Port Talbot Tata steelworks: What are the key issues?

- Published

A worker at blast furnace No 4 at Port Talbot

The town of Port Talbot has lived with uncertainty over its steelworks for years.

Although with only a fifth of the number working there than in its heyday, the plant still dominates the local skyline and remains one of Wales' biggest employers.

At the heart of Tata Steel's UK operations, there have been renewed fears that a decision is imminent on ending blast furnace operations at the works, which could hit thousands of jobs.

Here we look at some of the key issues:

Port Talbot in its heyday in the mid 1960s

Port Talbot: The headaches

It might be the car we drive, the washing machine in our kitchen, or parts of the house itself - the chances are we have a piece of Port Talbot steel close to hand.

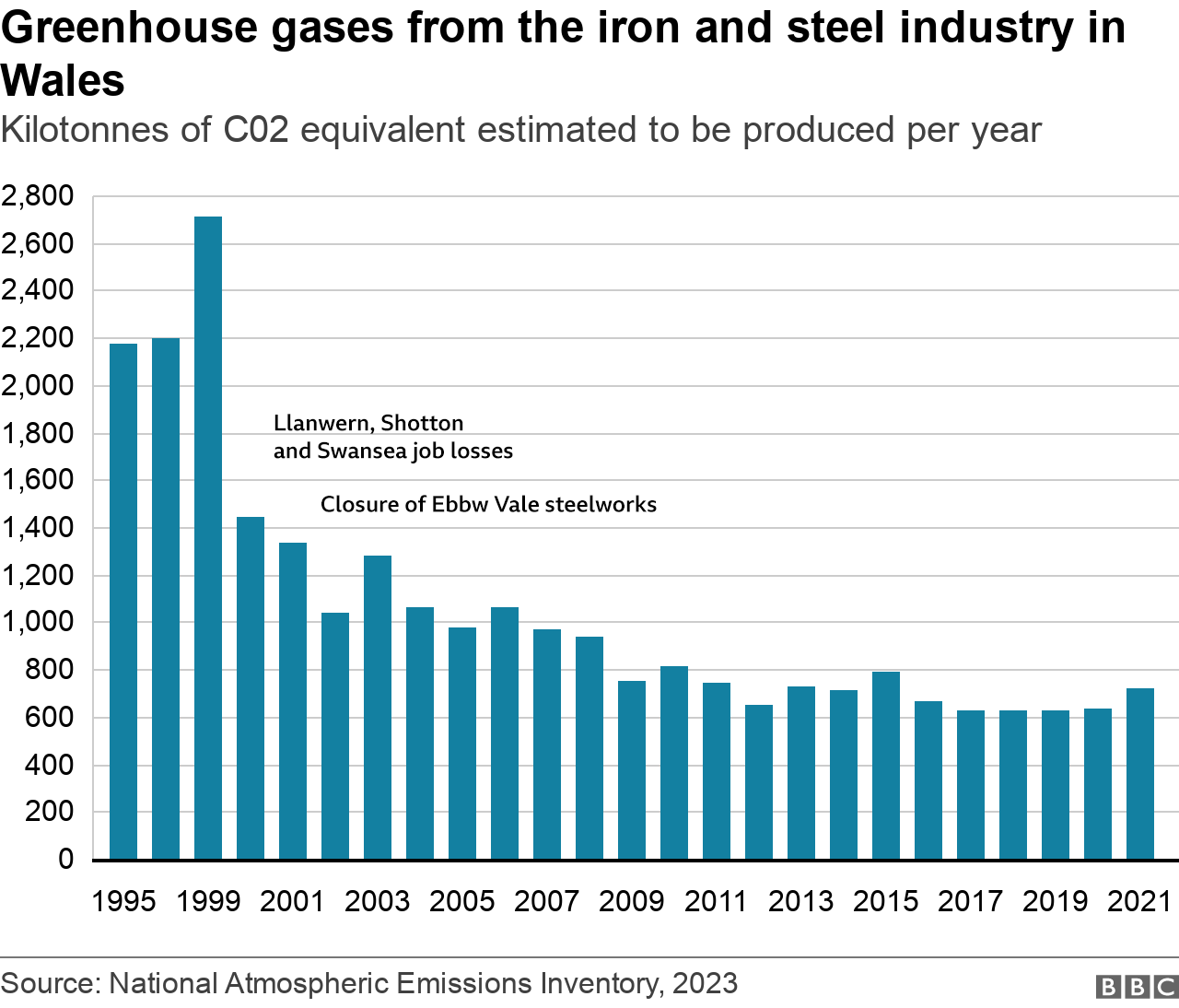

But steel production in Wales dropped to its lowest level in 20 years in 2022. There were 3.7 million tonnes of raw steel produced in Wales in 2022, according to the Iron and Steel Statistics Bureau. This is the lowest since 2002 and the closure of the Ebbw Vale steelworks.

