Tower train marks end of Welsh coal era at Aberthaw

- Published

The last but one train of coal from Tower Colliery arrives at Aberthaw

There was no ceremony this time but the penultimate train carrying coal from Tower Colliery to Aberthaw arrived bang on time.

The power station in the Vale of Glamorgan has been taking Welsh coal for decades but this 1,450 tonne delivery on Wednesday afternoon was one of the final ones.

Coal used to come from the deep mines of the south Wales valleys until the final underground operation at Tower - re-opened by the miners themselves 13 years earlier - closed down in 2008.

Since then, Aberthaw has relied exclusively on supplies from opencast and drift mines, including Tower Colliery's surface business.

Welsh coal itself is "low volatile" - which means it is harder to burn.

Aberthaw and its boilers were built specifically to burn this type of coal, making it almost unique in Europe.

Steffan Messenger reports

But a tightening of environmental regulations on toxic nitrogen oxide emissions and the decision to make the station generate only at peak times mean only very tiny amounts of Welsh coal will be used in future.

Instead, coal from Russia and Australia - easier to burn and with fewer emissions - is being imported; although still in relatively small amounts.

Richard Little, station manager, has contracts until 2021 and still believes the plant has a role, until the next generation of energy suppliers can step up.

"Aberthaw will support the transition from a very coal-dominated UK generation system to a more gas and renewable future - we see ourselves as a bridge between those two things," he said.

"Although there have been periods over the summer when coal generation has fallen to zero, when margins are tight, the UK very much needs the capability of the remaining coal plants."

It has inevitably meant a scaling back and the station is undergoing its second round of redundancies in three years.

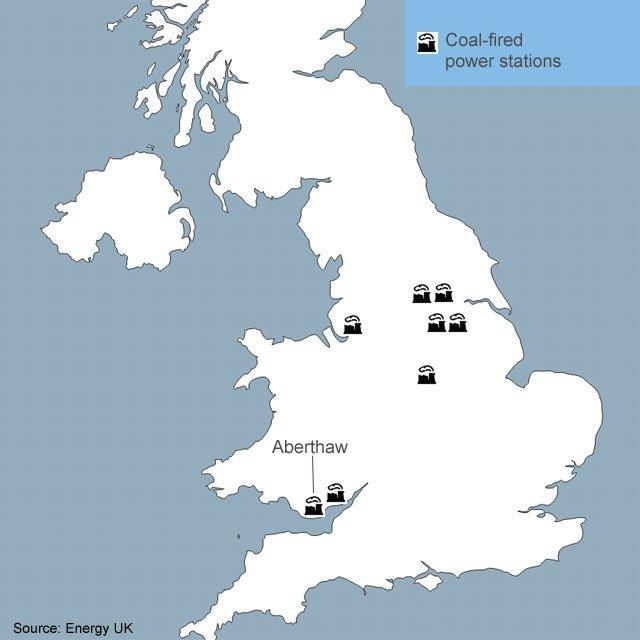

There are eight remaining coal-fired power stations in the UK

ABERTHAW: FACTFILE

Aberthaw 'B' opened in 1971 at a cost of more than £50m, alongside the older, smaller Aberthaw A power station

It employs a core of about 235 people but with contractors that number can more than double

It has a 1,500MW capacity, with the plant running 24 hours a day and workers covering four shifts.

It used 3.5m tonnes of coal in 2013 but that amount has reduced by 80%

Its coal has been brought by rail, mostly from opencast mines in south and west Wales. But this has changed with the need for new technology and sources with fewer emissions. It is now importing high volatile coal from Russia and Australia, which comes in through Cardiff and Avonmouth docks

The company said last year it would abandon its current production model to focus on generating electricity at the plant only when needed from 2017. The scale-back includes a current round of 35 voluntary redundancies

It is one of eight remaining coal-fired power stations in the UK, owned by six different companies

Geoff Jenkins hopes the plant can adapt further to survive

Geoff Jenkins, 60, agreed his voluntary redundancy on Wednesday and will be leaving in a few months after 37 years.

The operations supervisor has seen four different owners and what seems constant change, driven by economic and environmental factors.

"A lot of investment has been put in the plant to deal with emissions and to keep us on top and it has been continual since the early 1990s," he said.

"It has been a very exciting and good place to work but it's a battle because we know we're a coal station."

But he is hopeful there is a future, with two sons also at the plant.

"I've told them stay here as long as possible," he said. "The management are looking ahead at which ways we can survive, running differently - winter only and not summer. It could give us a chance to run maybe another 10 years.

