Nepal brick kilns rebuilt after quake become cleaner

- Published

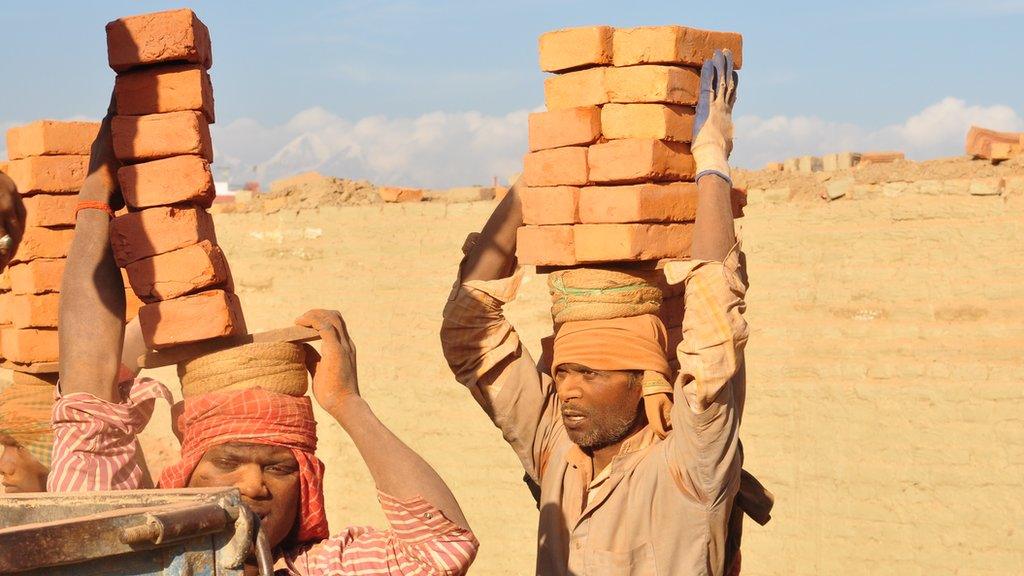

Workers carrying bricks at one of the kilns that is now significantly cleaner

Hundreds of coal-burning brick kilns are a major source of pollution in Nepal - but after a devastating earthquake two years ago, some are being rebuilt with new technology which promises a cleaner future.

Ram Kaji Awale was at his brick factory when the 7.8 magnitude earthquake struck Kathmandu on 25 April, 2015.

The 20-metre-high chimney of the brick kiln came down and the oven was completely destroyed.

"We managed to save all but one worker from the oven on that day," Mr Awale says.

More than 9,000 people died because of the quake that hit central Nepal and many old buildings were destroyed in Kathmandu, including nearly all of the brick kilns in the valley.

Workers pouring coal into the oven of the improved kiln

After the disaster, Mr Awale decided to rebuild his brick kiln with improved technology.

Traditional brick kilns run using old-style technology, with limited air passages in the oven.

That means coal is not burnt efficiently, so that large amounts of soot and other polluting particles are emitted from the chimney.

The new oven now has several air passages with fans installed in them so that there is plenty of air to burn the coal efficiently, creating significantly less polluting smoke.

"The new technology has not only stopped sending out thick black smoke," says Mr Awale, pointing at the stack, which now billows whitish smoke. "It has also increased our brick production by 25%."

