Rise of the cheap and cheerful warehouse robot

- Published

- comments

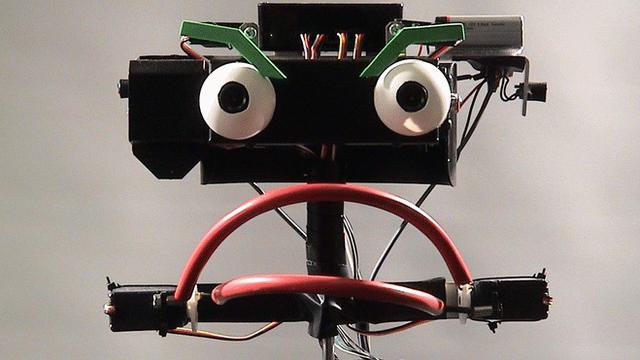

A Guidance Automation robot using University of Birmingham software navigates the warehouse

There's a bit of a dirty secret about robots in the workplace.

They're really expensive and more often than not you have to build the workplace around the robots rather than the staff.

But I've been to a Wiltshire warehouse to see prototype robots that are cheap and simple and can easily be dropped into an existing set-up.

Gompels is a company specialising in products for nurseries and care homes.

Customers order online and anything from teabags to nappies are sent out from the warehouse.

Like so many companies in logistics they're all about making continual improvements to the whole process.

At the moment, a team of human pickers roam the warehouse pulling together an order displayed on a smart phone on their arm.

Robots alongside humans

Working alongside the humans is a team of robots.

In appearance they look like an automated shopping trolley.

The robots also have an order list to fill from their own onboard smart phone.

To keep costs down the robots don't have arms or any sort of grabber.

Instead, they whiz to the location of the first item they need and then wait for a passing human to get it from the shelves and drop it into their basket. Then it's off to the next location.

The robot follows barcode stickers on the floor while scanning the path ahead to avoid obstacles like human staff

What Gompels and the robots are doing is improving the efficiency of the human pickers. If a human is walking past anyway, it takes no time to drop something into the robot's basket, but the overall impact is to make the warehouse just a little bit more productive.

For companies the big advantage is you don't have to build a new, robot friendly warehouse.

Put some barcodes on the floor that the robots can read so they know where they are and that's it. The robots are clever enough to cope with humans, boxes and even reporters getting in the way.

You can even tweak the software the human pickers rely on to make sure they end up going past as many robots as possible.

The Tracey brothers

The humans I spoke to didn't mind their new colleagues which have been made as human friendly as possible.

The small robot team have been named after the Tracey brothers from Thunderbirds and they've been fitted with a speaker that plays a mechanical engine noise.

Otherwise the robots were too silent and people kept tripping over them.

The software controlling all this has been created by the University of Birmingham and I watched Dr Nick Hawes clearly enjoying himself as he followed a robot round the warehouse getting everything it wanted. It was his first time seeing his creation working in the wild.

The Leicester company Guidance Automation, external built the robots and they're pleased with how the prototypes have done. So much so that a slimmer model will go on sale this month.

This is the future of robots. Something affordable that can cope with working alongside us. Perhaps not as exciting and impressive as those big robots you see on car production lines or massive, multimillion pound, highly automated warehouses, external.

But the do offer companies like Gompels a useful efficiency boost and a new competitive edge over their rivals.

- Published11 September 2015

- Published13 October 2015