Coventry - is the UK's 'motor city' still driving forwards?

- Published

Coventry's car-making heyday remembered

The last Peugeot to be made at the company's Coventry plant rolled off the production line 10 years ago. It could have been the death knell for the city's automotive industry, but new technology is inspiring confidence once more in the UK's "motor city".

Ten years ago the mood in Coventry was sombre, certainly at the Peugeot plant, near Ryton, where production was ending.

Jim O'Boyle, union convenor and Peugeot worker for 20 years, said he watched the last vehicle coming off the track (production line).

"They were ripping up the track just behind it as the last car came off. It was terrible," he said.

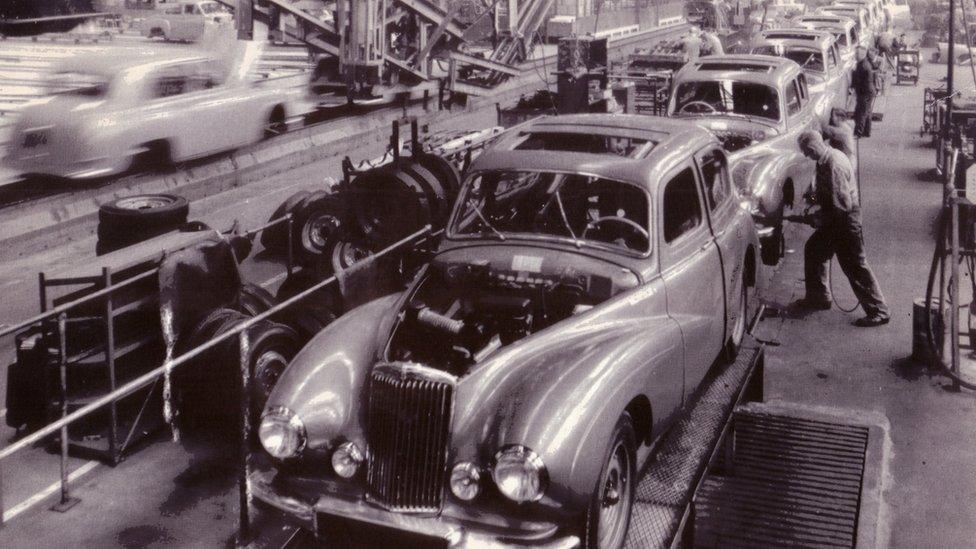

The Sunbeam Talbot 90 in production at Ryton, near Coventry, in 1950. Motorcar sales had taken off and Coventry was in a period of prosperity

These days he is the cabinet member for jobs and regeneration at the city council: "When I joined (Peugeot) I couldn't imagine ever doing anything else.

"Now I can't believe I was ever there."

Coventry's automotive heritage:

In 1950 there were 12 manufacturers - Alvis, Armstrong Siddeley, Daimler, Hillman, Humber, Jaguar, Lanchester, Lea-Francis, Singer, Standard, Sunbeam-Talbot and Triumph. The UK had the world's second largest car-making industry, producing 372,370 vehicles between 1962 and 1964, and was the world's leading car exporter.

Between 1959 and 1963 weekly earnings in the car industry in Coventry were 24% higher than the national industrial average. Women formed 37.9% of the workforce compared to 30.8% in the rest of the UK.

A rise in European and US manufacturing meant that by 1974 Coventry's car output had started to decline.

The city's top 15 employers axed almost half their combined labour force between 1975 and 1982, which by the end of the period translated to roughly 520 jobs a month.

By the mid-80s the two surviving plants were Browns Lane and Ryton, producing Jaguar, Daimler and Peugeot products. Unemployment had risen to 17% and Coventry band The Specials released Ghost Town. (Sources: Coventry Motorcar Heritage by Damien Kimberley and the Coventry Transport Museum)

Twenty-three years ago the RDM Group, on Humber Road, near Ryton, had a plant harnessing component parts for firms such as Jaguar Land Rover (JLR), Rolls-Royce and Bentley.

Now its employees, 80% of whom are engineers, are at the forefront of 21st Century engineering and design - one project, for example, involves creating software to enable cars to park themselves in garages.

The company is currently waiting for the council to agree to a trial, which the government is paying £20m towards, for autonomous vehicles in the city. Smaller trials have already been held down the M1 in Milton Keynes.

This driverless pod, produced by the RDM Group in Stoke, Coventry, could soon be picking you up at the railway station and taking you into town

"We are looking at how the cars communicate with the pods. For example, you could be travelling along in your Land Rover towards the city centre," marketing director Miles Garner said.

"The computer in the car will communicate with a pod. It will tell the pod it has two guests to pick up - and then your last half mile or so of the journey will be in the pods."

