant concentrating on the farm end of things and improving staff training and procedures.

But companies like Cargill have also been working on introducing new technology to the chicken production line. Killing campylobacter is actually really simple, it can't survive extreme heat or cold. But the tricky bit is blasting freshly butchered meat with very hot steam or an icy blast and making sure you don't damage the meat in the process. Chicken that's safe but has the consistency of leather boots is no use to anyone.

Cargill is now installing newly developed technology that will use steam and ultrasound to kill any lurking bacteria while preserving the quality of the meat. They showed us the space in the production line where the machine will go. But even before it starts work they say they have already managed to achieve a reduction in campylobacter rates. The Food Standards Agency will shortly start a new survey to see how the whole industry is doing.

Plan for growth

The big question for me as a reporter and fan of eating chicken was how would I feel when I went to see the slaughter process? This is an important part of my job as rural affairs correspondent and I have visited several slaughter houses. Here they use a process called gas stunning. The live chickens move through a deep pit filled with increasing concentrations of carbon dioxide. First they go to sleep, then they suffocate. The whole process is monitored by staff and a government vet.

Cargill is installing newly developed technology that will use steam and ultrasound to kill any lurking bacteria

Cargill call this a world class facility and processes like gas stunning could well be exported to the rest of the group across the world. It compares very favourably to other older methods of large-scale chicken slaughter which involve live birds being hung up by their feet and dipped head-first into an electrified bath of water.

So what are the thoughts of the new boss Mary Thompson? Freshly arrived from Kansas she was very clear when I asked her what the plan for the whole site was.

"Growth" she said.

And for the staff and farmers who work with Cargill that's good news.