RRS Sir David Attenborough's stern on the move

- Published

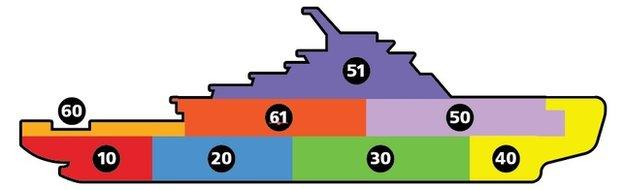

Block 10 will be added after the engines have been installed

A section of the UK's new polar research ship will get an early taste of the sea this week.

The rearmost portion of the Sir David Attenborough's stern is being moved from its production yard on Tyneside to Birkenhead where the rest of the hull is being built.

"Block 10", as it is known, will travel on a barge pulled by tugs.

The 900-tonne mass of steel will take just under a week to complete the trip around the UK.

It is likely to travel south through the English Channel rather than go "north-about" round Scotland. But the final decision will depend on tides and weather, says Linton Roberts, the managing director of Cammell Laird shipbuilders.

"If they come across the top via Pentland Firth and Cape Wrath and down inside the Western Isles, that's five days. If they go down the North Sea, through the English Channel and around Land's End and back up to us at Birkenhead - it's six-and-a-half days. So, going north-about is more efficient, but it's all down to the weather," he told BBC News.

The ship is built in blocks which are then joined together

The 128m-long RRS Sir David Attenborough has been commissioned to replace the UK's existing polar fleet - the RRS James Clark Ross and the RRS Ernest Shackleton.

The new vessel, which is costing £200m, will support British scientists working in the Antarctic and the Arctic.

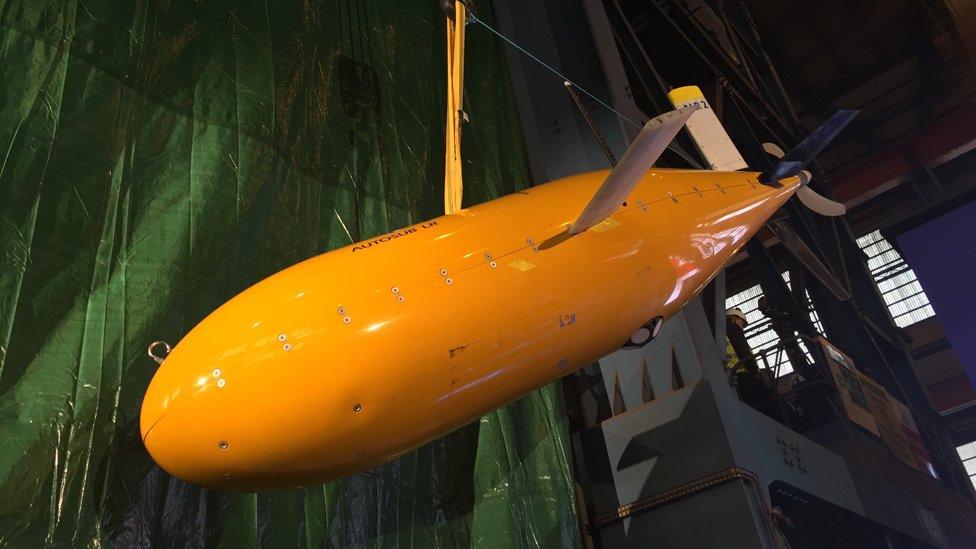

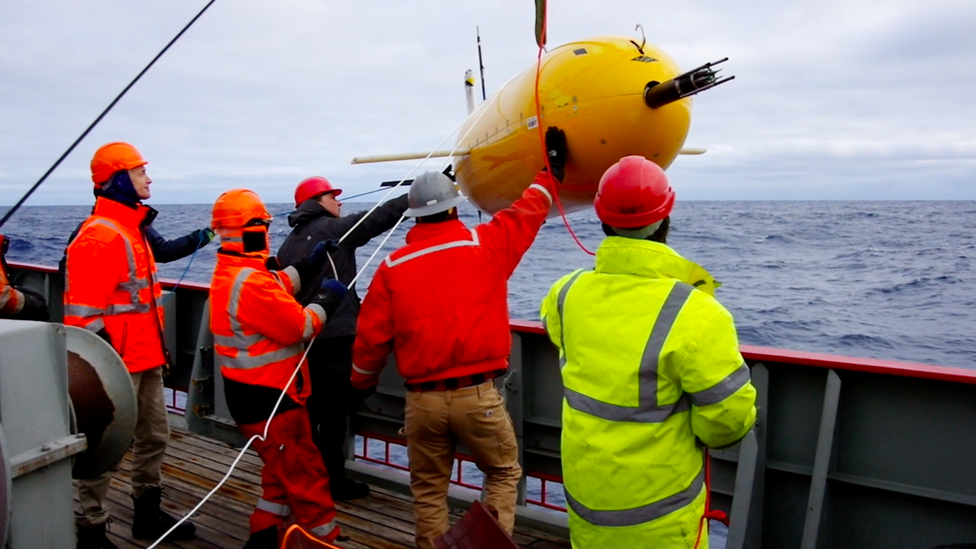

It will feature a big cargo hold, a helipad, cranes and onboard labs, and have the ability to deploy subs and other ocean survey and sampling gear.

Some of this equipment will go into the sea through an enclosed "moon pool", or "wet porch", inside the vessel.

Cammell Laird won the contract to construct the ship, external, which has been designed by Rolls-Royce. The schedule is tight and it chose to sub-contract Block 10 to A&P Tyne, which is based at Hebburn on the south bank of the Tyne River.

The pair worked together in similar fashion on the UK's new aircraft carrier, HMS Queen Elizabeth.

Artwork: The Attenborough will work both in the Arctic and the Antarctic

"This is precisely the kind of collaboration that can help rebuild the commercial shipbuilding industry and provide thousands of highly skilled jobs," said John Syvret, who is the CEO of both Cammell Laird and A&P Group, which owns A&P Tyne.

"What we are doing in fact is providing proof of concept, of the strategy outlined in Sir John Parker's National Shipbuilding Strategy report commissioned by UK Government.

"By investing in UK shipyards, and encouraging shipyards to work together, the UK can dramatically ramp up the number of ships it builds, converts and repairs, for the commercial and naval sectors at home and abroad."

Block 10, which is the equivalent weight of 71 London double decker buses and more than 23m long and 24m wide, is loaded on to the barge at Hebburn using self-propelled modular trailers.

The same procedure in reverse is then used get the hull segment on to the slipway at Birkenhead.

The rest of the hull is rapidly nearing completion. The engines that will drive the ship through the water are being installed at the moment. Once this work is done, Block 10 can be added.

"It's tremendously exciting but our reputation is built on delivering everything that people trust us with on time. And we're going to deliver this one on time, too," Mr Roberts told BBC News.

The Attenborough will take over the duties of the UK's existing polar fleet

Jonathan.Amos-INTERNET@bbc.co.uk, external and follow me on Twitter: @BBCAmos, external

- Published17 October 2016

- Published28 June 2017

- Published17 October 2016