Bloodhound diary: Fast and scary

- Published

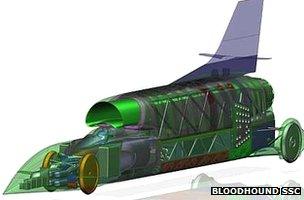

A British team is developing a car that will capable of reaching 1,000mph (1,610km/h).

Powered by a rocket bolted to a Eurofighter-Typhoon jet engine, the Bloodhound SSC (SuperSonic Car), external vehicle will mount an assault on the land speed record.

Wing Commander Green is writing a diary for the BBC News website about his experiences working on the Bloodhound project and the team's efforts to inspire national interest in science and engineering.

What's the fastest and scariest thing you've ever done? For me, they are two different events.

The fastest is, of course, driving Thrust SSC to the current World Land Speed Record of 763mph, way back in 1997.

The Cresta Run: Fast AND scary

The scariest thing, however, is an annual event that feels almost as fast - racing on the Cresta Run.

The Cresta Run is a 1,200m-long ice run in Switzerland, ridden head-first on a 30kg toboggan, at speeds of up to 75mph, with acceleration forces around 3g - three times that due to gravity - comparable to what Bloodhound will experience.

As the Royal Air Force Team Captain, and Royal Air Force Number One rider, I have to "go for it" ever year on the world's steepest ice run.

That's the scary bit. Worth the effort though: the Royal Air Force won the annual Inter-Services Championship again - fourth time in a row - which is a great way to start 2012.

With that excitement behind us, I have a feeling that this is going to be a great year for the Engineering Adventure, external that is Project Bloodhound.

Twenty-twelve is the build year for Bloodhound and it's amazing just how much is going on. All of the primary structure (that's the chassis to you and me) is now being manufactured. The rear chassis, external, currently with Hampson Industries and being supported by four other companies, will weigh just over one tonne when it's finished, but will take some six tonnes of raw materials to manufacture.

Much of the car will be steel and aluminium. Whilst we are using a lot of carbon fibre at the front of the car, the metal structures are ideal to withstand the huge heat and vibration from the jet and rocket engines at the back end, and the massive abrasion of the desert dust on the underside. Number of rivets to hold it all together? Current estimate is over 20,000.

20,000 rivets in close formation

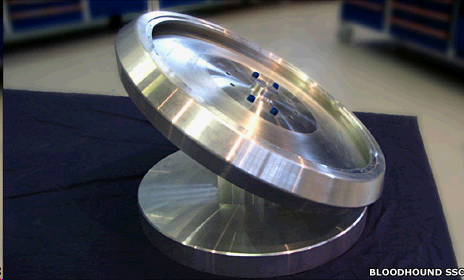

The wheels should be fairly straightforward, but nothing is simple when you're planning to do 1,000mph. The solid desert wheels will spin at over 10,000RPM and will have to endure 50,000g at the wheel rim. These high-speed wheels will be forged from solid aluminium, using low-risk techniques and materials that have worked well in the past. There are places where we can take some technical risk - and wheels isn't one of them!

Separately, we will need a set of "slow speed" (250mph) wheels with tyres, to allow us to test the car on a UK runway next year, before we set off for South Africa. There are 10 companies involved in the design and build of the wheels, and in a curious twist, we're shipping the runway tyres from South Africa for the UK runs.

The Falcon rocket testing is going to be one of the big developments of this year. To give you an idea of the complexity, we now have 40 companies just supporting the rocket programme.

The test schedule over the next few months involves first testing the whole system with de-ionised water, to check that we have no leaks. There are bound to be some - it's a new system.

The Bloodhound wheel: We know this works

Once they are sorted out, we'll move on to HTP (High Test Peroxide, at 87% concentration), which is pumped into the rocket motor at about 20 litres per second and 76 times higher than atmospheric pressure - which is why we need the Cosworth Formula 1 engine to provide 700 horsepower for the pump. This will be the first use of the X-Trac gearbox, which is itself a work of art.

Then we'll move on to the "real thing" - the hybrid firings, building the thrust up to the full 110,000 Newtons (25,000lbf). We can't announce the test locations just yet but, as Bloodhound project director Richard Noble observed recently, we won't need to - you'll hear it!

As you can see, we are getting terrific support from UK firms. The UK has the second-largest aerospace industry and the largest motorsport industry in the world, so it's a great resource for us.

A number of companies are jumping at the chance to do something this exciting, as well as leaving a legacy behind in the form of our education programme, external.

With nearly 5,000 schools and colleges signed up now, and more joining all the time, we really do have the chance to inspire the next generation, and to make a real difference to the UK's future engineering and science capability. Now we just have the build the car...

Last month, we launched a series of "Design and Make" packages, to give companies a discrete chunk of car to complete the detailed design and manufacture. The packages are outlined in our latest Bloodhound TV episode, external, filmed at the Autosport International Show last month.

One area where we can use some cutting-edge new technology is in the manufacturing process. Additive Layer Manufacturing, or ALM, gives us the option to "build" components. We can now make incredibly complex shapes - including ones that cannot be machined by normal means - and reduce waste to virtually zero. With even schools now getting access to 3D printers, this is definitely a technology of the future - and we're using it right now.

ALM involves printing parts for the car

In addition to the great support we're getting from industry and from our product sponsors, external, the public support continues to be outstanding.

Access to the Bloodhound website regularly hits 10,000 pages per day, and we are now being followed in 215 countries (I didn't even know there were that many).

Since we launched the project in 2008, the public have been getting behind it in ever-increasing numbers.

We have also topped 10,000 names on the tail fin of the car - but there's plenty of room for more. Follow the fin link, external to have your name (and better still your kids' names) travelling at 1,000mph one day soon.

Your name here...

- Published20 January 2012

- Published19 December 2011

- Published11 November 2011

- Published10 September 2011

- Published18 May 2011

- Published26 April 2011

- Published5 March 2011

- Published7 February 2011

- Published21 November 2010

- Published13 November 2010