Bridgend's Nodor: What goes into making a perfect dart?

- Published

Nodor will supply the boards at the BDO World Darts Championship

The second of darts' world championships steps up to the oche on Saturday, with the BDO World Championship coming five days after that of its rival, the PDC.

And while the players have been relentlessly sharpening their skills, Bridgend's Nodor International has been toiling to ensure their "arrows" hit the mark. But what goes into perfecting a top-class dart?

With its three brands, Winmau, Nodor and Red Dragon Darts, the firm is one of the world's biggest darts equipment manufacturers.

It has sold almost 40 million dartboards to more than 60 countries worldwide and 15 years ago it revolutionised the darts world by introducing the first mass-produced tungsten dart.

It was much smaller and lighter than the more traditional brass darts, according to Simon Hall, head of marketing.

"The weight loss gave player's greater accuracy and ability to group the darts in play," he said.

Simon Hall, of Nodor, explains the elements which make the perfect dart

"Each and every dart is checked and weighed by hand and we guarantee that all three darts in a set weigh the same, within 0.01 grams."

Today, many of the world's top professional players use the firm's tungsten darts, including Peter Wright, Gezzy Price, Jamie Lewis, Andy Fordham and Mervyn King.

But the work does not end when they leave the factory floor.

Many of the players want them specially customised to their throw; Wright, Lewis and Ted Hankey can often be found fine-tuning their darts on the production floor in Bridgend.

Darts player Peter Wright is known for his colourful hairstyles and clothes

Lee Huxtable, development engineer, said: "I'd have to say the fussiest player would have to be Mervyn King.

"He's prepared to travel from the far side of the country to come to the production floor in Bridgend just to show how he wants an adjustment on his dart.

"He could be here for 12 hours throwing and perfecting the dart. That change could be something as small as a hundredth of a milometer."

But Mr Huxtable said the player who keeps them the busiest is flamboyant PDC thrower, Peter Wright.

"He's well known in the industry for changing his darts as often as he changes his hair and his outfits, as he'll often make continuous little tweaks to the grip," he added.

"After the Grand Slam of darts, he sent me through a drawing of the changes he wanted made, so I've studied that drawing and transformed the sketch into these darts he wanted for the PDC World Championship."

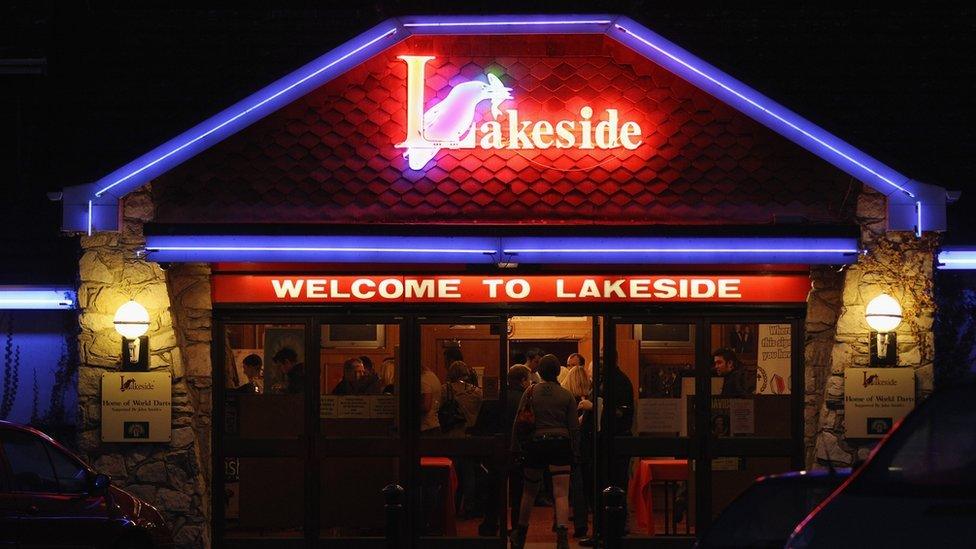

The BDO World Darts championship has been held at Lakeside Country Club since 1986

Lisa Ashton is the fourth seed at the 2018 BDO World Darts Championship

When it comes to the BDO World Championship 2018 at Lakeside in Surrey - often cited as the home of British darts - Nodor will supply the boards and many of the darts.

Jamie Hughes, the number three seed, is one of the players hoping Nodor's arrows will fire him to darts immortality, as well as the current women's champion, Lisa Ashton.

The company employs 500 people, between its Bridgend headquarters and its production plant in Kenya.

It says the best material for dartboard construction comes from the sisal plant, which grows naturally in Kenya.

The sisal plant is used to produce the Bridgend company's Winmau dartboards

A team from Wales is constantly on hand-managing operations there and the company harvests over 400 tonnes of sisal a day.

Explaining how the company has grown since the early days, Mr Hall said: "The Bridgend connection began when John Bluck, a former engineer at the Bridgend Ford plant, and father of current owner John, was invited to play a game of darts.

"He became fascinated with the equipment used and the challenge of improving darts equipment through innovative engineering."

Nodor bought Winmau in 2002, with the resulting combined firm going on to develop its "Blade" dartboard, which will feature at Lakeside, with a new board for each match.

- Attribution

- Published1 January 2018

- Attribution

- Published1 January 2018

- Attribution

- Published29 December 2017