Hiut Denim jeans worn by Meghan Markle shares secrets

- Published

The Duchess of Sussex - Meghan Markle as she then was - wore Hiut jeans on her visit to Cardiff in 2018

Their jeans hit the fashion pages in 2018 when Meghan Markle wore a pair to Cardiff Castle.

That was the Duchess of Sussex's first official royal visit to Wales.

Now the Welsh company Hiut Denim has opened its doors to TV cameras to reveal exactly what goes into making its version of the wardrobe staple.

The company, founded and run by husband and wife team David and Clare Hieatt in Cardigan, Ceredigion, has been making handmade jeans to order since 2012.

It employs 25 people and is currently producing about 10,000 pairs a year.

Clare said since the Meghan effect brought the small company 100 miles (160km) west of the Welsh capital to global attention its staff had become used to cameras.

Inside the Factory

Presenter Gregg Wallace was given access to the factory for an episode of BBC 2's Inside the Factory: Jeans.

Hiut has brought jeans production back to the mid Wales town of Cardigan

"When Meghan Markle wore our jeans we had the world's press on our doorstep, so our grand masters [workers], as we call them, have become used to being featured in things... it's good for business," added Clare.

Cardigan jeans

Cardigan has a long history of jeans making. For almost 40 years the town was home to a factory that made 35,000 pairs of jeans each week for giant UK retailer Marks & Spencer.

In 2002 that plant closed with the loss of 400 jobs when production was moved to Morocco to cut costs.

Then 10 years later, when the Hieatts were looking to open a factory to start making jeans, they chose Cardigan, employing machinists who had previously worked in the old factory.

Prince Harry and Meghan Markle were met with huge cheers at Cardiff Castle

The company name is a combination of the first two letters of their surname - Hieatt - and the word "utility".

The reference to its workers as "grand masters" acknowledges the fact that some of them have more than 40 years of jeans making experience. New joiners have to train for three years before they can start making jeans for customers.

Hiut jeans price

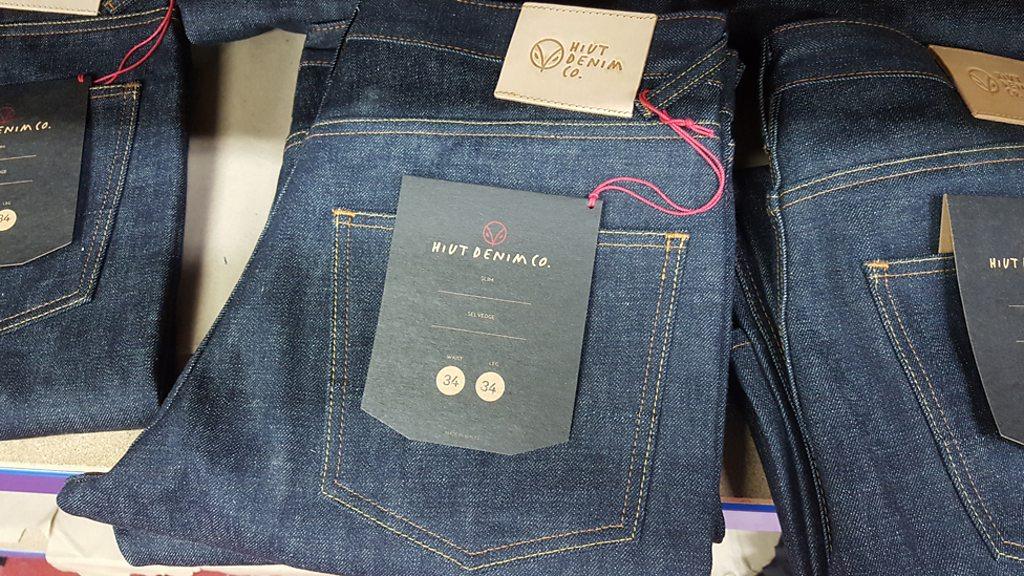

A single pair of jeans from the company can cost from £150 for their cheapest pair up to almost £300 for their most expensive pair.

In addition to visiting the Hiut factory, in his BBC2 documentary Gregg Wallace also visited one of Hiut's Italian denim suppliers, Candiani Denim on the outskirts of Milan.

There he saw the raw cotton being delivered, plucked, mixed, detangled, spun into yarn, dye and woven before the finished denim was dispatched to clients.

Back in the Cardigan factory, the cameras showed the company's pride in its role in returning jeans manufacturing to the area, with "our town is making jeans again" emblazoned on the wall.

Cardigan had a long history of jeans making before Hiut set up shop

Wallace also witnessed grand master cutter Claudio Belotti creating the 16 denim pieces that make up a pair of the company's jeans, before having a less successful go himself.

He then moved into the assembly area where grand master sewer Amanda Humphry began to sew the pieces together with different sewers working on each stage of the 27-stage process.

Copper buttons are added at one station, rivets at another, before the product is complete and ready to be sent out to the customer.

Was Clare nervous about revealing company secrets?

"No, we're very happy to share how our jeans are made," she said.

"The process of how are jeans are made is not unique, it's just the skills and craftsmanship of our team which is unique for us because they've got so much experience and the way that we do it."

Since the programme aired on Tuesday the company has been enjoying another moment in the spotlight, so much so it had to stop selling on their website.

Hiut staff make each pair of jeans by hand

"We've been getting lots of emails and we stayed late in the factory last night answering all the chatbot queries, loads and loads of queries in fact," said Clare.

"We've learned previously after the Meghan Markle exposure and we were inundated with orders and people were waiting three or four months for a pair of jeans," said Clare.

Instead they now release their slots for purchasing jeans in batches.

So what are the company's plans for the future?

With a more mature workforce, it wants to start a trainee jeans maker programme and is looking to take on two new recruits.

"Most of our makers are over 50 and we're very conscious we need new blood," said Clare.

"Hopefully they'll stay with us another 20 years."

Inside the Factory: Jeans is available on the BBC iPlayer

MEN UP: Five ordinary Welshmen embark on a surprising medical trial

UNMISSABLE DRAMA: When the Wolf is at the door, be very afraid

- Published13 December 2017

- Published13 December 2017

- Published18 March 2015