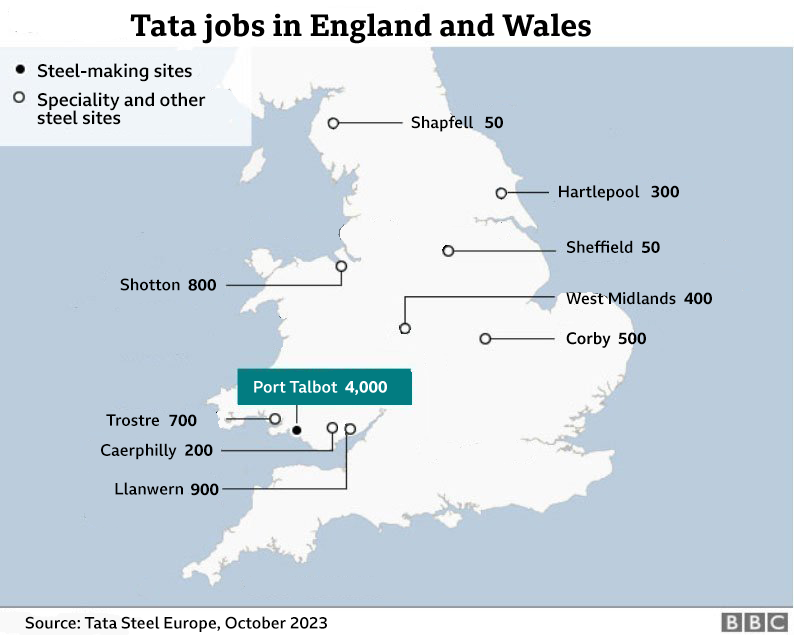

Tata employs around 8,000 workers in England and Wales, with half at Port Talbot

Provisional figures show UK production was at its lowest levels since the depression of the 1930s - with nearly two thirds of output from Wales.

Port Talbot itself produced around 2.8m tonnes in 2022, although that is expected to increase to closer to 3.2m tonnes this year.

There has been fierce international competition for years. In 2019, the UK produced seven million tonnes of steel, behind seven EU nations including Germany with 40 million tonnes. Meanwhile, China produced 996 million tonnes.

Steelworks also cost huge amounts to run because they use massive amounts of energy. The Port Talbot plant has by far the biggest bill and uses as much electricity, for example, as the whole of the city of Swansea a few miles along the motorway.

Because the UK steel plants are ageing, this can lead to unreliability and maintenance costs.

All this adds up and Tata's UK business has been said to be losing £1m a day.

But the biggest headache is the pressure to reduce carbon emissions.

