'Smart leg' makes engineering prize shortlist

- Published

A bluetooth link and calibration software train the leg to match the patient's walk

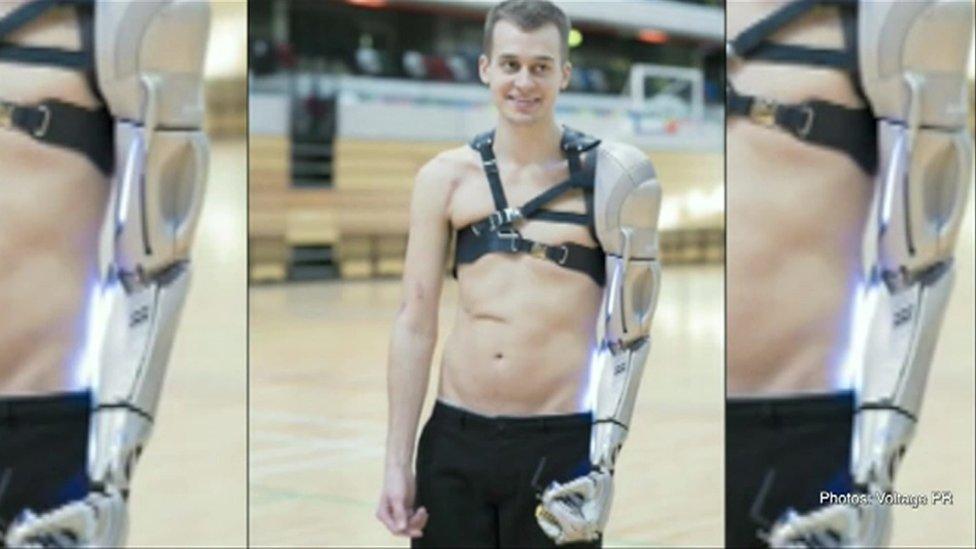

A "smart" prosthetic leg is one of three finalists for the MacRobert Award, a major UK engineering prize.

Made by Basingstoke firm Blatchford, the Linx Limb uses a network of sensors to adapt to changing conditions by adjusting its robotic knee and foot.

Also on the shortlist are Jaguar Land Rover, for building its own innovative engines, and Siemens Magnet Technology, for pushing the boundaries of MRI scanning.

The shortlist was announced on Monday, external.

The MacRobert Award, organised annually since 1969 by the Royal Academy of Engineering, will be presented for 2016 at a dinner on 23 June.

Each of the three nominees would "have a positive impact on millions of people and bolster the UK economy", said the chair of the judging panel Dame Sue Ion.

"It's often said that Britain doesn't make anything anymore, but these three companies are proof that the opposite is true, and testament to the world-leading engineering innovation that happens here in the UK," Dame Sue said.

"Each of this year's finalists has taken a different approach to innovation - from sustained incremental improvements to starting from scratch."

Prophetic prosthetic

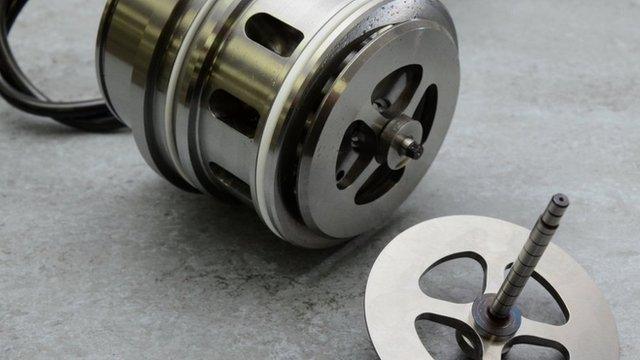

The Linx system is the first ever prosthetic limb with integrated, robotic control of the knee and foot. The parts work together much like those of a human leg.

For example, it senses when the wearer comes to a standstill and locks up, allowing the person to relax.

The limb has robotic ankle and knee joints which 'talk' to each other

When a patient is first fitted with the Linx, the calibration process is streamlined by software which records data about the patient's walking style via a Bluetooth connection.

The prosthetic is expensive, but could save money in the long run by minimising secondary problems such as back pain or falls.

"Blatchford has achieved a huge leap forward in making the knee and ankle joints work together as an integrated system, enabling it to adapt immediately to both the actions of the wearer and changes in the environment," said Dr Frances Saunders, one of the MacRobert Award judges.