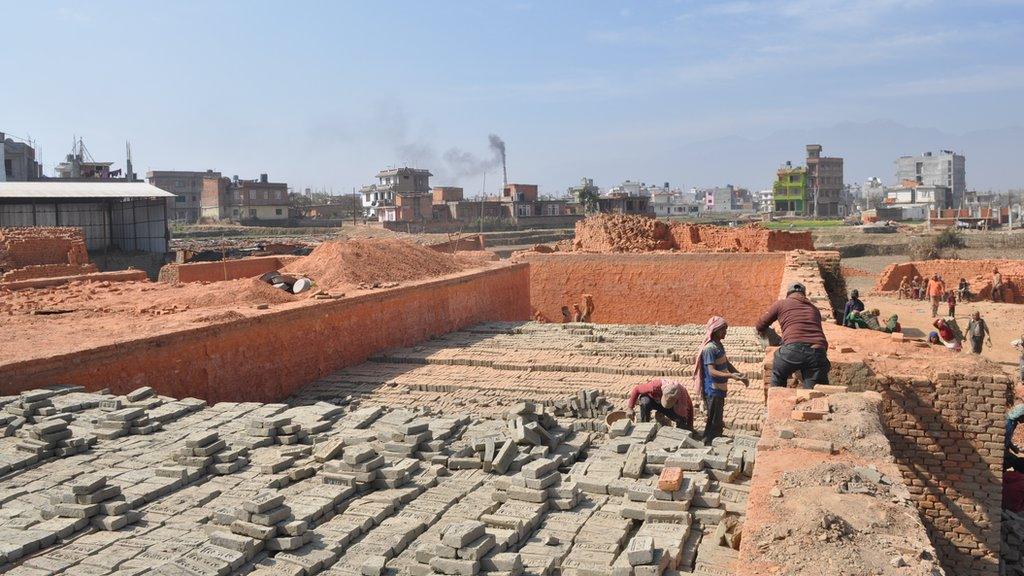

Piled up bricks near an improved kiln

Experts say the new design, known as zigzag technology, has been able to bring down pollution from the new brick kilns by around 60%.

"When this brick kiln ran with the old technology, it emitted more than 700 micrograms per cubic metres of particulate matter and now it is around 200," says Bidhya Pradhan, an atmospheric scientist with the International Centre for Integrated Mountain Development (ICIMOD), which helps brick kiln operators to switch over to cleaner technology.

"And if they are really good at it, they can also increase their energy efficiency by 50%."

So I Can Breathe

A week of coverage by BBC News looking at ways to cut air pollution.

Mr Awale says that more than the energy efficiency, it was the health factor that motivated him to make the change.

"Of course, it requires huge investment - almost double to what the previous technology required - but I was prepared for it because it is for my own and others' health," he says proudly.

"Everyone is happy about what I have done, our neighbours are also very happy about it."

Brick kiln with improved technology

His neighbours certainly seem happy.

"Before when we worked on our land like this, our hands were covered by black particles, same was the case with our feet when we went to our roof tops to dry clothes in the sun," says Ram Shova Bhandari, collecting vegetables from her kitchen garden just a hundred metres from the brick kiln.

"Now we have no such problem, the number of people suffering from coughs and other respiratory diseases too has gone down."

Workers in Mr Awale's brick kiln confirm that there are less soot particles coming out of the chimney but they say other issues remain.

"For us, more than the smoke from the chimney, it is the dust from bricks that causes problems because we inhale it while collecting the bricks and that problem has not changed," one worker in the factory says.

A long way to go

Despite cleaner air for residents around these factories, Kathmandu still remains one of the most polluted cities in the world. So far, only around 10 brick kilns in Kathmandu have adopted the new technology. That leaves around 90 brick kilns in Kathmandu valley that still use the old-style design.

"The challenge is not just to bring the change in them," says Ms Pradhan of ICIMOD, pointing at another brick kiln chimney billowing thick black smoke a couple of hundred metres away.

"There are also more than 800 brick kilns outside Kathmandu that still run with the old method. We need to roll out this new technology there as well."

With the Himalayas in the background, brick kilns still belch out smoke

The technology exists to make a difference. The question is whether the other brick kiln owners will be convinced to update their kilns.

While there are other significant sources of pollution in Kathmandu Valley, from vehicles to farm fires, there is a lot of construction still to be done in Kathmandu and nearby areas following the earthquake, so newer brick kilns could help build a cleaner future for the region.

- Published6 March 2017

- Published6 March 2017

- Published6 March 2017

- Published7 March 2017

- Published14 January 2019

- Published3 March 2017