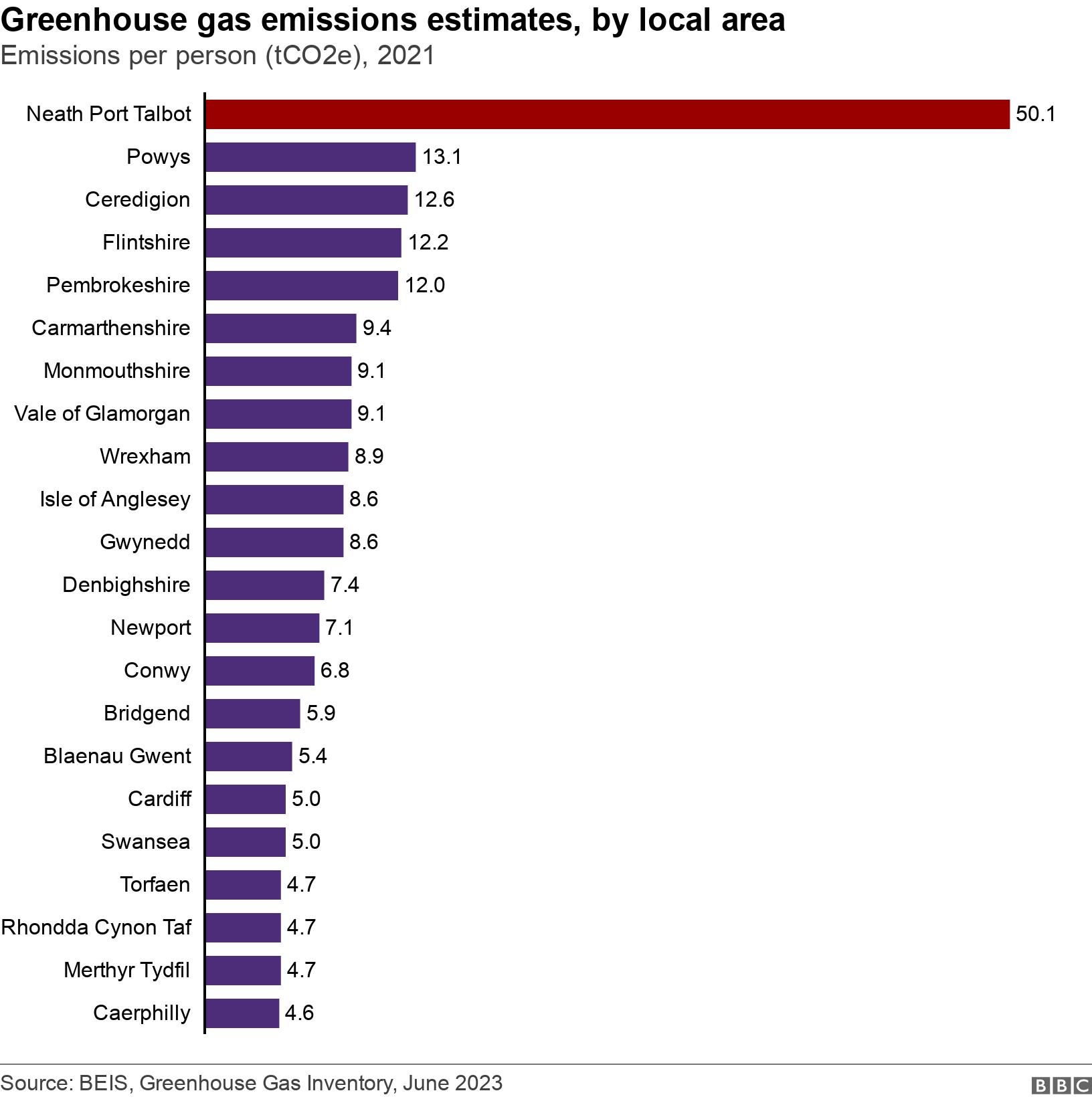

The steel industry in Port Talbot is the UK's biggest single carbon emitter and Neath Port Talbot has a share of getting on for a quarter of Wales' emissions., external

It's estimated that by moving away from the plant's existing coal-powered blast furnaces to a greener form of steel-making - using scrap metal as fuel - it could cut the UK's entire carbon emissions by around 1.5% at a stroke and Wales' greenhouse gas emissions by around 22%.

If we look at the scale of the issue another way. When the amount of greenhouse gases if it's broken down per person living in Neath Port Talbot, it's the highest in the UK outside London.

And it's way ahead of other parts of Wales - 10 times the amount produced in Cardiff or Swansea.

But unions and local politicians have called for a transition, to minimise the impact on jobs in the years it would take to get greener processes up and running.

