Bloodhound supersonic car gets its 'feathers'

- Published

It will soon be time for a paint job and the emplacement of tens of thousands of fans' names

The tailfin. It's one of the most iconic features on the Bloodhound Super-Sonic Car, external (SSC), not least because it'll carry the names of all the project's thousands of fans who've contributed to its funding.

But the fin is also arguably one of the most safety-critical aerodynamic surfaces on the vehicle.

It's essential to keeping Bloodhound SSC on a straight line as it races across the dried-out lake bed of Hakskeen Pan in South Africa to try to break the land speed record.

At 1,000mph, the big vertical stabiliser on the top edge of the rear of the car will be driver Andy Green's best friend.

"Like a dart, with the heavy lump at the front, it's the feathers at the back that keep the dart straight, and you need to create exactly the same effect at high speed in a transonic, supersonic car," he explains.

"At that speed, there is almost no wheel grip. The wheels will be penetrating the surface of the desert by perhaps two or three millimetres.

"My wheel grip will be less than running a slick-tyred car on ice. At supersonic speeds, all of the grip is aerodynamic grip; it's like flying a jet fighter."

The tailfin measures roughly 2.5m by 1.8m. Video cameras will look down the length of the car

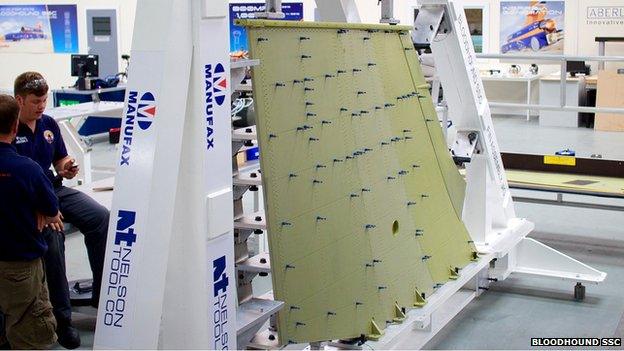

This week, at the Bloodhound Technical Centre in Bristol, Wing Commander Green has seen his RAF colleagues complete the manufacture of the tailfin.

Because the structure is identical to one you'd find on a fighter, it's the engineers from 71 Squadron (Inspection and Repair) who've been asked to build it.

The aluminium fin comprises 139 major parts.

Its key internal elements are five long vertical spars that take most of the loading. These are separated by shorter struts, or intercostals. The entire frame is then covered with a curved skin.

Everything has been hand-crafted by 71 Squadron, right down to the 10,000 or so rivet holes. And each of those holes has been opened in stages, deburred (cleaned of any sharp edges) and counter-sunk. It's been a painstaking process.

Indeed, the team has assembled and disassembled the whole structure several times on its laser-aligned rig to be sure of finding the perfect fit.

Says Bloodhound's tailfin lead, Terry Godsmark: "I was in the RAF for 20 years, and the guys here from 71 Squadron will confirm this: A lot of the time you work to manuals, and if you need to change something or fix something, there's a set process.

"But in this case, we don't have that because we're building a prototype, a one of a kind.

"It's a jigsaw and we always knew there would be a bit of up-down, up-down, as we sussed out all the glitches."

And colleague Mark Robinson adds: "Bloodhound is not like a Ford Mondeo where you can churn them out because you've produced so many of them already. Bloodhound is a one-off, and it will only ever be a one-off."

Sgt Matt Bradley (71 Squadron) and Gary Pitney (GP Panelcraft) shape the tailfin's skin

The internal skeleton is made up of vertical spars and horizontal intercostals

Robinson's job is to install all of the internal strain gauges, accelerometers and pressure sensors (a few cameras, too). Their data will help Bloodhound's designers understand how the fin is working as Andy Green takes the car ever faster, through the sound barrier and beyond.

Those who've been following the project from the outset will have noticed the fin change its appearance over time.

In early concept drawings, the stabiliser was envisioned as a small vestigial affair with T-mounted horizontal winglets. As the project has moved deeper into the design, the fin has grown and those winglets have been moved down into a cruciform configuration. There's also now a long strake running ahead of the fin.

All this has been necessary because the car has got heavier and its centre of gravity has moved backwards.

A bigger, more performant fin is now required to reposition the centre of aerodynamic pressure and maintain the desired yaw static margin - essentially the vehicle's dart-like quality.

Andy Green: "I am looking for a crispness of control"

Nonetheless, some fine tuning will be required when Andy Green starts running the car in South Africa.

He'll begin by going "slowly", say 300mph, before gradually upping the ante to close on the sound barrier.

On some runs, he'll twitch the steering wheel to see how the positioning of the car changes.

Does it step straight back, or does it continue to step out, and increasingly so?

The intention is to find a sweetspot where Bloodhound is neither too stable nor so unstable that all Andy Green's inputs are ignored by the car.

He will want small movements on the steering to give him small responses.

Fine-tuning may involve putting some lead weights at the front of the vehicle.

"We'll go step by step, proving that we have that positive yaw static margin - or in other words, the heavy bit of the dart is far enough in front of the tail feathers to make sure it sticks in the dartboard pointy-end first, every time."

The finished Bloodhound is still on course to roll out of the Bristol centre later this year. The car will be run across two campaigns in South Africa - the first to break the existing land speed record of 763mph (1227km/h), and the second to raise the new mark to over 1,000mph (1,610km/h).

Early design iterations envisaged a smaller, "T-fin" configuration

- Published19 May 2015

- Published28 April 2015

- Published25 March 2015

- Published14 March 2015

- Published2 March 2015