Royal Mint turning game consoles and TVs into gold

- Published

The Royal Mint - the UK's official maker of British coins - has unveiled a new factory where it plans to reclaim gold from electronic waste.

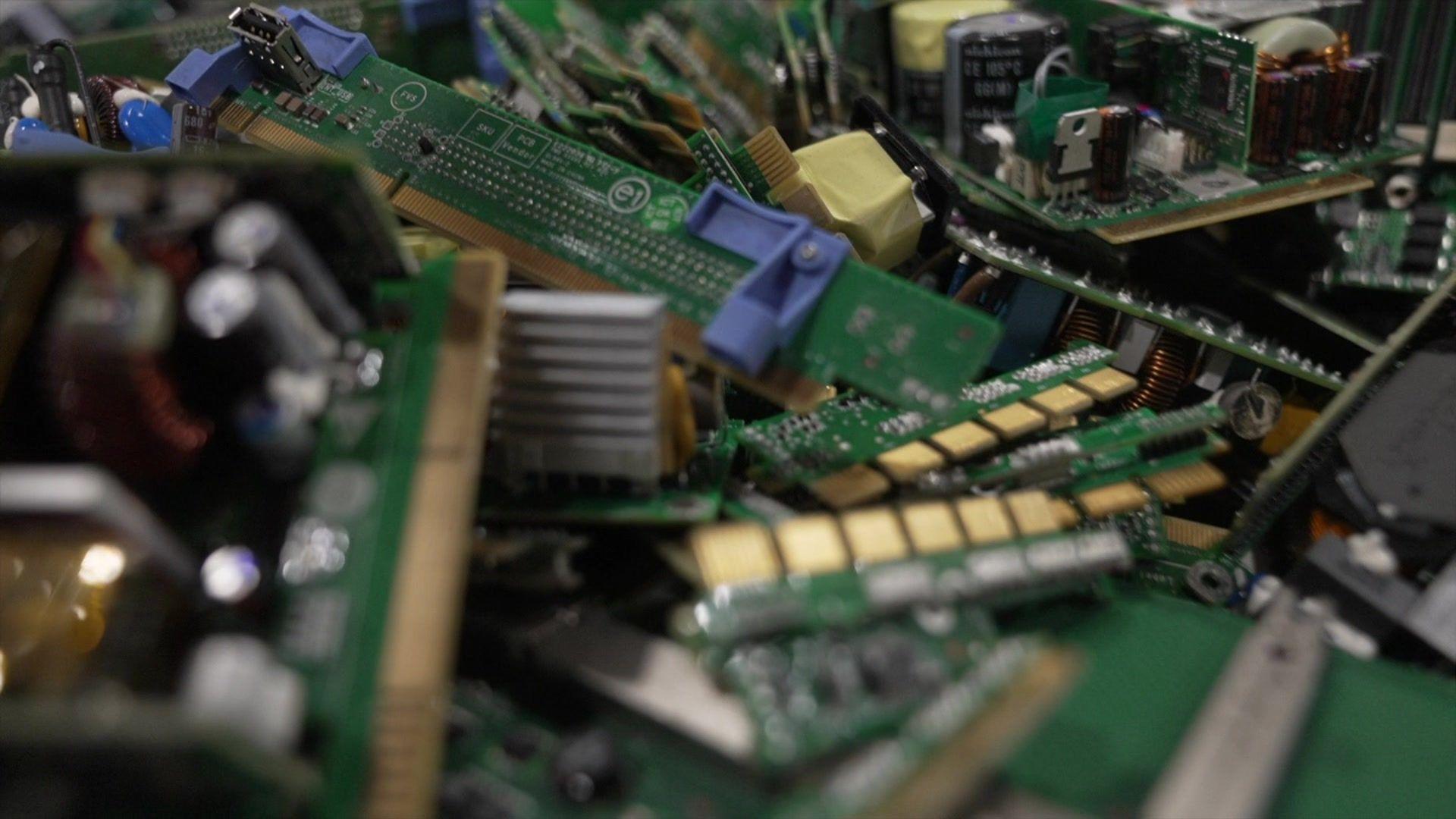

Every year, millions of tonnes of electronic waste like circuit boards from mobile phones, tablets and computers are thrown away.

But within those goods are some very valuable metals.

The Royal Mint has been using special technology to extract metals, including gold.

It plans to process up to 4,000 tonnes of printed circuit boards from e-waste a year in its Precious Metals Recovery factory.

It says the new factory provides a more sustainable source of gold and reduces reliance on mining.

It is also a new direction for the Royal Mint which is making fewer coins as people use cash less.

Report finds record levels of electronic waste around the world

- Published2 August 2024

What do you do with your old tech?

- Published3 April 2024

Scientists' salty plan to reclaim silver from solar panels

- Published15 September 2022

What is e-waste?

Circuit boards contain precious metals

E-waste is electronic waste, waste from electronic products.

A record 62 million tonnes of e-waste was produced in 2022, up 82% from 2010.

