Coronavirus: University of Hull plans 20,000 face shields a week

- Published

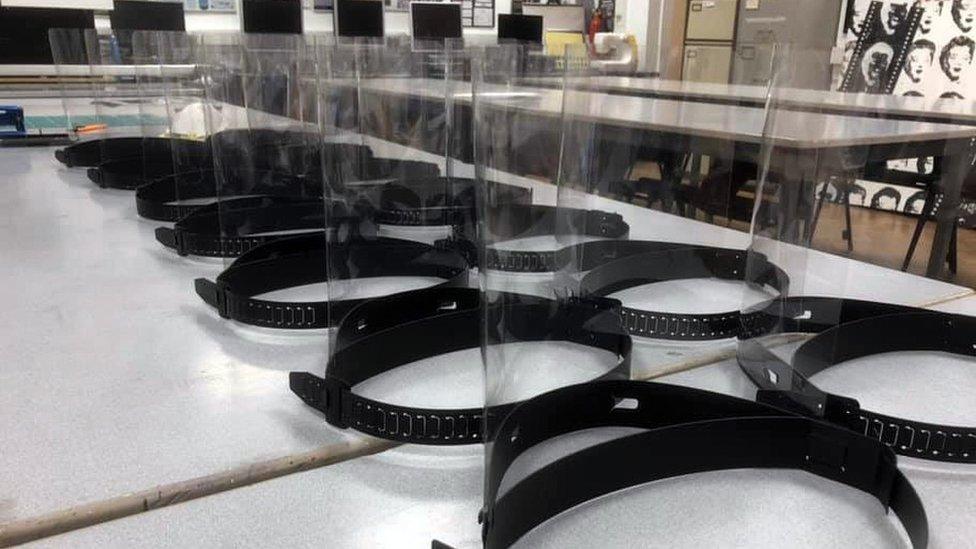

The designs mean more face shields can be produced at a faster rate than using 3D printing

A university has announced plans to produce more than 20,000 face shields a week for healthcare workers.

A team of engineers at the University of Hull have created new designs which can be produced using laser cutting and injection moulding.

They said the techniques were better suited to high-volume production than 3D printing.

The university is leading a collaboration to increase production of face shields for NHS workers.

The engineering team adapted designs to suit their 3D printers after a request from NHS consultant, and they delivered around 500 shields in four days.

They then looked into how they could scale-up production.

"3D printing is very good for making one-off parts but when you're looking for mass production, it's not really the technology that we want to be using," Nathan Brown, senior lecturer in mechanical engineering, said.

The university is now working with a local injection moulding company, who have adapted the 3D design to suit their manufacturing process.

Louise France, from the University of Hull, inspects a 3D-printer faceguard

"Hopefully, within the next week or so, we should be in a position from that design that we can manufacture between 2,000 and 5,000 a day," Mr Brown said.

He added the team had developed another design based around technology, such as laser cutting, water jet cutting or stamping, to produce the product, which would also enable large numbers to be manufactured.

Mr Brown said the designs would be shared nationally to enable production in other regions.

A SIMPLE GUIDE: How do I protect myself?

AVOIDING CONTACT: The rules on self-isolation and exercise

LOOK-UP TOOL: Check cases in your area

MAPS AND CHARTS: Visual guide to the outbreak

VIDEO: The 20-second hand wash

Follow BBC Yorkshire on Facebook, external, Twitter, external and Instagram, external. Send your story ideas to yorkslincs.news@bbc.co.uk, external.

- Published7 April 2020