British Steel: Scunthorpe cuts will leave UK 'exposed', union says

- Published

- comments

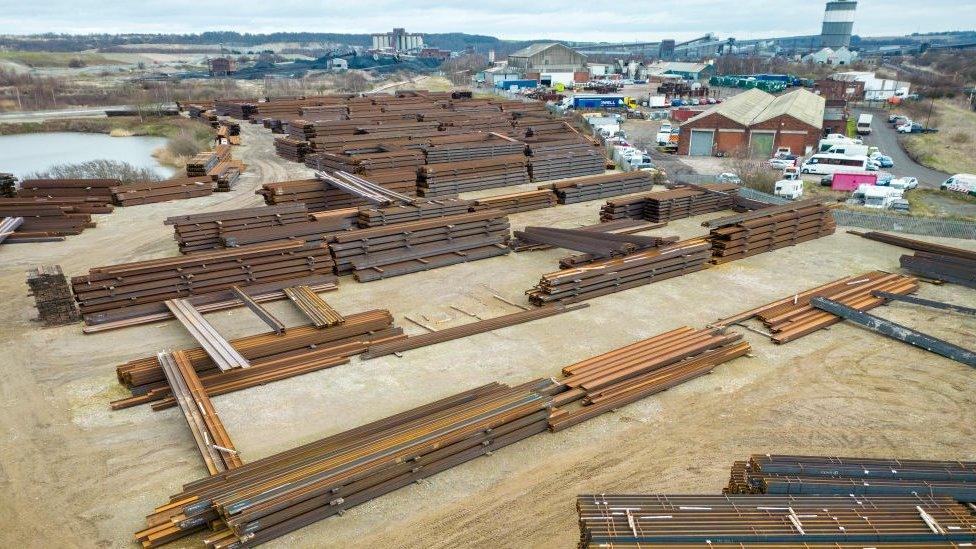

British Steel plans to close its blast furnaces at its Scunthorpe plant

Closing the blast furnaces at Scunthorpe's steelworks would leave the UK "dangerously exposed", unions say.

On Monday, British Steel announced plans to replace the furnaces with two electric arc furnaces (EAFs) - one at Scunthorpe and one at Teesside.

It said the £1.25bn proposal would make British Steel "a clean, green and sustainable business".

However, steelworkers' trade union Community has described the plans as "deeply concerning".

Roy Rickhuss believes the closure will leave the UK "dangerously exposed" to international markets

British Steel, which is owned by China's Jingye Group, said the plans were still "subject to appropriate support" from the UK government, but that the new furnaces could be in operation by late 2025.

Community believes the move could result in between 1,500 and 2,000 job losses, predominantly in Scunthorpe.

Citing Tata Steel's proposal to close blast furnaces at Port Talbot in Wales, the union said the Scunthorpe plans would end the UK's ability to produce "primary steel products", meaning it would instead have to rely on imports.

General secretary Roy Rickhuss said: "We are deeply concerned by British Steel's plans for an EAF-only approach at Scunthorpe and Teesside, and it is vital a meaningful consultation takes place to assess all the options to secure the future of steelmaking.

"The plans that British Steel has announced, combined with Tata Steel's plans, would leave the UK dangerously exposed to international markets."

Blast furnaces use coke to reduce iron ore, whereas electric arc furnaces melt down scrap or recycled steel.

However, Mr Rickhuss said Community believes blast furnaces "continue to be vital in any responsible transition to green steelmaking".

He said: "With the right commitment from all stakeholders we can deliver a just transition [to greener steel] that saves our planet, saves our jobs, and saves our steel."

Community had continually highlighted how an EAF-only approach was the wrong solution to decarbonising the steel industry, Mr Rickhuss said.

He said: "Such an approach would require the import of virgin steel to supplement scrap steel used in furnaces, meaning that carbon emissions would be exported to heavy-polluting countries and the industry would no longer be self-sufficient in the UK. This is dangerous both for the national economy and security."

Trade body UK Steel says electric arc furnaces were ideal for producing products such as girders

Gareth Stace, director general of UK Steel, which represents the sector, said both British Steel and Tata Steel were responding to demands for greener steel from "government, society and the market".

Describing EAFs as "tried and tested", Mr Stace said it made sense for the UK to use its "abundance" of scrap steel.

"We collect between 10 and 11 million tonnes a year yet we export 80% of it to countries such as Turkey, Bangladesh and Pakistan," he said. "So why wouldn't you want to use electric arc furnaces? You would need massive investment to keep the blast furnaces open."

Mr Stace said "almost all" steel products could be made using EAFs, although they were most commonly used in the UK to produce "long, thin" products such as girders for the construction industry.

Meanwhile, Councillor Rob Waltham, leader of North Lincolnshire Council, said he believed blast furnaces "should be kept for as long as possible".

However, he said the "business context" could not be ignored, adding British Steel's customers now demanded "greener steel", made using EAFs.

The BBC has approached British Steel for comment.

Follow BBC East Yorkshire and Lincolnshire on Facebook, external, X (formerly Twitter), external, and Instagram, external. Send your story ideas to yorkslincs.news@bbc.co.uk, external

- Published6 November 2023

- Published4 February 2023

- Published8 June 2023

- Published3 November 2023

- Published28 June 2023