How Sicilian oranges are being made into clothes

- Published

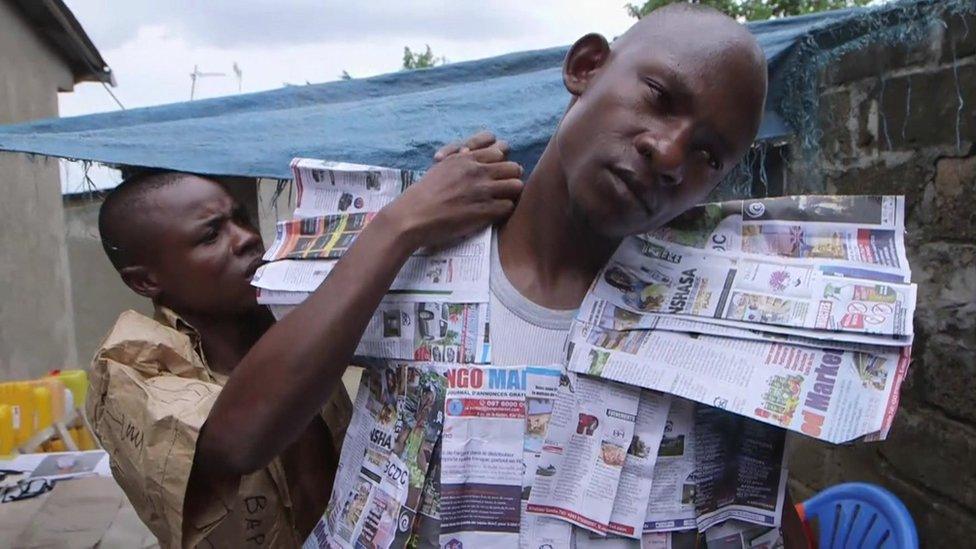

The fibre made from the oranges can be blended with other yarns to make clothing

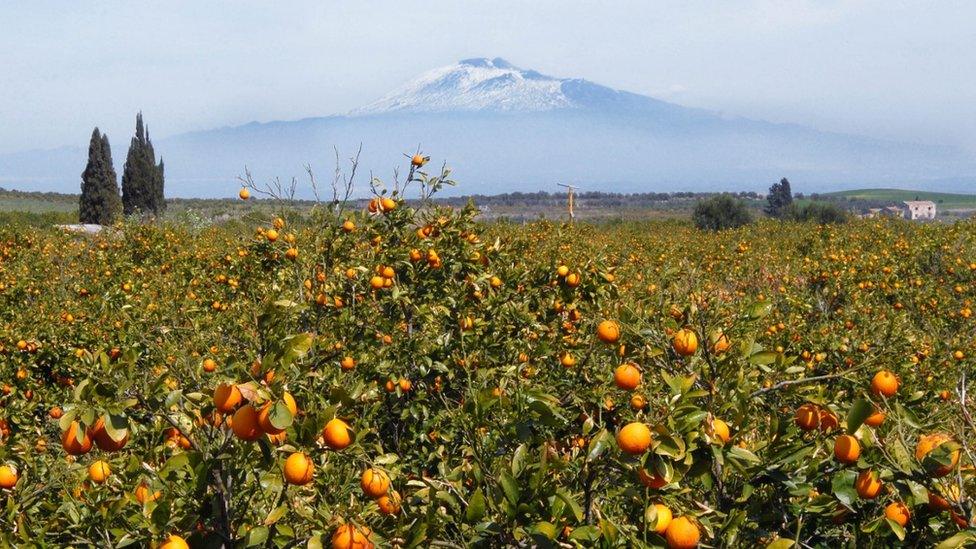

From fashion to energy - the rind and seeds of Sicily's most famous citrus fruit, the humble orange, are being used in a range of greener, healthier business initiatives.

In 2011, Adriana Santonocito was a design student in Milan when she first had the idea of making sustainable textiles from what was naturally abundant, and widely wasted, in her native Sicilian city of Catania.

Her challenge was to find a way for the rinds of hundreds of thousands of tonnes of oranges to be put to good use.

Now, thanks to her creative thinking, it is possible to make whole items of clothing using fibre that originated from the fruit.

Chemical process

Ms Santonocito's concept was inspired by a question posed in her university dissertation. Could a luxurious silk foulard be made from citrus by-products, that would otherwise be thrown away or fed to cattle?

Orange Fiber uses chemical reagents to separate the cellulose from the orange remains

The question was particularly relevant in Sicily, where many thousands of tonnes of citrus fruit are juiced every year, leaving massive amounts of waste.