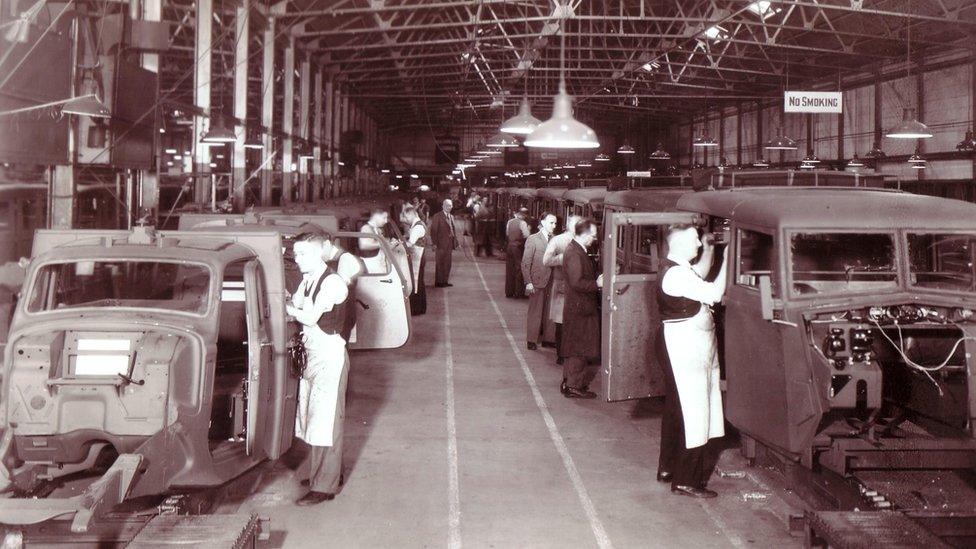

Humber production during World War Two. Would these workers have ever thought they could one day be driven around in an autonomous pod, produced on the same site?

Humber Road, as the name suggests, is the site where the Rootes Group once produced its Humber car.

"It's nice to be leading these technical drives where all the old car manufacturing used to be," he said.

Your two-seater driverless pod awaits

Not all the old car sites are still being used in the automotive trade.

Browns Lane, once home to Jaguar and Daimler and where car production ended in 2004, two years before Ryton closed, is due to become a 24-hour distribution centre for Amazon.

The former Peugeot plant was demolished and the site is now home to various companies and warehouses.

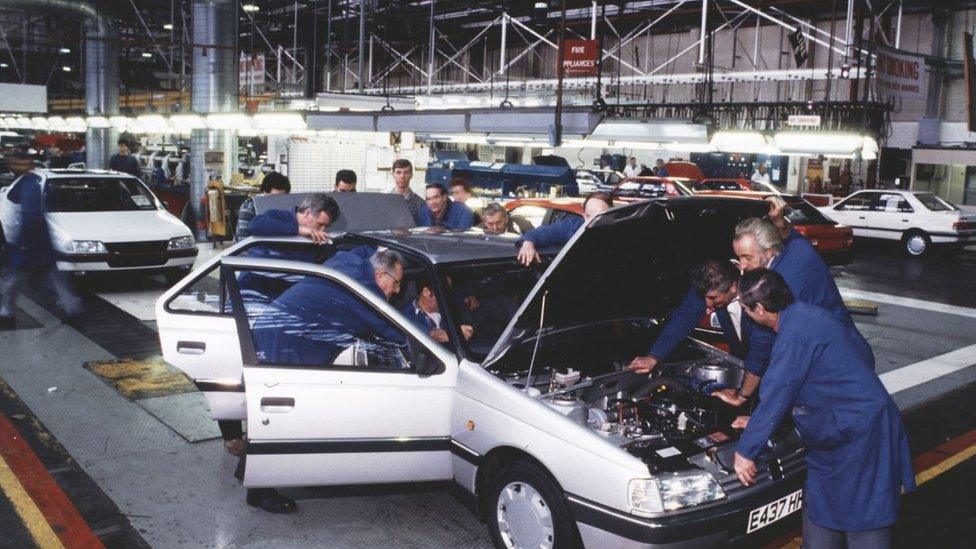

Peugeot 405 production at Ryton in 1987. The factory would shut 19 years later

Meanwhile JLR is expected to push ahead with its expansion into electric vehicles with a planned "global centre of excellence" for battery research.

Its Whitley site, two and half miles out of the city and the firm's global headquarters, is already earmarked for expansion but it is expected to need more space, with sites around the city's airport, in Baginton, being looked at.

Rootes production in the 1930s at Humber Road. Work had already begun in the city to get rid of the medieval roads to make way for the motorcar

Last month chief executive Dr Ralf Speth laid out a vision which could see 10,000 new jobs created in the West Midlands. Already the largest carmaker by volume, JLR would like to double production from 500,000 to one million cars a year.

