Bright light of hope in electric arc furnaces

The old steelworks structures have been demolished

- Published

First, there is employment.

It's no surprise that this is at the forefront of people’s minds when asked about the prospect of steel-making returning to Teesside.

"I think it would be a really good thing - there were a lot of jobs lost when it went," says the first person I ask about it on Eston High Street.

"More jobs, definitely more jobs," says another. "The next generation needs jobs," says the next.

"There’s so many men in Grangetown, Eston and South Bank that are out of work," says another still. "I think it would be great."

Then there is emotion.

Middlesbrough and its surrounding area was built on the steel forged along the banks of the Tees. This is found in iconic structures all over the world, from Sydney Harbour to Bangkok and Zimbabwe.

"Bringing steel-making back to Teesside is a hugely significant moment in our particular story of regeneration and renewal," says local Conservative MP Sir Simon Clarke.

Conservative MP Sir Simon Clarke said bringing back steel was "hugely significant"

But, if British Steel does go ahead with its plan to build an electric arc furnace on Teesside, there will be another impact to consider: the environment.

Traditional steel-making relies on huge amounts of fossil fuel to power the blast furnaces that turn iron ore into molten iron.

An electric arc furnace uses electrolysis to melt scrap metal. So, if that electricity can be produced using a renewable source like wind or solar power, it can provide a sustainable way of making steel.

"It is quite spectacular," says steel expert Jon Bolton. "Because essentially you are putting electrodes into scrap and melting at high temperature.

"But it is a simple process and a proven process.

"Moving from blast furnace technology to electric arc technology is an important step, both to decarbonise the industry but also to make it more competitive."

Recycling scrap metal with an electric arc furnace is "simple", experts say

Few people are better placed to assess the impact the potential new furnace could have on Teesside.

Mr Bolton started working in the industry in the 1980s and was a key figure when the Redcar blast furnace was mothballed in 2009.

He is now the executive chairman of the Materials Processing Institute, which has a working electric arc furnace in its South Bank research centre.

He says having one at British Steel would be a very positive first step, but it would have to be followed by a lot of investment in other technologies to make it transformational for the region’s industry.

Jon Bolton started working in the industry in the 1980s

"There is a finite amount of scrap around. There probably isn’t enough to support all the electric arc ambitions in Europe," Mr Bolton says.

"So you need to find a way to manufacture and generate iron units.

"Can it expand? Yes it can, but it depends on what else is put in place and whether more iron and steel making capability can be added to what is already being proposed."

The British Steel Electric Furnace would be built at Lackenby and would supply metal both to the beam mill there and to the special products plant in Skinningrove.

It’s estimated it will create 250 direct jobs but local people hope it will be the start of something bigger.

