Tiny loom harks back to Leeds dominance in textile industry

- Published

Made in 1945, the tiny model was once a fully working machine

A miniature replica of the large weaving machines which dominated Yorkshire's textile industry has been conserved for museum visitors.

The scale model, less than 20 inches (50cm) high, recreates in tiny detail the looms once manufactured by local firms.

Made in 1945, it was once a fully working machine and even has a half-finished green handkerchief inside.

It has undergone delicate cleaning at the Leeds Industrial Museum.

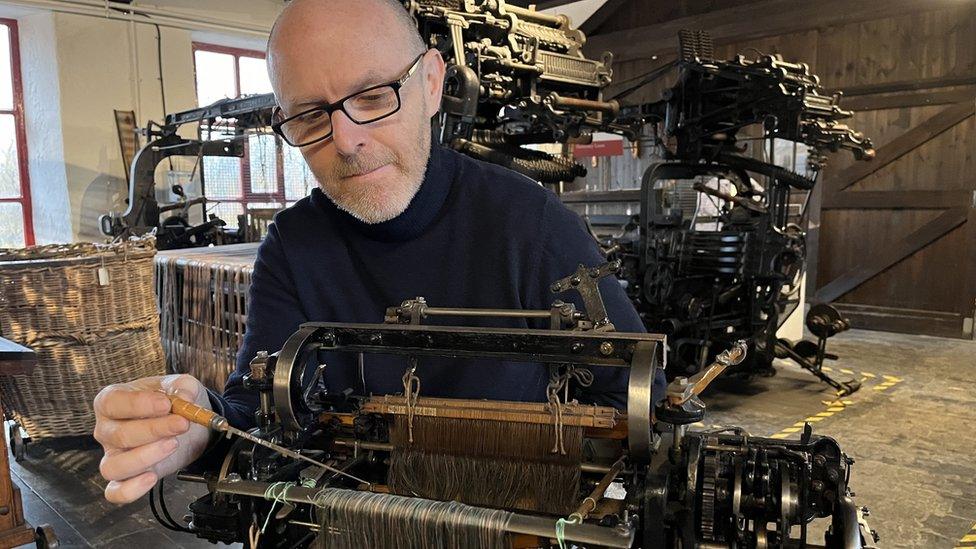

It stands in the shadow of its full-sized counterpart at Leeds Industrial Museum

Work on conserving the machine, which is 31 inches (80cm) wide, stands in contrast to its larger counterpart- the full-size Hattersley standard loom, which measures more than 6 ft 5 inches (2m) high.

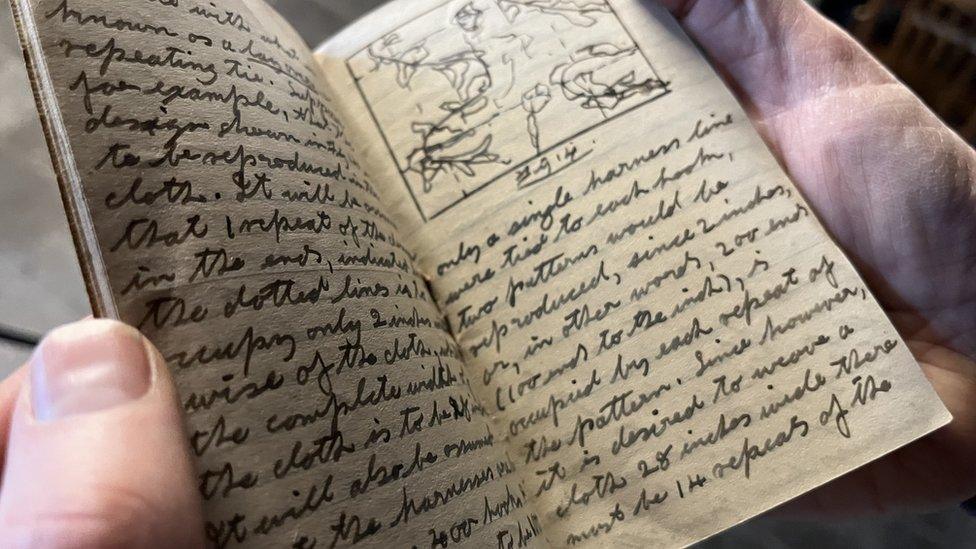

It comes complete with tiny versions of the tools and accessories used in the larger version and a hand-written instruction manual penned by its original maker.

