Bloodhound Diary: A car festooned with sensors

- Published

A British team is developing a car that will be capable of reaching 1,000mph (1,610km/h). Powered by a rocket bolted to a Eurofighter-Typhoon jet engine, the vehicle will mount an assault on the world land speed record. Bloodhound will be run on Hakskeen Pan in Northern Cape, South Africa, in 2015 and 2016.

Wing Commander Andy Green, the current world land-speed record holder, is writing a diary for BBC News about his experiences working on the Bloodhound project and the team's efforts to inspire national interest in science and engineering.

"Data is key to pushing the boundaries - work out what you need and build it in from the start."

That was the advice we got from former Nasa astronaut Neil Armstrong, external when he visited the Bloodhound Technical Centre back in 2010.

Knowledge is power... back in 1997

This was very much our plan, but it was great to hear it confirmed by the first man to walk on the Moon. The reality seemed a long way off at the time, but suddenly it's here and we're building the sensors into Bloodhound SSC.

The plan for the whole car involves around 400 high-speed sensors, measuring everything from air pressure (in over 100 places, to validate our airflow modelling), through to structural loads, and even my heart rate while I'm driving at 1,000mph (I voted against this one, but I lost).

Each one of these sensors will be recorded at 500 Hertz (500 times a second), so we can analyse the data in incredible detail.

At peak speed in Bloodhound SSC, the air will be tearing past my "office window" at 450m/s, so working out what happens on each run will be vital. It was this sort of approach that got Neil to the Moon in 1969.

Our previous world record, back in 1997 when Thrust SSC went supersonic, was the first time that this sort of data-intensive approach had been used for record breaking.

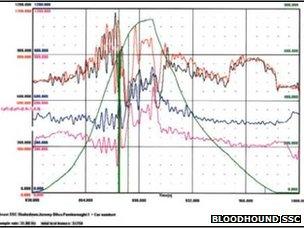

Supersonic data: Thrust SSC speed and wheel loads

The technology was a bit more basic, with just over 100 sensors measuring temperatures, pressures and loads at only 80 Hertz, or less. Still, that was enough for us to be able to keep the car safely on the ground, and to set the first supersonic World Land Speed Record.

Data helps with more than just keeping the car on the ground. The straight line performance of the car - in other words, how fast it will actually go - can also be determined from the data.

Since this is the whole aim of the World Land Speed Record, it's important stuff. But it's more fundamental than that. Our performance expert Ron Ayers has spent over two decades analysing performance data from every available source, going back to the 1920s.

As a result, I believe he can predict more accurately than anyone alive just how fast a land speed car will go, and how long it will take to stop.

It's Ron's huge expertise, honed during the Thrust SSC project, which gives us the confidence that we can reach the astonish speed of 1,000mph.

His performance programme is based around a calculation spreadsheet 100 columns across and well over 1000 lines deep (yes, you did read that right, it's over 100 x 1000 = 100,000 cells in size). Have a look at our "Performance Curve" video, external to see how we can use the results.

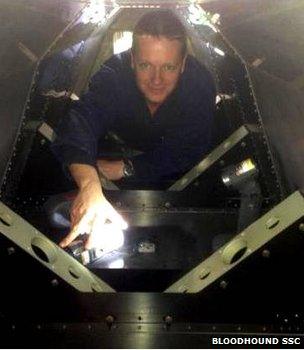

Strain gauges inside...

It's also based on real-world data, which makes it incredibly accurate, as I discovered. When we were record-breaking in Thrust SSC, Ron would give me very detailed figures about when to deploy the drag chutes and use the wheel brakes.

The car stopped exactly next to the turn-round crew, every time. No-one else had been able to do that before - it was simply amazing.

At this point you may be harbouring a small "so what?". Why does it matter where we stop?

The reason is in the rules for the World Land Speed Record, external. In order to set a record, you have to do two runs within 60 minutes. For Bloodhound, that means doing a racing pit-stop on something as complicated as the space shuttle, in a desert. Stopping a mile or two from the right place will cost time you just don't have, which then puts the crew under huge pressure to hurry, which isn't safe when you're getting ready to do 1,000mph (again).

Something as simple as stopping in the right place can make my job a lot safer.

However you look at it, the data is key - Neil Armstrong was right in so many ways. Even before we run the car, it's going to be hugely useful.

Our resident expert Mark, supervised by Steve from Straintek, has just finished fitting strain gauges inside the air intake, which will feed huge volumes of high-pressure air to our EJ200 jet engine.

...and out

This is a safety-critical part of the car, as it will be subject to huge pressures at 1,000mph (around 1.7 Bar/25 psi), which will exert a "bursting load" on the intake of around 29 tonnes.

If the intake bursts, then it will take the upper bodywork with it, which could then leave me… poorly placed. To make sure that the intake is up to the job, we're going to pressure-test it. As we inflate a huge air bag inside the intake, the strain gauges will measure the movement (or "strain") in the carbon fibre structure.

This will confirm that it can cope with the full 1,000mph load, and more. These strain gauges (and a huge number of others) will remain in place for the life of the car, so that we can monitor structural health at every stage of its life.

I've just been down to the Bloodhound Technical Centre to finalise the details of the drag parachute system, which will now undergoing final testing by Marlow Ropes and SES, before we fit the first system into the car.

While I was there, we had a delivery - the first desert wheel has arrived!

This 95kg disc will spin at around 10,300 times a minute (170 times/second) at 1,000 mph, subjecting it to loads of 50,000 times the force of gravity. Ouch.

The world's first 1,000mph wheel

Wheels are another safety-critical item, so of course we're now going to test this one, before Castle Precision finishes and delivers the rest. Rolls-Royce is going to spin the wheel on its old engine test rig and, as you would expect, we'll fit it with instruments.

This will validate all of our computer modelling and prove that the wheel will cope at over 1,000mph.

When the wheels are fitted and we start running the car, we'll be monitoring them on every run.

This will allow us to build up a picture of the normal "noise" that they generate running on the desert. By filtering this out, we can then listen for any changes or unusual "events" which might indicate a problem.

Yet again, data is key to reaching this spectacular speed. Every key part of the car has been tested, is being tested, or will be tested, and they'll all be monitored during every run of Bloodhound SSC.

There's a data mountain to build, and then to climb, over the next two years. It's a huge effort, but it's what will keep the car safe, so it's what we're going to do.

- Published28 January 2014

- Published25 December 2013

- Published19 December 2013

- Published4 July 2013

- Published13 May 2013

- Published3 October 2012

- Published7 February 2011

- Published5 March 2011

- Published13 November 2010