Magnetic marvel

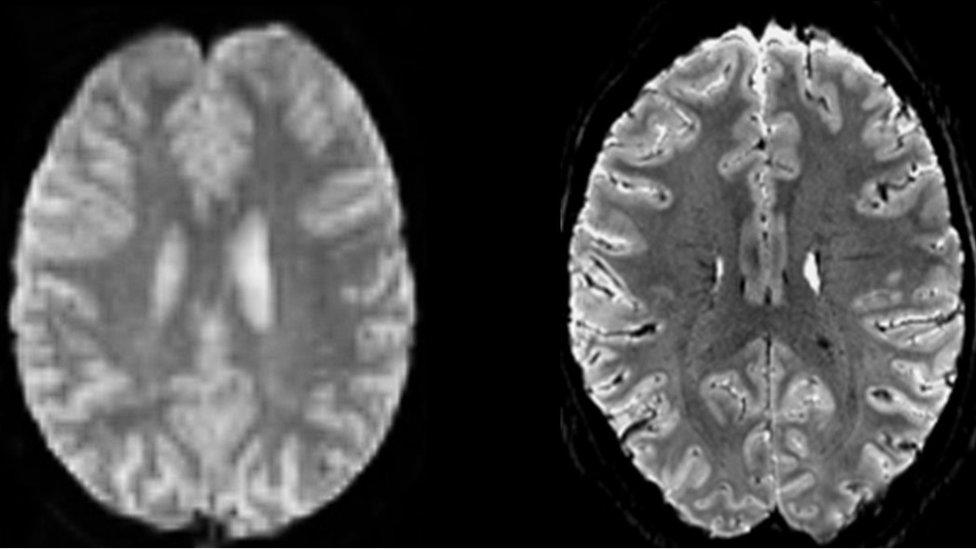

Siemens Magnet Technology, headquartered in Oxfordshire, developed the world's first seven-Tesla (7T) MRI scanner for clinical and research applications. This figure quantifies the strength of the magnetic field used to peek inside the body; the previous standard was 3T.

That boost in power delivers much clearer pictures, improving the accuracy of scientific research as well as making diagnoses, from Alzheimer's to multiple sclerosis, much more sensitive.

The boosted magnetic field yields much clearer images

In fact, SMT's "Magnetom Terra" scanner is expressly aimed at satisfying the needs of both clinicians and neuroscience researchers - a combination that previous technology has not managed.

The machine uses hundreds of kilometres of super-cooled, super-conducting wire to create a magnetic field 140,000 times stronger than the Earth's.

"The Siemens team made a radical change from conventional wisdom in the development of the 7T and have achieved a step change in the manufacturability, reliability, performance and cost of MRI magnets," said Prof David Delpy, another of the award judges.

In-house ingenuity

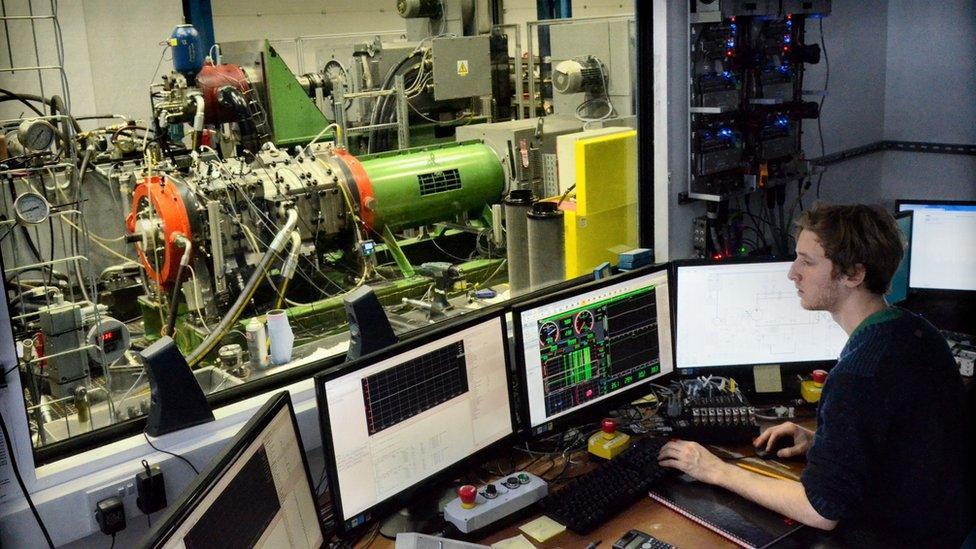

The Ingenium series of engines is the result of a big decision taken by Jaguar Land Rover in 2011: to invest £1.5bn per year for five years in new product development - with the aim of becoming self-sufficient in the design and building of its engines.

The results are lighter and greener than equivalent engines available today.

They are manufactured in a facility outside Wolverhampton that was built from scratch, starting in 2012.

MacRobert award judge Prof Gordon Masterton said: "The company has developed a world-leading facility of which Britain should be extremely proud. The ambition behind the decision to develop and manufacture their own engines cannot be underestimated - but it took world-class engineering talent to make that dream a reality."

- Published31 March 2016

- Published17 July 2015

- Published20 May 2015