Less than a quarter was recycled that year and mountains of e-waste gets sent to landfill every year.

Mobile phone, computers and other electrical equipment contain circuit boards.

These boards use different metals, including small amounts of gold and copper to create electronic connections.

The global e-waste monitor estimated there was around £11 billion worth of gold in e-waste in 2022.

How do you extract gold from circuit boards?

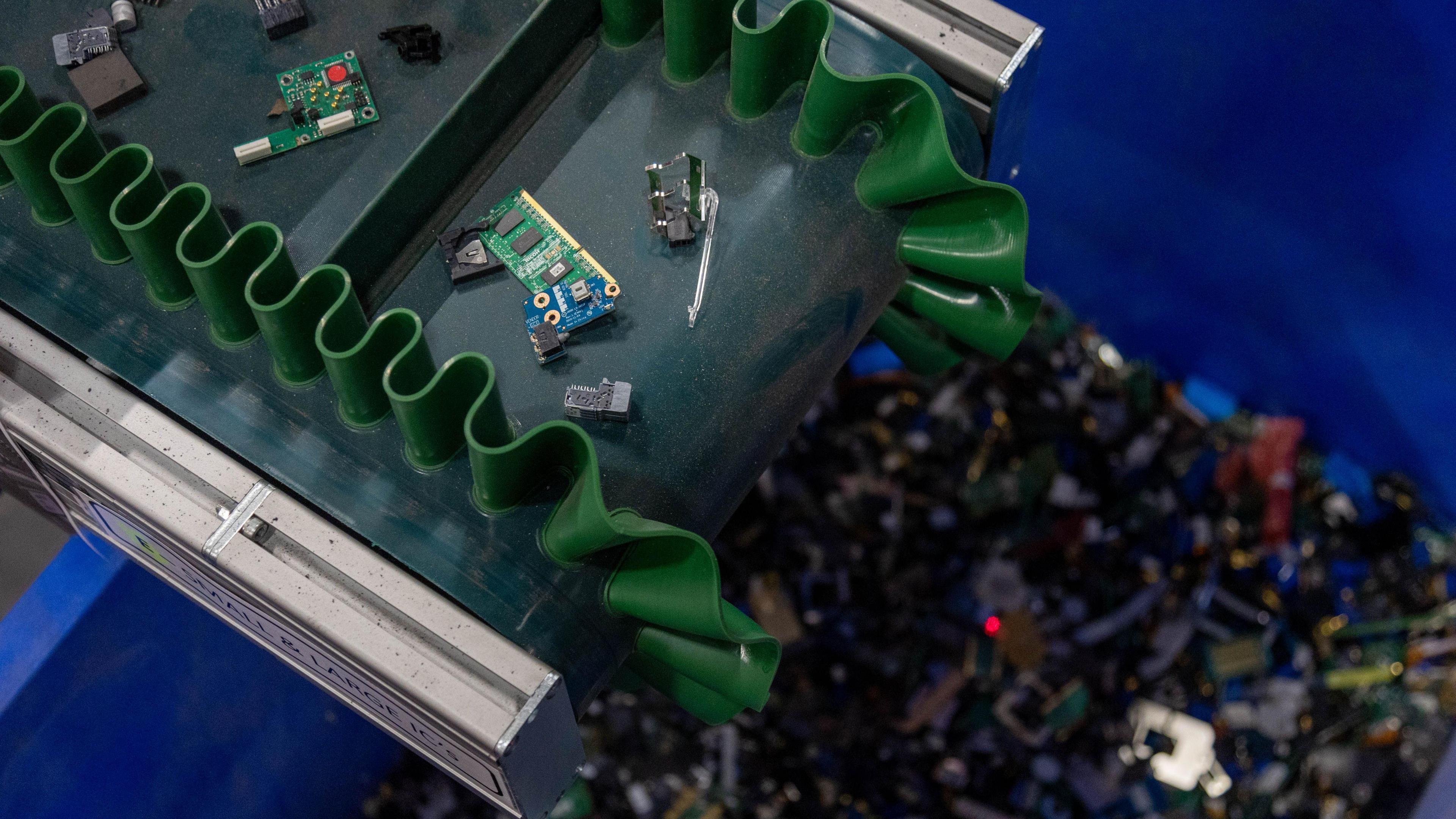

Circuit boards are pushed through a hot oven which heats them up so the components fall off.

The different components are then divided and anything with gold is set aside.

These pieces are then submerged into a chemical solution which extracts the gold turning it into a liquid which is then filtered.

The recovered gold is currently being used to make jewellery but will also be used to make commemorative coins in the future.

The new factory in south Wales will use this world-first patented chemistry to extract the gold.

The factory has the capacity to process up to 4,000 tonnes of PCBs from e-waste every year.

Sean Millard from the Royal Mint said: "The factory underpins our commitment to using sustainable precious metals and providing a new source of high quality, recovered gold.

"It allows us to reduce our reliance on mined materials and is another example of how we are working to decarbonise our operations."

- Published22 March 2022

- Published29 December 2023

- Published18 September 2019