Fruit-picking robots help to tackle labour crisis

Dr Vishwanathan Mohan helped to design the prototype at the University of Essex

- Published

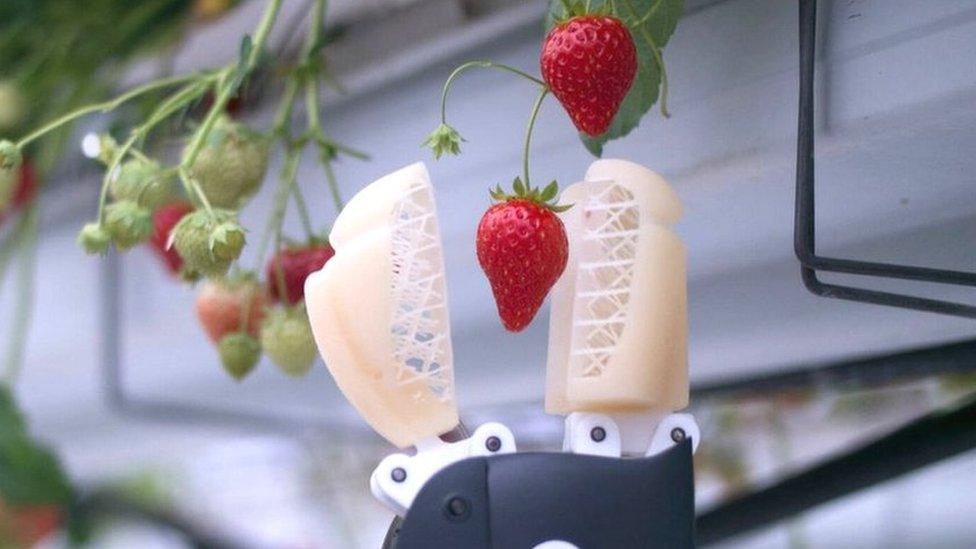

Strawberry-picking robots have been called upon to tackle a labour crisis in the industry.

The artificial allies could harvest and package the fruits "in a matter of seconds", according to the University of Essex.

Prototypes being tested by researchers at Tiptree-based jam makers Wilkin & Sons cost £10,000 - a fraction of the existing robots' £150,000 price tag.

"Robotics is a game changer to tackle some of the critical challenges facing us – food security, labour security, climate and energy," Dr Vishwanathan Mohan said.

Using a robotic arm, the machine can pick a strawberry in 2.5 seconds before weighing it and placing it in packaging.

The university said it could be easily adapted to other crops, with harvesting trials also planned for onions, tomatoes and lettuce.

The project is being funded by a £1.02m grant from the Department for Environment, Food and Rural Affairs

Dr Mohan, from Essex's school of computer science and electronic engineering, external, designed and built the robot with Prof Klaus McDonald-Maier.

"Through this project we want to transform how food is grown efficiently using robotics and AI, and make state-of-the-art agri-robotics technologies accessible to everyone," said Dr Mohan.

"Even if smaller farms and businesses can afford a robot, you need a whole fleet of them to make a difference, so it is vital we find cost-effective alternatives to help the agricultural industry with labour shortages."

'Inordinately complex'

The project was funded by a £1.02m grant from the Department for Environment, Food and Rural Affairs.

It was hoped the scheme would reduce the repetitive, labour-intensive process of crop-picking while extending the products' shelf life.

Chris Newenham, a director at Wilkin & Sons, said it was helping to tackle "the most significant challenge" for the industry.

"These challenges are inordinately complex and take time, it is work which is definitely not for the faint-hearted," he added.

"But we are confident that we are working with the very best partners and very much looking forward to seeing the fruits of our collective labours over the coming years."

Get in touch

Do you have a story suggestion for Essex?

Follow Essex news on BBC Sounds, Facebook, external, Instagram, external and X, external.

Related topics

- Published8 May 2024

- Published25 May 2018