Bloodhound Diary: Super-track for supercar

- Published

A British team is developing a car that will be capable of reaching 1,000mph (1,610km/h). Powered by a rocket bolted to a Eurofighter-Typhoon jet engine, the vehicle will first mount an assault on the world land speed record (763mph; 1,228km/h). Bloodhound, external should start running on Hakskeen Pan in Northern Cape, South Africa, in 2017.

With just one year - 365 days - to go until we'll be running Bloodhound SSC on the desert in South Africa, work continues to get the Car ready.

This seemed like a perfect time to inspect our desert track in South Africa, and to take a moment to celebrate the amazing achievement of the team which has prepared the best straight-line race track ever.

To build the excitement a little, we got them to spell out "365" on the desert, as a message to the world that Bloodhound is coming.

As far as the eye can see

When I first saw the surface of Hakskeen Pan, in the Northern Cape of South Africa, over seven years ago, two things were immediately obvious.

The first was that the hard, smooth clay pan surface could be the best land speed record track ever.

The second was that it would take a truly huge effort to clear the layer of stones that covered most of the 20 million sq m that we would need.

The Northern Cape Provincial Government very bravely agreed to take this immense task on and, seven years later, the results are just astonishing.

With work now all but complete, we went from one end to the other, over 12 miles (20km) away.

Thank you

As we raced along, all we could see was a perfectly smooth and stone-free surface, as far as the eye could see.

The track team of over 300 people has worked away for the past seven years, clearing an area equivalent to a wide road from London to Moscow.

They have prised around 16,000 tonnes of stones (over 50 tonnes per person!) out of the surface to leave the most incredible track surface behind, ready for Bloodhound to arrive next year.

The track team has hand-cleared the largest area on earth ever prepared for a motorsport event. We felt this should be formally recognised, so we contacted the Fédération Internationale de l'Automobile (FIA).

I was thrilled by the response: while the FIA President Jean Todt was unable to join us personally for the celebration, he sent the track team a very warm video message, external of congratulations.

The Bloodhound South Africa helmet

His message highlighted the essential contribution that the Northern Cape team has made to Bloodhound, and he told the workers that "the credit will be shared with you" for everything that Bloodhound achieves. Absolutely right.

In addition, the President of the FIA's Land Speed Record Commission, Dennis Dean, flew half way round the world to represent the FIA and to thank the track team personally.

Dennis presented every member of the team with a certificate of recognition from the FIA, and Bloodhound gave each person a medal to thank them for their unique achievement.

We were also joined by the Premier of the Provincial Government, along with several of her cabinet, and the whole event was covered live on national TV in South Africa.

A great day out for a great bunch of people.

Being back in South Africa also gave me a chance to meet up with Dirk Coetzee.

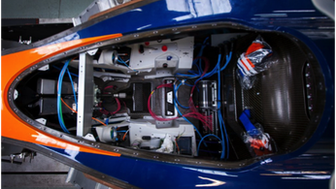

Main fuel tank

Dirk is the young South African who won our design competition to paint one of the Arai helmets that I will be wearing when I drive Bloodhound SSC. He proudly presented me with the finished article, external, resplendent in its Northern Cape sunrise orange, with the twin flags of South Africa and the UK, and (very aptly) an outline of the fastest local antelope, the Gemsbock. It's a real work of art.

Meanwhile, work in Bristol carries on, getting the car ready for record-breaking speeds next year.

The car has been stripped down, separating the 3,500-odd bespoke parts that make up Bloodhound SSC.

Each one is being carefully inspected, before being prepared for reassembly - the final build before running the car.

Each component and system will also be tested to check that it works as advertised. One of the first bits to undergo an end-to-end test will be the fuel system, which is being installed in the rear lower-chassis.

Cold enough for you?

The fuel system has a main tank (400 litres of Jet-A), which provides more than enough fuel for a full-power run.

However, we also need to allow extra fuel for jet engine warm-up and cool down, plus a reserve in case there is a delay before a run.

The main fuel tank already fills the space available for it, so we've added another two 100-litre auxiliary tanks, in the narrow spaces behind the main tank, just in case.

The three tanks will be connected together, with pumps to feed the fuel to the main tank and then into the EJ200 jet engine.

We'll take the whole system down to our UK test facility at Newquay Aerohub at the end of this year, for leak and function testing. After that, the fuel system's next job will be to feed a live and screaming jet engine, when the car fires up for the first time next Summer. Can't wait.

There was clear evidence the other day that we're now into final assembly, when a tank of liquid nitrogen turned up at the Bloodhound Technical Centre in Bristol.

Supersonic dust proofing

The tolerances for some of the components, such as the wheel bearing carriers for the suspension uprights, is so small that they can only be assembled when they are extremely cold (in this case, liquid nitrogen is below minus 195C).

Once each carrier goes into its upright and warms up again, it won't be coming out again. This really is the final build.

The cockpit monocoque has been hoisted up into the air, so that the titanium floor can be fitted to the underside and trimmed to its final size.

When the car travels across Hakskeen Pan at supersonic speeds, the shockwaves around the wheels will rip up the surface, creating a supersonic dust storm immediately behind the wheel.

Over the course of several weeks of testing, this supersonic "sand blasting" would start to wear away the underside of the car, just as it did on Thrust SSC, back in 1997.

Fancy a job?

The titanium floor panel is hard enough to survive this extreme environment, so that's one less thing to worry about.

One thing we haven't started work on yet is refining the cockpit displays and controls. We are still looking to recruit a couple of key people for the team, including a software engineer to look after the cockpit.

If you know anyone with the right skills, external who might like to join us for this unique once-in-a-lifetime Engineering Adventure, please do get in touch.

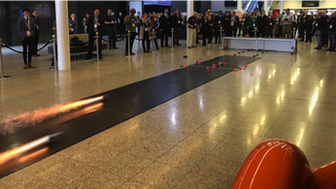

Bloodhound continues to draw young people in to the fascinating world of science and technology. In advance of the car's arrival at Newquay next Summer, the Royal Cornwall Museum ran a Bloodhound experience over the past few of months.

The most fun you can have indoors

To the museum's surprise and delight, the "Bloodhound Effect" has doubled the number of schools visiting the museum, compared with this time last year.

I went down there a few weeks ago, to talk about next year's testing and record-breaking plans, and saw a very excited group of youngsters building their own rocket cars.

Talking of rocket cars, if you haven't put your name down for a free rocket car kit for next year's competition (first prize - the chance to see Bloodhound SSC run in South Africa), then you have until the end of November. Book now to avoid disappointment!, external

- Published13 October 2016

- Published26 September 2016

- Published29 July 2016