Why was Glen Sannox so hard to build?

Watch: The Glen Sannox saga in two minutes

- Published

The ship at the centre of Scotland’s ferries saga has made its first scheduled voyage carrying passengers.

Glen Sannox is the second largest and the most complex vessel ever built for ferry operator Caledonian MacBrayne.

But the project has been hugely controversial, with the vessel finally being completed nearly seven years late and four times over budget.

So how did this story unfold and why was this ship so hard to build?

Challenging specification - or almost unbuildable ship?

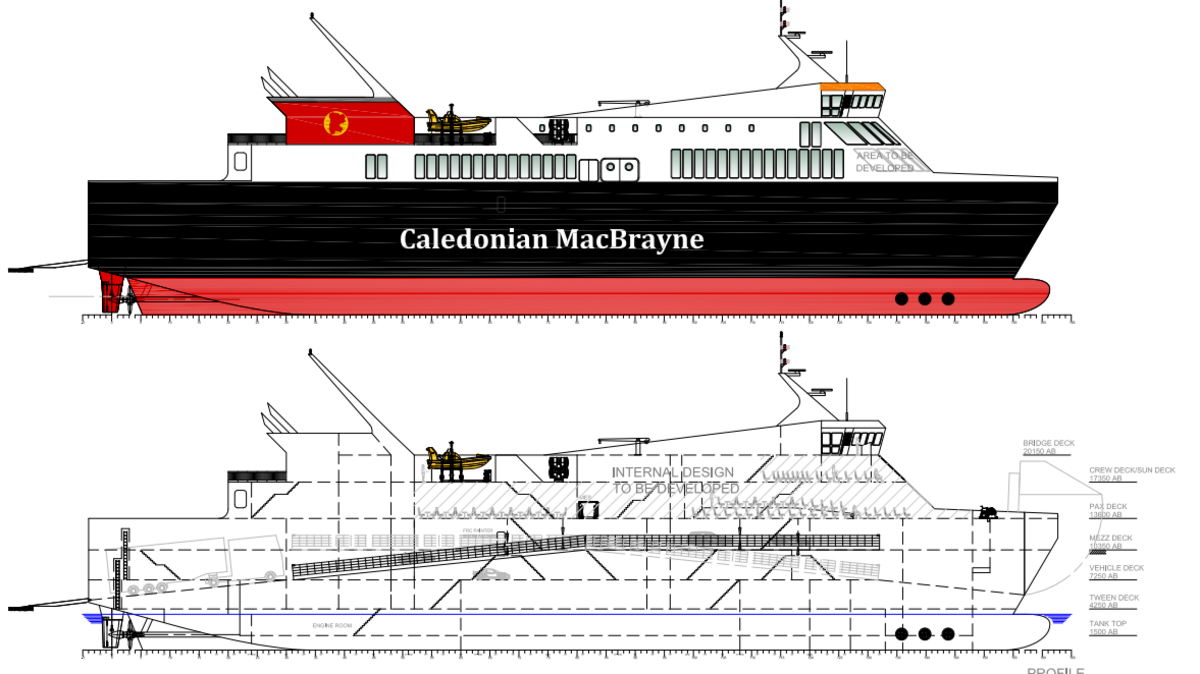

From the very outset Glen Sannox and its sister ship Glen Rosa were no ordinary CalMac ferries.

The specification, sent out to bidders in 2014, demanded a 25% increase in carrying capacity over existing vessels, but with little increase in dimensions.

They also had to be highly manoeuvrable and capable of navigating some of Scotland’s shallowest harbours.

The ships were to be identical yet capable of operating efficiently at two different service speeds. Fuel efficiency and reduced emissions were a "key requirement".

To achieve that, the ships were to be dual-fuel - able to run on both conventional marine gas oil and cleaner-burning liquefied natural gas (LNG).

The tender documents set out an exacting list of requirements for the new ships

Each of these requirements, taken on their own, were achievable - but together they posed a formidable design conundrum.

While LNG technology was well-established, especially on larger ships, only one bidder had experience of building them and it was new territory for UK regulators.