The firm is expected to be working with Warwick Manufacturing Group, which is part of Warwick University, on the edge of the city.

Mr O'Boyle thinks this could bring manufacturing back to Coventry.

JLR's site in Whitley, Coventry, the firm's global HQ, has been earmarked for further investment

"The biggest change is the type of vehicles. Clean-air vehicles and electronic cars, that is a massive opportunity," he said.

"But we need new expertise and we are working with the Warwick Manufacturing Group and Warwick University to get that - that's where the future lies.

"Once the prototype is in place, you get your product in the showrooms, make them affordable and then you need the workforce to build them.

"Jaguar wants to do it in Coventry. We just need the infrastructure in place."

Top ten employers in Coventry - 2011. Source: Coventry City Council

1) Coventry City Council 15,617

2) University Hospital Coventry and Warwickshire 6,500

3) University of Warwick 6,000

4) Coventry University 4,600

5) Coventry & Warwickshire Partnership NHS Trust 3,500

6) Jaguar Cars Ltd 2,570

7) Barclays Bank Plc 2,400

=8) Royal Mail Group 2,000

=8 )Severn Trent Laboratories Limited and Severn Trent Centre 2,000

10) Admenta UK Plc (AAH Pharmaceuticals & Lloyds Pharmacy) 1,800

In Ansty, five miles northeast of the city, black cab producer the London Taxi Company is just about to move into its new 50,000 sq ft plant where it will produce its new vehicle, the all electric TX5.

The TX5 - London Taxi Company's first all electric cab. The firm's new 50,000 sq ft site in Ansty is due to open officially in spring 2017 and could employ up to 16,000 people if it takes on a third shift

The firm has outgrown its Holyhead Road premises in the city, where it started life in the 1920s producing car bodies for Jaguar, Rolls Royce and Bentley.

It currently employs more than 400 full-time people and company president Peter Johansen says that could go up to 1,600 if a third shift is introduced to produce the cabs. The firm hopes to have the capacity to produce 36,000 vehicles.

Various classic cars, some built in and around Coventry, used by Revival Cars in Humber Road for rentals

Chrysler Body Panels being put together at Ryton 1976. By then, the city was losing 520 motoring jobs per month

In his opinion, Coventry is still the UK's motoring centre, albeit with a larger surrounding area.

"I would actually say Coventry still eclipses all of the country - although you would include the wider area with Birmingham and firms south of Coventry into Warwickshire and along the M40 corridor," he said.

He cited firms such as Ricardo in Leamington Spa, Pro-Drive in Banbury, Aston Martin and other research and development firms in Gaydon plus the Warwick Manufacturing Group, as all contributing heavily to the progress in the automotive industry.

Penso, employing more than 200 people and which has been based at the airport for 12 years, focuses on design and engineering solutions for the automotive industry.