John McGoldrick, Leeds Museums and Galleries' curator of industrial history, said: "It's a case of little meets large.

"This is a really small, precise model and was probably made with the same kind of skill levels of watch and clock makers.

"In fact, clock makers were often called in to make models for these early textile and industrial machines because they were the only people who had the skills at the time."

Themachine comes complete with tiny tools and instruction book written by the maker

Mr McGoldrick said the smaller loom would have been "very expensive" to make and would have been used as a demonstration model when manufacturers were showcasing the larger looms to sell to the mills.

The curator said preserving the machine had to be done carefully to protect all the different materials.

"You've got steel, you've got iron, you've got brass leather textile, so you have to find the right balance of temperature and humidity, so each kind of material is happy.

"You can never completely stop things deteriorating but you can slow it down."

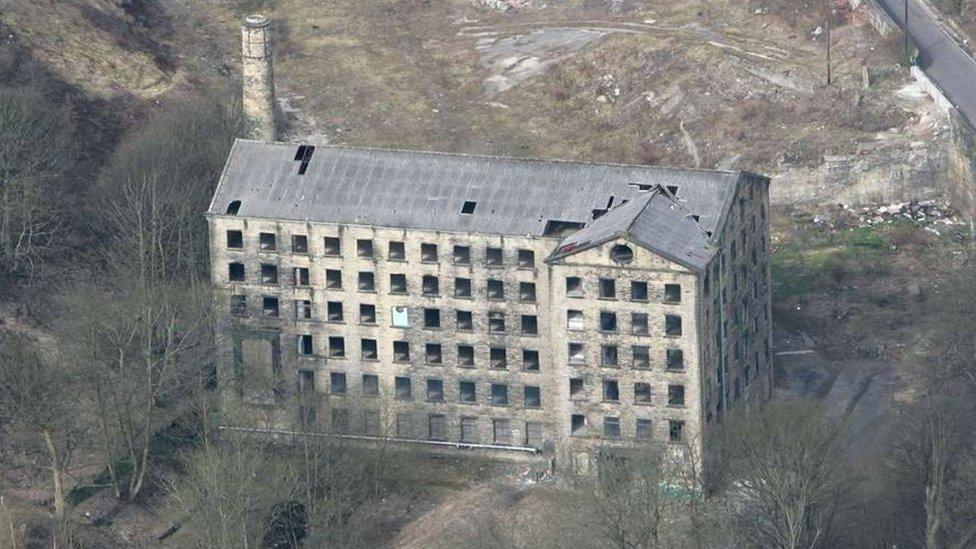

The larger looms also on display at the museum, itself one of the world's largest woollen mills in the world, were made by George Hattersley and Sons Ltd. of Keighley.

The firm made every type of loom until its closure in 1981 and each of those it produced was painstakingly packed in specific order to ensure all the parts worked properly.

Their "booming presence" in Yorkshire mills was a sight to behold, said Mr McGoldrick.

"Not only the size of them, but the sound was absolutely deafening.

"There were a lot of people who had their hearing damaged as a result of working for long periods in the mills.

"Workers formed their own kinds of communication while operating the machines, almost like lip reading so they could understand each other over the dim of the working machinery."

Follow BBC Yorkshire on Facebook, external, Twitter, external and Instagram, external. Send your story ideas to yorkslincs.news@bbc.co.uk or send video here

Related topics

- Published26 September 2023

- Published20 November 2017

- Published30 June 2016