Challenge of Redcar blast furnace relighting

- Published

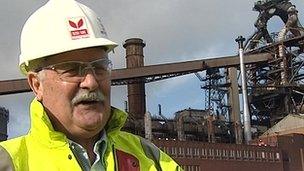

Dave Johnson has worked in the steel industry since 1978

Two of the men who have been involved in relighting the blast furnace at the former Corus steelworks on Teesside have spoken of the "privilege" of taking part.

Dave Johnson and Derek Thomas have between them more than 80 years' experience in the steel industry.

Both spoke about the huge achievement of reopening the Redcar steelworks, which is now owned by Thai-based SSI, two years after it was mothballed.

Mr Johnson is the general manager ironmaking, which essentially means he is in charge of the blast furnace. He started in the industry in 1978 and working on blast furnaces in 1992.

He said "Two years ago was genuinely one of the saddest days of my life."

'Exciting process'

He was in charge of the night shift when the furnace was blown out.

"I thought that was it. I sat in the car park and cried," he said.

Mr Johnson said he did not think the site would reopen, but was delighted to be invited back when it was announced that it would.

He said the process had been "immensely exciting" but also a huge challenge which has seen him working up to 14-hour days.

There has been a major recruitment process and the workforce will be made up of a mixture of experienced workers and those who are new to the industry.

But he said he had been able to spread the skill base sufficiently.

He said restarting the plant had been a major project.

"To close down completely, get rid of a workforce and then bring it back to life. That's a massive statement," he said.

He said the level of interest on Teesside had been "fantastic" and he was "privileged" to be part of it.

"There is something about blast furnaces. It gets into your soul if you like. I am passionate about it. I am looking forward to being part of its resurrection," he said.

'Real challenge'

In September, Mr Thomas, who is director for the restart project, will mark 50 years in the steel industry, having retired twice.

He viewed the relighting as a "truly historic event".

Derek Thomas is director of the furnace restart project

He said it was hard work and demanding but had been a real achievement.

Mr Thomas said the process started in May or June last year and they had achieved in months what might usually take several years.

He said it had meant they had had to hit the ground running and learn as they went along.

"To accomplish this in something like nine months is a fantastic achievement," he said.

He said among the challenges had been the amount of debris in the pipes after being unused for two years.

He described the blast furnace as the "heart of the plant".

He said: "It's never been done at this scale and this speed. That's the real challenge."

- Published23 October 2011

- Published12 August 2011

- Published9 August 2011

- Published7 August 2011

- Published23 June 2011

- Published25 March 2011

- Published27 May 2010