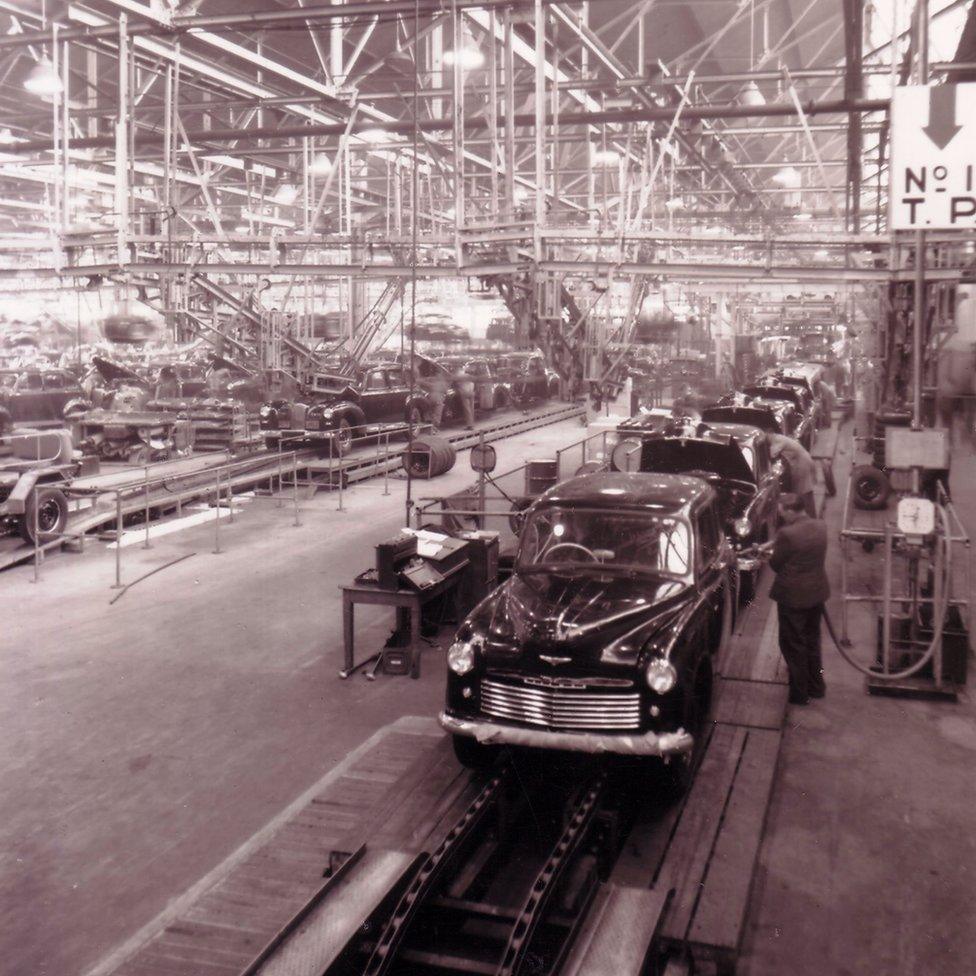

The Hillman Minx Production Line, Stoke, Coventry, c1935

With the Renewable Energy Directive, external in mind (all EU countries must ensure 10% of transport fuels be renewable by 2020) it works with new technology to reduce waste.

In Coventry Penso has a huge press making carbon fibre components and is notable that it, along with LTC, are the two firms producing London's black cabs (which are also sold all over the world).

Production at Ryton in the 1950s. The site was demolished after Peugeot left and is now home to various companies

The city council's crest features a phoenix rising out of the flames and represents the new Coventry rising out of the old (the city was heavily damaged by German bombers in November 1940).

The motto is apt for the city's industry, sales director Michael Collins said.

The Sunbeam Talbot 90 in production at Ryton, in 1950. The city became increasingly prosperous during the 50s and remained so for 20 years

"Out of adversity comes dynamic change. It was sad when Ryton closed but I think such things drive innovation."

The city's universities, Coventry and Warwick, lead the way with industrial design and companies like Penso are taking on apprentices to help out with a skills shortage, he added.

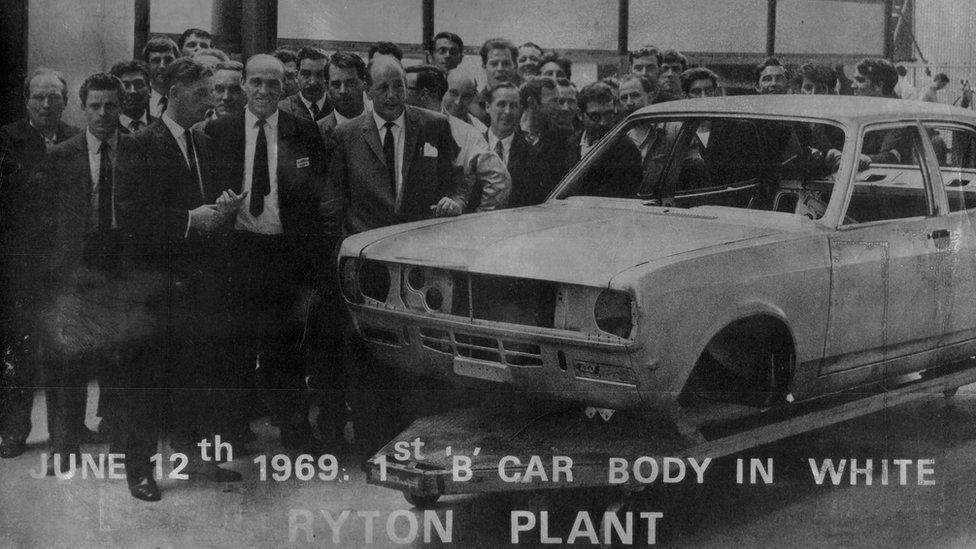

The Hillman Avenger being produced at Ryton in 1969. By this time Coventry had been rebuilt and was a model of brutalist architecture - a little like the car

"When Ryton closed its doors that was the last of the car production in Coventry," Jim O'Boyle said. "And we had fought to keep it open.

"But now we have the opportunity to skill up the workforce and I think it can be done pretty quickly.

"Cov has the ability to bounce back. We have the high-end jobs, we need to look at getting the semi-skilled.

"I can see Coventry doing very well."

- Published27 November 2016

- Published25 November 2016

- Published24 November 2016

- Published1 February 2016