Documents leaked to the BBC two years ago revealed that ferry operator CalMac and CMAL - the government-owned company which owns and procures the ferry fleet - were frequently at loggerheads over the specifications.

Design consultants engaged by CMAL, whose role it was to check the ships were feasible, proposed relaxing some requirements but CMAL decided to stick more closely to CalMac's original requests.

Some critics claim this initial "concept design" stage was rushed and poorly-developed, specifying an almost unbuildable ship - and that this sowed the seeds for the problems that arose later.

CMAL denies this, pointing out that five of the six bidders (including Ferguson's) submitted designs which claimed to meet the key requirements.

But just weeks before CMAL chose a preferred bidder, CalMac's head of ship design issued a warning which in hindsight looks prophetic.

He said all of the bidders' technical documents were "under-developed" - and that "major issues" needed to be resolved before contract award "to avoid costly variations and delays during design and build of the new ships".

CMAL says the winning bid was "refined" and clarified before the contract was awarded.

A questionable procurement

When the challenging specification for the ferries was first drawn up it was almost certainly expected that a large overseas shipyard would build them - but things soon changed.

In August 2014, just weeks before the Scottish independence referendum, Ferguson Shipbuilders in Port Glasgow went into administration.

First Minister Alex Salmond took a personal interest in saving the last commercial shipyard on the River Clyde, brokering a deal for it to be taken over by an investment firm led by pro-independence businessman Jim McColl.

Alex Salmond played a key role in persuading Jim McColl to rescue Ferguson's

After a decade of decline, Ferguson's only employed 76 staff and was in desperate need of modernisation. When Salmond proposed getting the TV cameras in, one worker jokingly suggested the Antiques Roadshow.

But McColl, through his investment firm Clyde Blowers, was soon promising a multi-million pound redevelopment and a shipbuilding revival in one of Scotland's most deprived areas.

It was a vision many people were understandably keen to get behind.

A direct award for a small CalMac ferry quickly followed - but the new owners were also eyeing up the much larger ferries contract, about to go out to tender.

Some have since questioned whether these ambitious, complex ships were the right kind of project for the small shipyard to take on so early into its journey of recovery.

'Rigged' ferries deal probe finds no evidence of fraud

- Published18 October 2023

KC’s ferries report: What questions remain?

- Published3 November 2023

Even though Ferguson’s design proposal was by far the most expensive, two CMAL managers tasked with judging the bids declared it the best in terms of "quality".

They awarded it the highest scores in every category, outranking some of Europe's top shipyards - including a world leader in LNG ships.

CMAL has insisted the evaluation was conducted fairly, and the winning bid was judged solely on its merits.

But two years ago, a BBC Disclosure documentary - The Great Ferries Scandal - presented evidence the procurement may have been rigged.

Ferguson's highly-scored technical specification was almost identical to a document produced months earlier by ferry operator CalMac.

Ferguson's technical specification was found to be largely copied from a document produced months earlier by CalMac, which no other bidders had access to.

It was also revealed that the shipyard initially proposed a heavier ship - but CMAL's evaluators prompted the yard to switch to an earlier, lighter variant even though Ferguson's designers had doubts about whether it could meet the specification.

It was then scored on this alternative design.

CMAL rejected the documentary's claims and commissioned a KC-led review which found no evidence of "criminal corruption".

The KC's remit did not extend to examining whether procurement rules were broken, and the BBC stands by its journalism.

Design struggles and building 'at risk'

Construction of the two ships got under way in 2016 but in difficult circumstances.

Modernisation work was still ongoing at the shipyard. Old buildings were being ripped down and a huge new module hall was under construction.

In its original bid for the contract, Ferguson's had proposed building the two ships one after the other, delivering them nine months apart.

But by now the new managers had decided to build them simultaneously, side-by-side on the yard's narrow slipway. Some workers doubted whether that was feasible.

A bigger problem was that detailed design work for the ships was falling behind as the design team struggled to come up with a solution that ticked all the boxes and satisfied the customer, CMAL.

CMAL asked if the engines could be downsized - but the shipyard soon reported this was impossible unless other specifications were relaxed.

Weeks of design time were lost waiting for key decisions to be made.

