Inside the UK's largest salt mine

- Published

While there have been storms aplenty in the UK this winter, the country has had five relatively mild winters in the past six years. It's not ideal for the rock salt suppliers whose product keeps Britain's roads clear of ice and snow - so how do they cope amid fickle weather?

Recall the winters of 2009 and 2010 - when the country was blanketed in snow and engulfed in transport turmoil as supplies of grit salt dwindled.

Salt mines and local councils were subsequently urged to boost their stocks, external. But a series of mild winters was to follow.

"If we were to have a very cold winter, we could supply all of our customers for every gritter to go out every day for two months," says Gordon Dunn, who is in charge of Winsford Mine owners Compass Minerals UK.

However, unpredictable conditions do not always make for good business.

"A salt business is very weather-dependent," says Mr Dunn, "so several years ago we started a records management business to take away the effects of the peaks and troughs of winter."

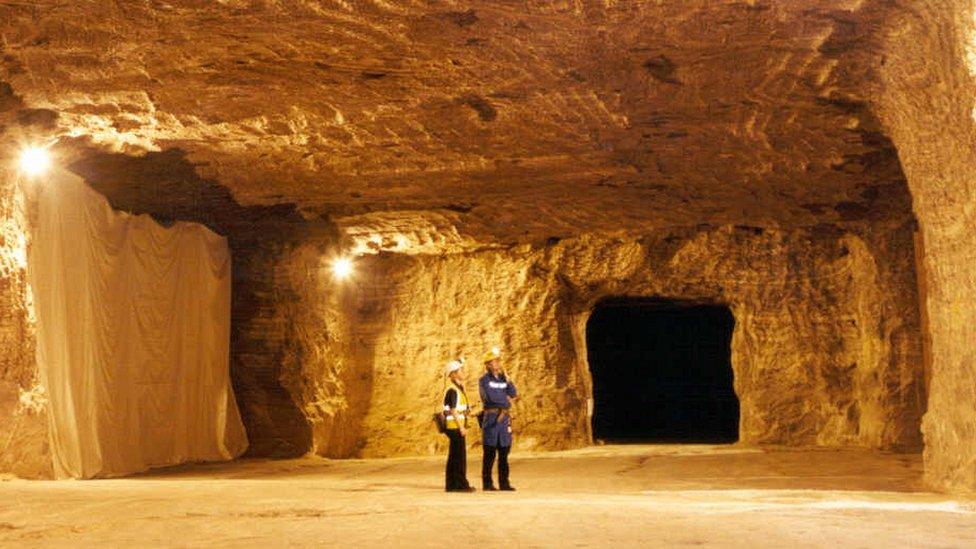

He adds that the Cheshire mine's naturally constant temperature makes it a useful storage location.

"Some police forces find it ideal but we also store for the National Archives."

About 2.2 million boxes - some of which include film archives and banks' records - are shelved in 32 large "rooms", with a couple extending to two floors.

Even Crossrail uses the mine's archive division, known as Deepstore, to keep rock samples from its route across London.

"If you could see the Deepstore business on the surface, it would look like a medium-sized industrial estate," says Mr Dunn.

But underground it feels like a suitable lair for a James Bond villain - and there's certainly room for a car chase in its dark, cavernous tunnels.

Rock salt can be tinged pink or brown although clear edible pieces are found occasionally

The mines are the legacy of the shallow salt marshes believed to have formed about 220 million years ago during the Triassic period, when what is now the British Isles was still attached to continental Europe.

"This whole area through the Cheshire basin and beyond - it goes across to Northern Ireland and further south - was a huge trapped sea that slowly evaporated, refilled and evaporated some 250 million years ago, leaving layers of rock salt," Mr Dunn explains.

In Cheshire, the Romans were the first to boil the substance bubbling up from natural brine pits. The term salary is derived from the Roman word salarius,, external which referred to the money allowed to soldiers for the purchase of salt.

The names of some of the county's towns - Middlewich, Northwich and Nantwich - also indicate the presence of salt, with "wich" possibly suggesting buildings by a salt-pit, external, according to the Oxford English Dictionary.

But in 1844, prospectors, who were looking for coal to heat saltpans, unintentionally struck even more rock salt at nearby Winsford.

A mine was soon opened, where buckets lowered miners who worked with the aid of explosives and picks.

While the technology has changed significantly over the years, the method remains fairly similar.

How rock salt is mined

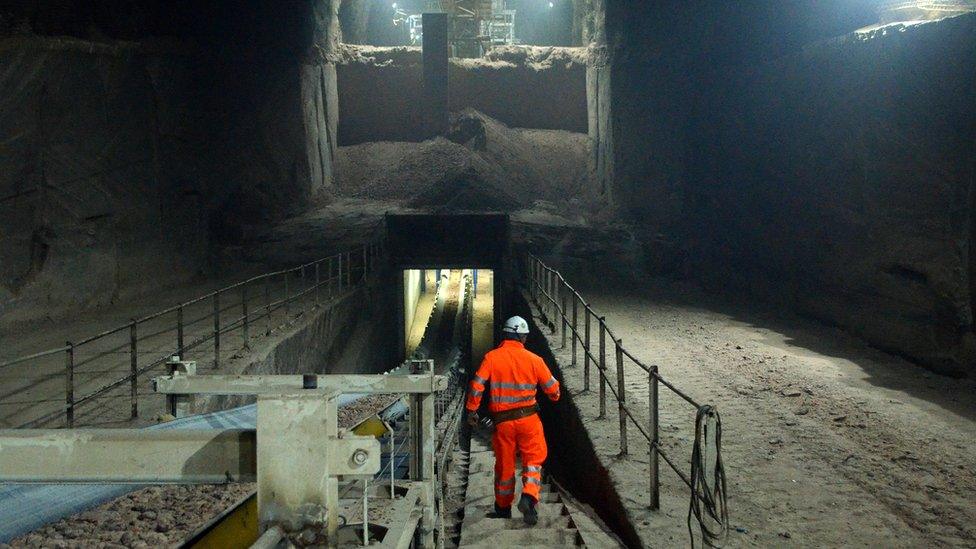

A continuous miner claws away rock salt, which then gets crushed before delivery

Machines, known as electric-driven continuous miners, claw out walls of salt

This leaves "rooms" or chambers with pillars of rock salt left behind to support the roof

Salt is loaded on to conveyor belts before being crushed and delivered to customers

"We leave 25% of the rock in situ and that holds the roof up," says Mr Dunn. "It's a very stable mine so every tunnel we've mined is still there - we have over 160 miles of tunnels.

"What you see underground is exactly the same as what goes on the road. There is a very small amount of an additive that stops it binding back together so it spreads more easily."

To prevent a repeat of previous travel chaos, Winsford Mine - the largest of the UK's three salt mines - has recently invested in more machinery to be used under the Cheshire Plain.

Most of its supplies are sold before the winter to clients including councils and Highways England, as they prepare for potential ice and snow.

The mine produces, on average, the equivalent of up to 15,000 tonnes - or 550 full tipper trucks - of salt each day. More than 500,000 tonnes are also stored above ground at the mine.

To put this in context, British demand in an average winter is about 1.5 million tonnes, although this can double in severe weather.

Mr Dunn says: "We have set ourselves up now to supply the UK's harshest winter."

Winsford Mine runs under Cheshire four miles east-to-west and three miles north-to-south

- Published3 November 2014

- Published26 August 2015

- Published5 June 2015