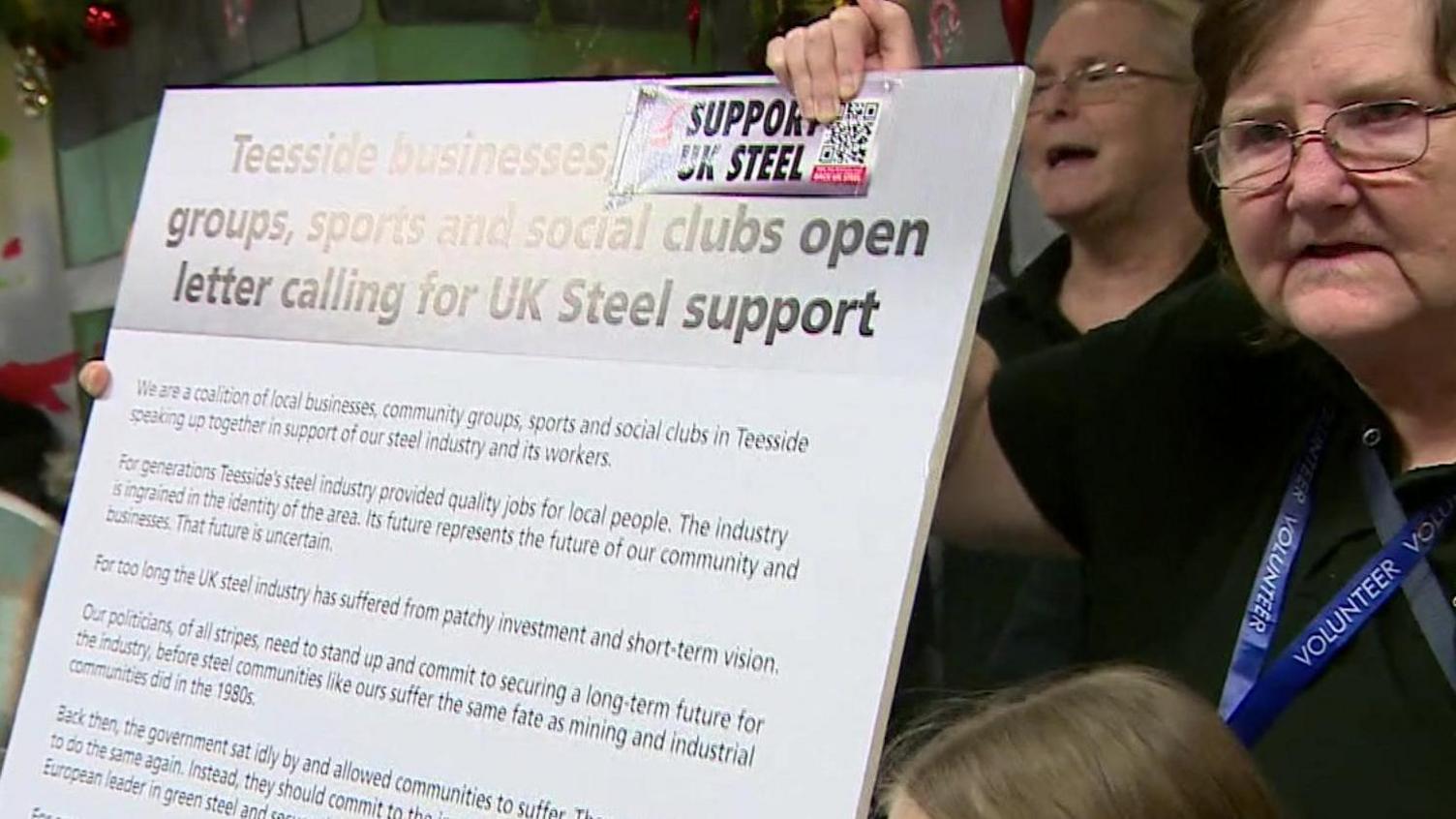

More than 130 business and community leaders on Teesside joined the Unite union to sign an open letter to politicians, demanding more investment in green steel production and greater use of British-made steel in public buildings.

An open letter to politicians is demanding investment in green steel production

"What we need to see is a transition from carbon-producing, intensive steel making to utilising green energy to produce green steel," says Unite’s Pat McCourt.

"We believe, from our research, that this country could create 8,000 jobs if the government takes a proactive approach and invests."

But how much can local politicians do to make those things happen?

Conservative Tees Valley Mayor Ben Houchen pledged to bring steel making back to Teesside when he campaigned for re-election in 2021.

His party colleague Sir Simon says the proposed arc furnace and the use of British steel in big building projects locally proves they have fulfilled that promise.

"I think it’s overwhelmingly likely that this will go ahead," he says.

"The new SeAH offshore wind turbine factory that is currently going up at Teesworks is being built of British steel and that is a really good example of us practising what we preach."

The Redcar blast furnace was the last of about 100 that used to line the River Tees

Labour’s Tees Valley mayoral candidate, Chris McEwan, says he would lobby government for money to bring traditional steel-making back to Teesside, using sustainable green hydrogen in place of carbon-heavy fossil fuels.

"Labour’s got a commitment to invest up to £2bn into green steel," he says.

"So an electric arc furnace will give us one element of the jigsaw but the other element is to get primary steel making back, which I think is very important from a strategic perspective for the Tees Valley and also nationally."

If British Steel’s plan to build the furnace on Teesside goes ahead, it won’t replace what was lost when the Redcar steelwork closed down.

But many hope it could be the spark of something new.

Follow BBC Tees on X (formerly Twitter), external, Facebook, external and Instagram, external. Send your story ideas to northeastandcumbria@bbc.co.uk.

Related topics

- Published29 June 2023

- Published27 November 2023

- Published6 November 2023

- Published1 October 2022