Port Talbot: The importance

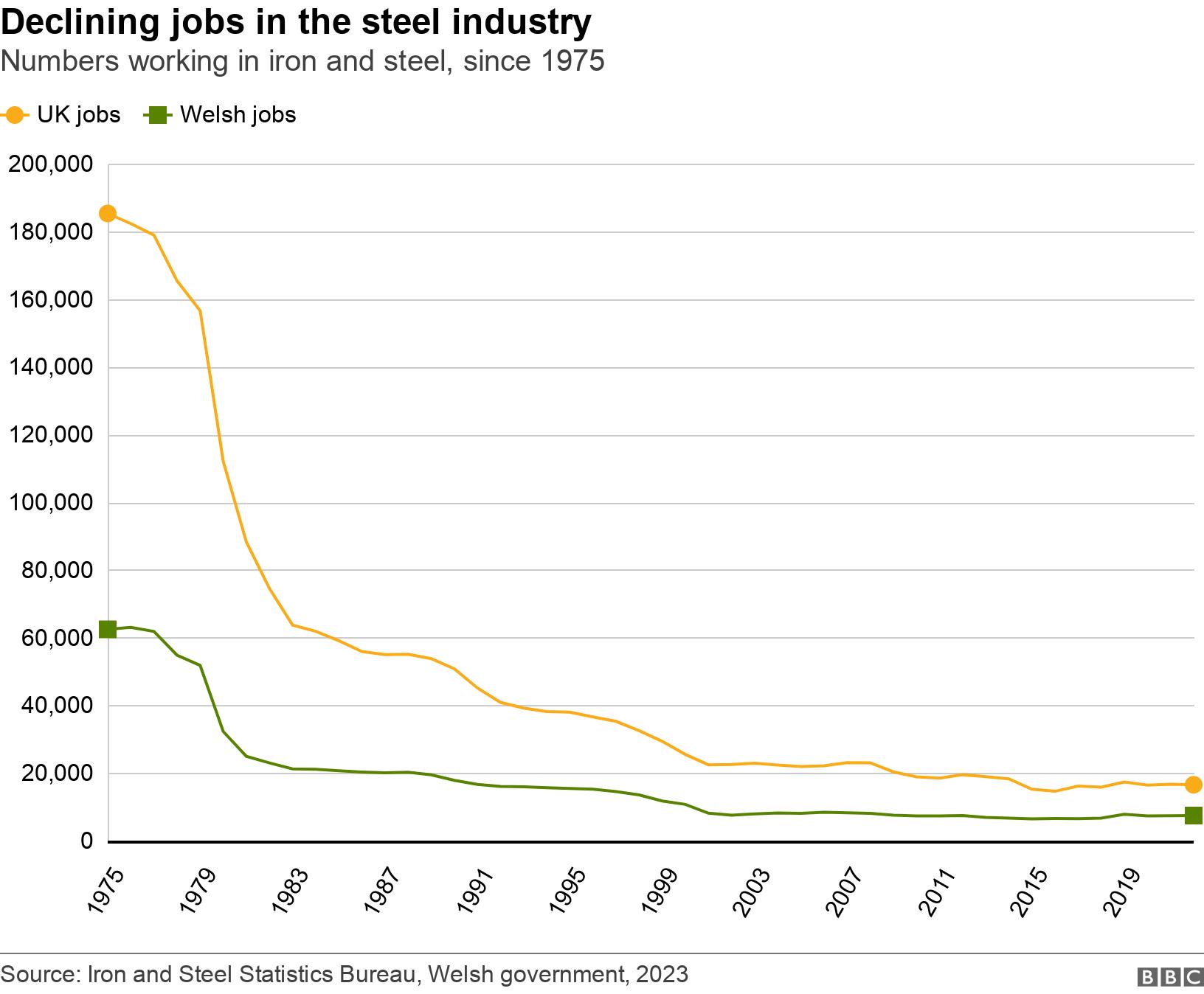

The heyday of the UK steel industry has gone - compared to the early 1970s when 320,000 worked in it, nearly 20,000 of them in Port Talbot.

Even in 1990, its importance to the whole economy saw steel worth 0.3% of total output. But by 2021 that was less than 0.1%.

But although there has been a decline, it is still important for local jobs. In Port Talbot the steelworks is synonymous with the community.

It dominates the skyline and Tata is still a big employer, paying more than double the minimum wage (more than a third higher than the average salary) and putting millions of pounds a year into the economy.

One economist who has studied the impact of Tata , externalhas called it "the most economically important private sector company in Wales".

Port Talbot in 1961

STEEL TIMELINE

1902: The first steelworks at Port Talbot is founded

1923: A second Margam works is finished

1947-1953: The third Port Talbot plant is built and becomes part of Steel Company of Wales. The works employ around 18,000 people. By this period, the rolling mill at Ebbw Vale has become the biggest of its kind in Europe.

Archive film of Port Talbot steelmaking in 1964

1962: The Queen opens the £150m Spencer works in Newport, later known as Llanwern.

1967: British Steel is formed from 14 different firms as the industry is nationalised

1980: British Steel announces 6,500 job losses with the closure of blast furnaces at Shotton after 78 years. More heavy job losses at Port Talbot and Llanwern.

1988: British Steel is privatised and becomes part of Dutch-owned Corus in 1999.

1990: More than 1,100 jobs are lost at Brymbo steelworks in Wrexham.

2001: Corus announces 6,000 UK job losses - a fifth of its workforce. They include 1,340 at Llanwern in Newport, and 90 at Bryngwyn , externalin Swansea. The Shotton cold strip mill closes, external with 400 redundancies.

2002: The Ebbw Vale steelworks shuts with 850 job losses, external, although 300 workers move to other plants.

2007: Corus bought by Tata Steel of India

2014: Tata blames high business rates and "uncompetitive" energy costs for 400 job losses at Port Talbot.

2015: Tata Steel reported a "turbulent year" due to Chinese exports and high energy costs but Port Talbot produced an all time record of 4.19m tonnes of hot metal while the hot strip mill hit speed-of-work records.

In August, it mothballs part of its Llanwern plant for the third time in six years, with 250 job losses.

2016: 750 job losses announced at Port Talbot and Tata explores the option of selling its UK business before announcing a five-year commitment to the two blast furnaces at the south Wales plant.

2019: £25m project to extend the life of Port Talbot blast furnaces completed.

2020: Tata's Orb plant in Newport closes after more than 120 years.

2022: Tata warns plants may close without subsidies for reducing carbon emissions. The Financial Conduct Authority (FCA) says British Steel pensioners could receive £71.2m in compensation if they were misled over poor advice when the scheme was restructured in 2017.

KEEPING THE FAITH: Can Wales stay at the top of their game?

KIRI'S TV FLASHBACK: Kiri Pritchard-McLean dives into the TV archives

- Published22 July 2022

- Published7 December 2016

- Published30 March 2016

- Published21 December 2015