Turf technology: Will pitch help England beat Uruguay?

- Published

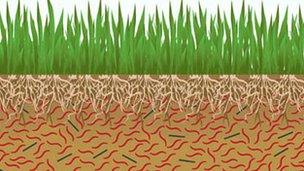

Could this kind of grass in Sao Paulo give England the edge against Uruguay?

After defeat to Italy, the stakes are high as England prepare to take on Uruguay in the World Cup. With desperate fans clinging to any sign of hope, could it be that Dutch carpet-manufacturing technology comes to England's rescue?

When England's players walk out on to the Arena de Sao Paulo pitch on Thursday for their qualifier against Uruguay, their studs will be sinking into familiar terrain.

It is that distinctive feel of the hybrid pitch - part polyethylene, part normal grass, blades that are 4% plastic and 96% as-nature-intended.

It was trail-blazed by Huddersfield Town in the mid-1990s, because they needed a pitch tough enough for both football and rugby. And the method has become turf's "third way" in the Premier League, a thoroughly English compromise.

It remains a relatively recent technology for the World Cup. Two stadiums tried hybrid pitches in South Africa in 2010, for the first time in the competition's history.

On Thursday England will be playing on Brazil's only hybrid pitch.

"This might offer that 0.001% of a difference," says David Saltman, of Pitchcare, external, who has been a groundsman for 25 years. "But that's what managers care about, because that can win them games."

Turf tech

Computer-guided injection machines worked their way methodically around the Arena de Sao Paulo last November - though from a distance they simply looked like two juddering mobile tents.

The machines were busy injecting more than 20 million plastic fibres into the soil.

In a painstaking process, polyethylene fibres - fake grass - were planted in a grid system, which broke the pitch down into 2cm (0.8in) by 2cm units.

The devices are like huge sewing machines, drawing on the same kind of technology used in the carpet-making industry.

David Nicholls of Dutch firm Desso explains how hybrid pitches are made

This is no coincidence, because the Dutch firm that specialises in this technique, Desso, is a carpet manufacturer.

Each machine cuts the plastic yarn into 40cm strips, which are "bobbed" in front of a needle. The needle catches the plastic at mid-point to create a loop, which is then plunged into the ground.

Once the plastic fibres are laid in this way, special sports grass seed is grown and established, so the two intertwine at root level. This is what is called a hybrid pitch.

It is a method born of frustration with other turf techniques.

Pitch perfect

English clubs had a brief flirtation with fully synthetic plastic pitches in the 1980s - but these were seen as too bouncy, prone to cause injuries, and offering an unfair advantage to the team that trained on them.

While many footballers favoured the feel of natural turf - which after all had sufficed for the game since its infancy - it was inconsistent, notoriously difficult to maintain and periodically led to "quagmire" pitches - the bete noire of managers on the losing side of an encounter.

The rebuilt Wembley stadium had perennial problems maintaining its natural turf, until it switched to a hybrid system in 2010. It is meant to offer the best of both worlds - a tough, durable pitch, and the feel and "play" of natural grass.

Desso has laid hybrid pitches for Manchester Untied (pictured), Arsenal, Manchester City and is currently working on Chelsea's

About two-thirds of Premier League pitches are now hybrid, fitted by Desso.

The main rival to this kind of turf technology is known as the "reinforced" pitch, developed by English firm Mansfield Sand.

This method involves adding polypropylene fibres. But the process takes place beneath the surface in what is known as the "rootzone", so no artificial blades are actually visible.

Newcastle United and Fulham both used this technology for their pitches.

"Most players would says hybrid pitches are a little bit harder," says turf veteran David Saltman - an assessment that Desso shares.

Before away games, managers will try and train on similar pitches to their opponents, Mr Saltman explains.

"For your Wengers or Fergies, top-end managers, the quality of the pitch will add an extra dimension to how they play."

Game on

In the run-up to the World Cup, Brazilian contractors worked intensely to make sure its pitches met strict Fifa regulations.

This work was hampered by public outcries over escalating costs, as well as the range of Brazil's climate.

Rigid polypropylene fibres and flexible elastane fibres (red) in Mansfield Sand's latest kind of reinforced pitch, known as Fibrelastic

In fact half of the 12 pitches prepared for Brazil's World Cup are of the old-fashioned natural turf variety.

The final itself on July 13 at Estadio do Maracana, Rio de Janeiro, will be held on natural grass.

All of the other pitches, except Sao Paulo, opted for the "reinforced" pitch technique.

Super-grass

So, will English players who are used to Premier League pitches have a slight advantage when they play against Uruguay on Sao Paulo's hybrid pitch?

"Look, when I was groundsman before a cup final," says Mr Saltman, who looked after Cardiff's Millennium Stadium, "every manager was intrigued by the pitch."

"They would come up to me and ask, 'How is the pitch going to perform?'. And they would often then incorporate this into their team talks, 'It's a greasy pitch today, try swinging some crosses in,' that sort of thing.

"We groundsmen used to be viewed as cloth cap-wearing blokes sitting in a tin can shed," Mr Saltman adds wryly. "Now people are starting to realise how much science is involved."

That science could make the small difference that lands England World Cup glory - or at least qualification to the next round.

- Published12 June 2014

- Published10 June 2014

- Published8 May 2014