The 39-year-old found her answer in the university's labs, and it earned her a patent.

It was already known that cellulose could be extracted from orange rinds. But Ms Santonocito discovered that, using chemical reagents, it could then be turned into yarn, which could be dyed and blended with other textiles, such as cotton or polyester.

Together with her university colleague Enrica Arena, she founded Orange Fiber in 2014, and set about selling the silk-like material to clothes-makers.

Adriana and Enrica now head up a 12-strong team

This year, the famous Italian fashion label Salvatore Ferragamo used it in its spring-summer collection. The aim was to make its high-end shirts, dresses and foulards more sustainable.

Orange Fiber, which now has a team of 12 people, operates from a local juice-processing plant, where it gets its waste material for free.

The business is partially seasonal, operating during the months of the year when the juice-maker works. But once the orange rind has been transformed into cellulose, it can be put in storage for use later.

Antonio Perdichizzi, an early investor in Orange Fiber, says the firm stood out to him because, unlike most innovative start-ups in Italy, it isn't digital.

Orange Fiber uses the rinds of juiced oranges

"Italy doesn't invest much in innovation, but brilliant ideas and skills win despite a lack of resources," he adds.

Rosario Faraci, a professor of business, economics and management at the University of Catania, says the firm is an example of how "creativity and entrepreneurial spirit" is creating new jobs and businesses in the region.

Fibre - not fat

Oranges could also make baked goods healthier, and stay fresher, thanks to a new procedure which transforms them into an innovative fat-free flour.

The new technique is currently being tested at the University of Catania and results are encouraging.

At the moment, almost all bakers use fat, such as butter or margarine in their cooking.

But according to the research, half of this fat could be replaced by using flour obtained from orange rinds, seeds, and part of the pulp not used in juice-making.

Local bakers and pastry chefs in Acireale, near Catania, liked the new flour

Like Orange Fiber, the researchers obtain the raw materials they need from local juice makers. They wash the rinds to remove the bitter flavour, then dry, process and whiten what remains.

Salvatore Barbagallo, a professor of agriculture at the University of Catania, says the flour is "perfectly sustainable" and costs almost nothing to produce. It also has "no impact" on the taste and fragrance of food that contains it.

More stories from the BBC's Business Brain series looking at quirky or unusual business topics from around the world:

Elvis still earning a fortune 40 years after his death

Can ice cream vans stage a comeback?

The businesses capitalising on 24-hour sunlight

His researchers made 300kg of the flour and got local bakers in Acireale, near Catania, to try it out.

The cooks, known for being conservative about new ingredients, were all happy with the results and could taste no difference in their pastries.

The new flour is soluble

The researchers say they have found other uses for the flour, too.

It is soluble and can be added to drinks to provide health benefits. It could also be used by nutritionists and in medicine.

Natural fuel

Sicilian farmers have always used orange rinds as animal feed or fertiliser. But oranges can be a precious source of energy as well.

In Mussomeli, an ancient town near Caltanissetta in the middle of Sicily, orange waste products are used to make biogas which is turned into electricity.

The farm Nuova Scala used about 16,430 tonnes of rinds last year to produce 24,000 kWh of electricity.

Output varies depending on the amount of oranges produced, and the firm expects to get through 22,000 tonnes of orange waste in 2017.

Disposing of oranges after they have been juiced can be expensive

Of course, all of these projects depend on local fruit companies, which produce many thousands of tonnes of citrus by-products annually.

Salvatore Imbesi, who owns the producer AgrumiGel, says the rinds, seeds and other non-edible parts of the fruit are called "pastazzo", and he produces about 40,000 tonnes of it a year.

He says Sicily as a whole produces about 200,000 tonnes, although unofficial estimates suggest the real figure could be higher.

Producers have an incentive to re-use pastazzo, because disposal can be expensive. Mr Imbesi says that in Sicily the total cost of disposal can reach 16m euros every year, "six for the cost of the transport, and 10 for the disposal itself".

Some of Sicily's fruit is sold fresh, including its famous blood oranges, with the rest turned into juices.

In 2016, the amount juiced included some 140,000 tonnes of lemons, 100,000 tonnes of blonde oranges, 100,000 tonnes of blood oranges, 20,000 tonnes of green mandarins and 20,000 tonnes of matured mandarins.

Finally, thanks to the new crop of innovative solutions, the squeezed fruit are being turned from expensive waste into exciting products.

- Published14 July 2017

- Published25 April 2017

- Published24 November 2016