Graphene shows promise for bulletproof armour

- Published

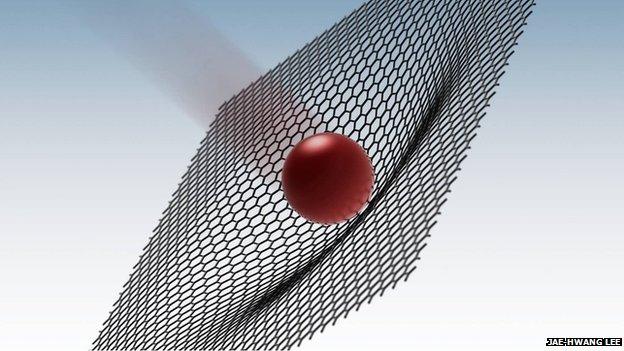

Caught in the net: Microbullets were fired at sheets of graphene

The "wonder material" graphene could be used to make bulletproof armour.

US researchers carried out miniature ballistic tests by firing tiny silica spheres at sheets of graphene.

In Science magazine, external, they report that atom-thick layers of this material can be stronger than steel when it comes to absorbing impacts.

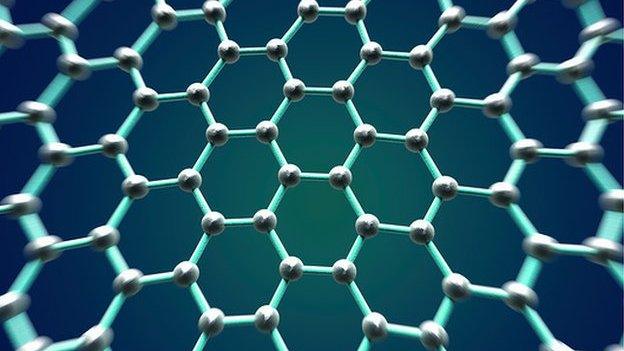

Graphene consists of a sheet of single atoms arranged in a honeycomb structure.

It is thin, strong, flexible and electrically conductive, and has the potential to transform electronics as well as other technologies.

Jae-Hwang Lee from the University of Massachusetts in Amherst and colleagues used lasers to observe the silica "microbullets" as they penetrated sheets of graphene between 10 and 100 layers thick.

They compared the kinetic energy of the spheres before and after they pierced the graphene sheets.

Observations using an electron microscope revealed that graphene dissipates energy by stretching into a cone shape and then cracking in various directions.

The mini-ballistic tests showed that graphene's extraordinary strength, elasticity and stiffness allowed it to absorb between eight and 10 times the impacts that steel can withstand.

However, the way in which graphene sheets responded to the microbullet also resulted in a wider impact hole - which could be a potential disadvantage.

Jae-Hwang Lee's team proposes that combining graphene with one or more additional materials to form a composite could prevent the cracking and solve this problem.

In 2010, Manchester University, UK, researchers Andre Geim and Konstantin Novoselov shared the Nobel Prize in Physics for their discovery of graphene.

They published details of their advance in the academic journal Science in 2004.

Another study published in Nature this week revealed that graphene sheets allow proton particles to pass through them, a property that could improve the efficiency of hydrogen fuel cells.

- Published22 April 2014

- Published12 October 2012

- Published15 January 2013

- Published20 November 2013