The steelwork for Glen Sannox was completed - but the design work and approvals by CMAL lagged behind

Meanwhile, the yard's new production manager, anxious about hitting fabrication milestones, instructed the workers to press ahead with the steelwork.

At first the yard focused on sections of the ship where they were confident the design would not change. That's not uncommon in commercial shipbuilding.

But as months slipped by with design challenges proving intractable and the relationship with CMAL breaking down, Glen Sannox was increasingly built "at risk" - without drawings that were approved by the customer or regulators.

One worker has described it as like trying to build an Airfix model but finding out the instructions were missing.

It was late February 2017 before even the final hull shape was finalised - by which time the steel fabrication on Glen Sannox was 60% complete.

Glen Sannox was launched in 2017, pictured left, but much work was still required before it was ready for delivery in 2024, pictured right.

Much attention has focused on the "painted-on windows" when the ship was launched by Nicola Sturgeon in November 2017 - but more significant were issues that could not be seen.

There was a huge amount of "fitting out" work still to do inside the ship - things like pipework and cabling.

It was work that could have been done far more efficiently in the sheds or while the ship was still on the slipway.

CMAL later claimed the ship was launched prematurely simply to trigger another milestone payment and ease the firm's cashflow problems.

Jim McColl denies that - he says the early launch was essential to clear space for Glen Rosa after CMAL interference messed up his firm's build strategy.

Gunfight at the OK Corral

The already fraught relationship between the shipyard's management and CMAL plummeted to a new low in July 2017 when the yard presented an itemised bill for an extra £17.5m in costs.

CMAL's chief executive Kevin Hobbs was raging. He insisted it was a fixed price contract - a claim denied by Jim McColl - and refused to pay any extra.

The two sides saw the dispute from completely different perspectives.

McColl argued that a flawed concept design, slow decision-making, repeated interference and change requests by CMAL were to blame for unforeseen delays and costs.

CMAL claimed the problems were purely down to bad decisions and planning by his managers - and a failure to grasp the complexity of the task they had taken on.

McColl wanted an independent technical review to settle the matter swiftly; CMAL saw it as a matter best decided in the courts and challenged him to sue.

The workers who saw Scotland's ferries saga unfold

- Published27 September 2022

Ten things we learned about Scotland's ferry fiasco

- Published27 September 2022

Trade union representatives described the standoff as like the "Gunfight at the OK Corral" - the famous showdown involving Wild West lawman Wyatt Earp.

"They had come to loggerheads and could not agree on the design," GMB convener Alex Logan told a parliamentary inquiry., external

"We could not move forward so things just came to standstill."

With the shipyard running out of money, ministers controversially sidestepped CMAL by giving the yard two loans totalling £45m, little of which was recovered.

By 2019 - with the ships by now a year late - the build was in crisis and CMAL was ready to cancel the contract for Glen Sannox.

A last-ditch offer from McColl to split the cost of finishing the two ships - now estimated at £100m - was rejected by ministers on grounds it would break state aid rules.

In August – five years after Jim McColl rescued Ferguson's - the administrators were called back in again.

Nationalisation, Covid and the £2m 'turnaround director'

The government nationalised Ferguson's - which avoided redundancies - but any hopes of an end to the troubles quickly faded.

