West Country cob houses: The man building a house out of mud

- Published

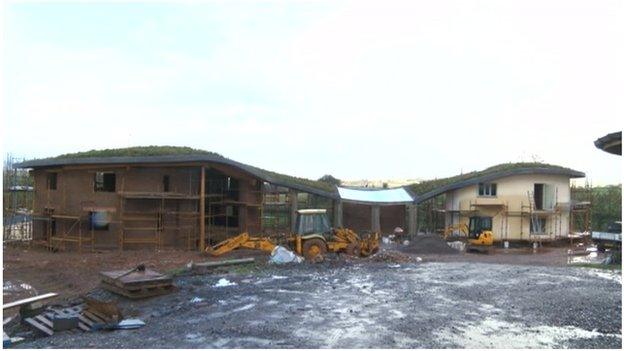

Dingle Dell, which has a main section and an annexe, has turf roofs to increase insulation

Storms and torrential rain have brought devastation to the South West in recent months. Among those counting the cost of the damage have been people who live in or run businesses in buildings made from cob.

A number of walls made from the traditional West Country building material - a mixture of mud and straw - have collapsed during the extreme weather which has hit the region. But despite this, a Devon man is building what is thought to be the biggest cob house in the UK.

Thousands of cob houses and farm buildings survive in the South West, some dating from the 14th Century.

But the extreme weather has led to a number of buildings becoming waterlogged.

A section of wall of the King's Head pub in Cullompton High Street in Devon collapsed on Sunday.

Sections from a nearby derelict laundry fell on to the High Street in January.

And in Wiltshire, the road through Tollard Royal was closed amid fears a cob-built house would collapse.

Mid Devon Council warned that cob buildings needed to be inspected and maintained "especially given the extreme wet weather experienced this winter and the sensitivity of this construction material to moisture".

And yet there has been a very small-scale renaissance in cob building with 10 completed in the last 10 years, said the Devon Earth Building Association.

"Collapses are the combination of the wrong kind of maintenance and the wrong kind of weather," said a spokesman.

"The average age of cob buildings in Devon is probably 300 years, so it is not that vulnerable."

Paddy McNevin, of the South Devon College's Energy Centre, which teaches eco-building techniques said: "Cob has excellent thermal value so why not utilise products and materials that are local?

"It is a very sustainable way of building."

And outside the town of Ottery St Mary in Devon, builder Kevin McCabe is wrestling with mud on his dream home, Dingle Dell.

Kevin McCabe mixes the raw material, earth, sand and straw, on a concrete slab with a digger

Dingle Dell is thought to be the biggest cob-built house in the UK

The house has taken three years to build and will take another year before it will be habitable

Finishing touches are put to a tree sculpture connecting the two parts of the house

The weathering on the exposed wall of a cob house he built next door is a few millimetres over the past five years, which he patches with more mud.

"What's amazing about cob is how resilient it is to the weather," he said.

"You would expect it to dissolve away but actually it is incredibly resilient.

"Cob has its limitations, but if it is used intelligently it is a really wonderful material."

He said the secret was the clay in the local soil.

"Clay is what you put round your pond to keep it dry," he said. "It resists the passage of water."

A cob wall collapsed in Cullompton High Street, sparking warnings from the local authority

Mr McCabe, who has built the house virtually single handed, reckons it has cost about £500,000 so far, not including his labour, with an estimated £250,000 to finish it.

All the raw material has come from the site, a total of about 2,000 tonnes.

Buying it in would have cost about £30 a tonne, so he has saved about £60,000 for raw materials.

"I love the fact that it is from the site," he said.

Cob mix cremation

"It is non-toxic, it is sculptural and most of all it is so beautifully comfortable to live in.

"A lightweight concrete block is three times as strong as this, but it is still strong enough for most situations."

It has also cost him thousands of hours of work - he has been working a 70-hour week in the summer for the last three years on Dingle Dell.

He estimates it will be another year before he can move in with his family.

"There have been times when I have felt pretty daunted at the scale of the project," he said.

"But I have never really wished I had been doing it in another material.

"It is beautiful and so appropriate for this part of the world."

He is finishing a decorative tree made in cob in a glass-fronted passageway connecting the two parts of the house.

"I think that when I die I would like to be cremated and put into a cob mix," he said.

"Then anyone who knows me or wants to remember me can be involved in making a sculpture out of the cob mix.

"I think it's quite appropriate because if it was left outside it would slowly erode back into the soil, by which time anyone who knew me would probably be gone anyway."

- Published24 February 2014

- Published17 February 2014

- Published22 January 2014

- Published20 January 2014

- Published23 August 2010