"In that time, with the electricity market changing, the chances are we could end up as a combined cycle gas turbine site like Pembroke or Staythorpe [Nottinghamshire].

"As the workforce comes down, hopefully they can transfer. These lads have had to change and learn all new operating procedures - they've adapted to everything thrown at them."

Mr Jenkins added: "We'll be here from when there is shortage of supply in the winter, and be here when solar and wind power isn't available until nuclear and new gas comes on line, so we're topping it up and then they'll quietly close us down."

A "thank you" note from Tower was attached to the front of the coal train, as it arrived to unburden its wagons.

Mr Little said the end of a long history with the Hirwaun colliery had come a couple of years earlier than envisaged, with decisions taken over emission levels, but he fully understood the impact on both miners and power station workers.

"We've been working closely with them for a long time so they understand what's coming, and we were inevitably moving to a position where our consumption of Welsh coal was going to reduce," he said.

Environmental monitoring as part of the control room at Aberthaw

The European Commission took the UK Government to court last year, claiming it had been pumping out more than double the legal amount of nitrogen oxides for seven years.

Greenpeace claims shutting Aberthaw now on its existing emissions would save lives spread across Wales and England.

The environmental group's chief scientist Dr Doug Parr said it was time to think about the workforce rather than "eking out a little more profit" at an ageing station which was inevitably going to close.

RWE Generation defends its record and said local air quality standards had been within European and UK limits for the last 15 years.

Inside Aberthaw's control room, you can watch the furnaces burn on one screen, while monitoring emission levels for "SOX and NOX" - sulphur and nitrogen - air and water quality and noise. If any of the on-screen displays turn from green to yellow, this will be recorded.

Those in charge have not given up on Aberthaw having a future in some form.

"People are anxious to know what exists beyond this power station - and there is a possibility of future generation on this site," Mr Little said.

"But even if this doesn't happen, we're looking at options to move people to Pembroke where we have a big gas station and to re-skill people in readiness for that transition which will inevitably come for everyone."

The train from Tower carried 1,450 tonnes of coal - but this low volatile type of coal is being phased out

Coal is emptied from the bottom of the rail wagons onto a conveyor below

The coal is taken on huge conveyors into the power plant

Inside the turbine hall

Inside the control room, everything happening across the plant is monitored - from water, noise, emissions - but also current electricity demand in the UK

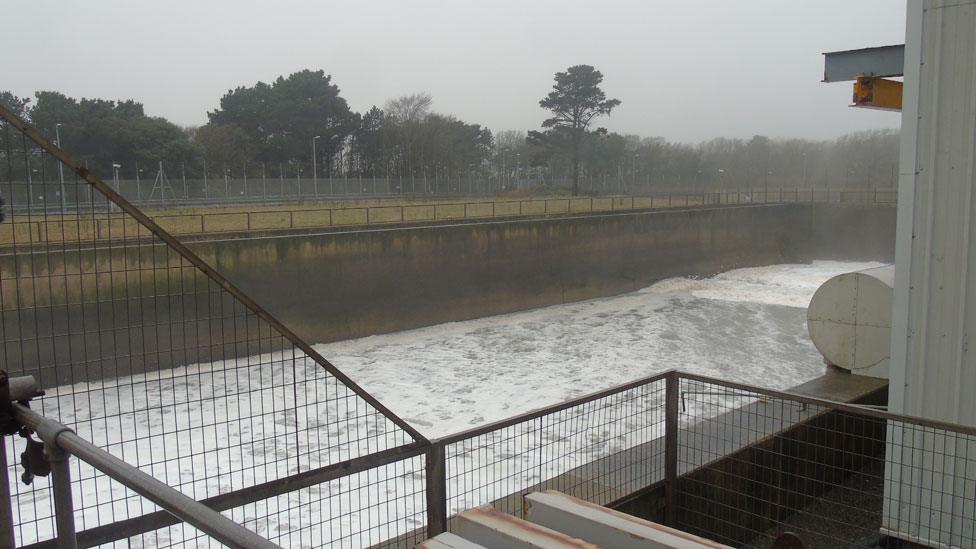

Nicknamed the "jacuzzi", sea water used in the process is cleaned of all its acidic properties before being returned to the sea

Coal stocks at Aberthaw are now lowest since the miners' strike - with half a million tonnes currently, although it can be as high as 1.5 to 2m

Biomass - including unusable wood - has also been used in the fuel process with coal but that will stop in October

The penultimate train from Tower Colliery carried a thank you message

- Published25 April 2016

- Published21 September 2016

- Published14 December 2016

- Published26 March 2015