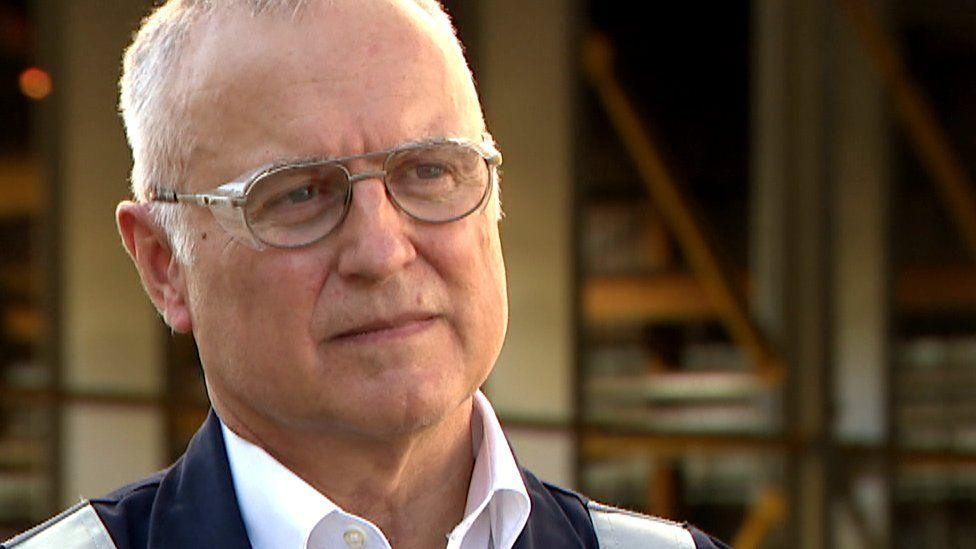

After a telephone interview, the government appointed Tim Hair as "turnaround director", paying him £2,850 a day plus expenses.

Five months into the job, he delivered a report, external which heaped blame on the previous management and asked for an extra £110m to finish the two ships.

“Remedial work” included scrapping hundreds of already-installed pipes because the yard had used a type of joint that wasn't authorised by CMAL.

Tim Hair was paid nearly £2m during his term as "turnaround director"

The Covid pandemic forced a temporary halt to production in 2020 - but that wasn't the only problem.

During lockdown newly-appointed design partners based in Romania sent nearly 20,000 drawings to the shipyard at a time when there were barely enough staff on site to catalogue them, let alone approve them, MSPs have been told., external

One of the reasons the old Ferguson Shipbuilders had outlasted other Clyde yards was that it had a lean management structure and was always counting the pennies.

The workers were by now becoming increasingly worried, not just about mistakes - but also the burgeoning numbers of managers and consultants being brought in.

In late 2021 they threatened a no-confidence vote in the management team. A short time later ministers announced Tim Hair was moving on.

In one of his last updates, he revealed that 1,400 cables installed prior to nationalisation were too short to reach equipment. It later emerged that part of the problem was that control panels were moved during redesign work.

Tim Hair left at the end of January 2022 having been paid nearly £2m for 595 days’ work.

David Tydeman tried to repair the broken relationship with CMAL

When new boss David Tydeman took the helm, he found the design of the ships was still far from nailed down, more than six years after the contract was signed.

His approach was to try to heal the long-broken relationship with CMAL, seconding one of their senior staff as project manager.

With so much redesign work and the ship having been in the water for years, it was no longer just a newbuild but was also a repair and retrofit project.

Rusty prop shafts had to be renewed - and fitting all the LNG equipment into the ship's small machinery spaces proved difficult.

Tydeman described the engineering challenges as more complex than the Royal Navy's new frigates being built upriver in Glasgow.

Gradually the ships made progress - but at huge cost. As new problems were uncovered, the bill to complete them soared to about £300m.

When you add in the £83m paid out prior to nationalisation and the £45m of loans, the ships were now costing more than four times the £97m contract price.

Glen Rosa was launched 1,000 tonnes heavier than its sister ship Glen Sannox was at its launch five years earlier

There was a rare moment of celebration in April last year with the launch of Glen Rosa, far more complete than its sister ship when it entered the Clyde five years earlier.

But David Tydeman wasn't there to see it - the Ferguson Marine board sacked him weeks earlier after another deadline for the delivery of Glen Sannox was missed.

His successor had the misfortune of having to announce a further four short delays before the ship was finally handed over to CMAL and CalMac.

The final chapter

With Glen Sannox now entering service, it looks like Scotland's ferries saga could finally be drawing to a close.

An irony of the story is that a contract once seen as a lifeline for the shipyard has left its future far more fragile than before.

Ferguson's has built more than 360 vessels in its proud 121-year history - including many stalwarts of the CalMac fleet - but is currently best known for just two.

Will the shipyard secure new orders and demonstrate that the difficulties with these two ferries were an aberration born out of a unique combination of circumstances?

That's a chapter yet to be written.

Related topics

- Published20 April 2024

- Published26 November 2023