Scientists produce 'world's smallest Christmas card'

- Published

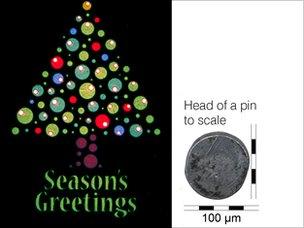

Glasgow University provided this graphic to demonstrate how small the card is

Scientists have produced what they believe is the world's smallest Christmas card.

It was created by nantotechnologists at the University of Glasgow and is so small it could fit on to the surface of a postage stamp 8,276 times.

The image, which measures 200x290 micro-metres, features a Christmas tree and is etched on a tiny piece of glass.

The team behind the project said the technology could eventually be used in products such as TVs and cameras.

The university's school of engineering drew up the design to highlight its "world-leading" nanotechnology expertise.

Prof David Cumming said: "Our nanotechnology is among the best in the world but sometimes explaining to the public what the technology is capable of can be a bit tricky.

"We decided that producing this Christmas card was a simple way to show just how accurate our technology is.

"The process to manufacture the card only took 30 minutes. It was very straightforward to produce as the process is highly repeatable - the design of the card took far longer than the production.

Human hair

Prof Cumming added: "The card is 200 micro-metres wide by 290 micro-metres tall.

"To put that into some sort of perspective, a micro-metre is a millionth of a metre; the width of a human hair is about 100 micro-metres.

"You could fit over half a million of them on to a standard A5 Christmas card - but signing them would prove to be a bit of a challenge."

The colours were produced by a process known as plasmon resonance in a patterned aluminium film made in the university's James Watt Nanofabrication Centre.

Although the Christmas card example is a simple demonstration, the university said the underlying technology had important real-world applications.

The electronics industry is taking advantage of micro and nano-fabrication technology by using it in bio-technology sensing, optical filtering and light control components.

The applications are critical in the future development of the digital economy and could eventually find their way into cameras, television and computer screens to reduce the manufacturing cost.