Distilleries win funding to cut carbon emissions

- Published

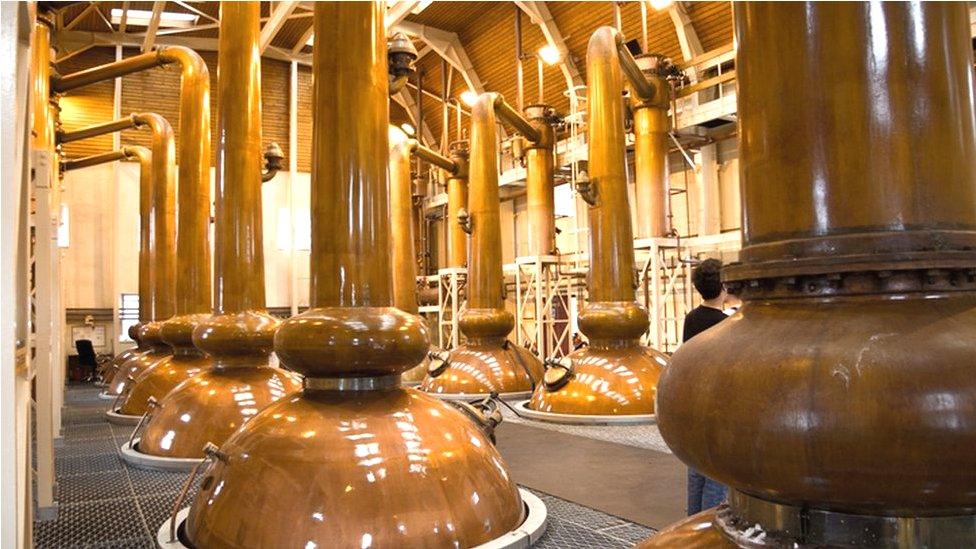

Seventeen projects are to benefit from the first phase of a £10m UK government funding package to help decarbonise distilleries.

Eleven sites in Scotland will receive research and development money for schemes such as hydrogen power.

The other six are based south of the border.

The schemes include a hydrogen burner in South Uist, a high temperature heat store at a site in Aberdeen and a hot water recovery system in Glasgow.

The successful distilleries will receive between £44,000 and £75,000 in the first phase of funding, with schemes including the use of hydrogen and biofuel boilers and geothermal energy in their production processes.

The UK government said the funding would help distilleries cut emissions by almost a million tonnes of CO2 every year - equivalent to taking 200,000 cars off the road.

UK Energy and Clean Growth Minister Kwasi Kwarteng said: "Every business can play a part in the green industrial revolution and this funding will allow UK distilleries to lead the way by making their production cleaner while also creating jobs."

The announcement is part of the UK government's drive to reach net zero emissions by 2050.

List of successful phase 1 distilleries:

Protium Green Solutions (£73,818), lead in London with a distillery partner in Islay: Using a low emission hydrogen boiler.

Locogen (£43,325), Edinburgh: Switching a distillery from fuel oil to hydrogen burners.

Protium Energy (£57,464), Aberdeen: Temperature heat store.

Cornish Geothermal Distillery Company (£75,000), Truro: Creating a geothermal distillery.

European Marine Energy Centre (£58,781), Orkney: Assessing technology pathways to facilitate green hydrogen.

Supercritical Solutions (£53,000), lead in Horsham with a distillery partner in Glasgow: Electrolysers to enable fuel switching to zero emission sources.

Uist Distilling Company (£44,572), South Uist: Combination of a hydrogen burner and indirect heating of a thermal oil rather than steam.

Colorado Construction and Engineering (£73,636.80), Edinburgh: Hydrogen and dual hydrogen/biofuel burners for distilleries.

Vytok (£57,688.00), London: Heat pumps, with water as the working fluid.

Uist Distilling Company (£40,539.23), South Uist: High temperature heat store that would allow a distillery to be run purely on electricity.

John Fergus & Co (£71,812.55), Glenrothes: Use of hydrogen on site to decarbonise process heat.

Edrington Group (£56,930.00), Glasgow: Stillhouse condenser hot water recovery system.

St Andrews Brewers (£51,547.00), Glasgow: Combination of heat pumps, green hydrogen and biomass.

Bennamann (£46,620.11), Cornwall: Use of fugitive methane as fuel.

Sunamp (£61,412.50), Edinburgh: Large-scale phase change material thermal store.

Environmental Resources Management (£68,951.00), London: Liquid organic hydrogen carriers.

Colorado Construction and Engineering (£74,768.10), Edinburgh: Conversion of waste distillery draff and pot ale into a gasification-gas.

- Published29 December 2020

- Published17 November 2020

- Published9 December 2020