Bath scientists develop 3D-printed artificial knee

- Published

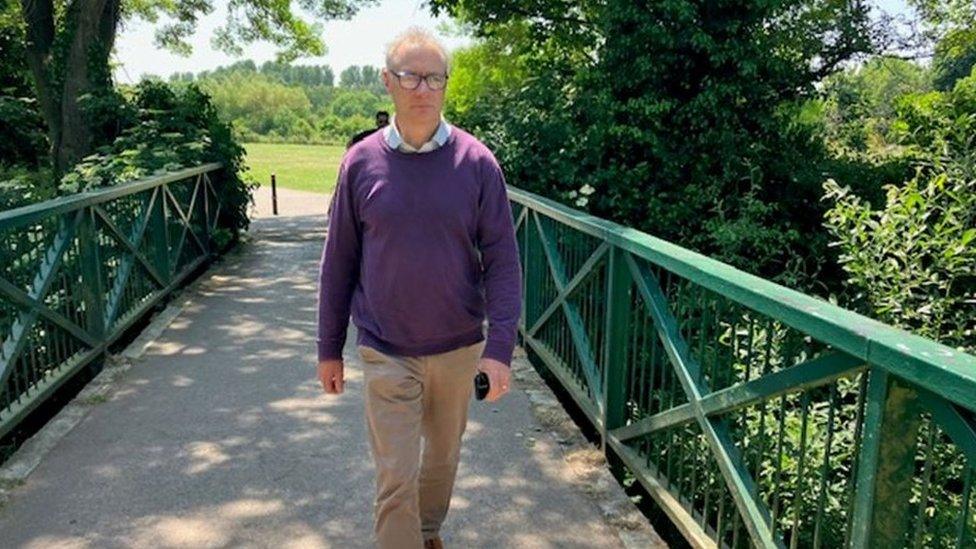

David Tarbet was one of the first five patients in the country to have a new type of knee operation

Scientists have developed a 3D-printed implant to help patients suffering osteoarthritis in their knee.

The tailored osteotomy for knee alignment treatment is designed to preserve the person's existing knee joint.

Developed by University of Bath scientists, the technique is designed to make operations quicker and safer.

One of the first to have the treatment, 55-year-old David Tarbet, said the surgery was "remarkable".

Taking part in a safety trial to fit the high-tibial osteotomy (HTO) plates, Mr Tarbet, from Dartmoor, said: "Although it was quite sore for a couple of months I was able to get on an indoor bike quite quickly."

The 3D HTO plates are used to realign a patient's knee, making them more stable, comfortable and better able to bear weight than existing generic plates.

Mr Tarbet said that within six months he was able to complete a competitive bike ride, "which was fantastic."

How does it work?

To plan how much correction a patient needs, doctors take an X-ray and a CT scan of their shin bone.

A surgical guide stabilisation plate is then generated by using the 3D printer.

This is then temporarily fitted to the patient's tibia, one of two bones that comprise the leg, using pins.

Those pins are then released and two screws are inserted, creating a wedge in the bone to correct its alignment.

The stabilising plate is then put on top, allowing the digital creation to become a surgical reality.

HTO plates have already been safety-tested virtually, in a computer-based trial using CT scan data from 28 patients. It has led to approval from the Medicines and Healthcare products Regulatory Agency.

"This computer-modelled trial, the first in the world to demonstrate the safety of an orthopaedic device, modelled the stresses that would be exerted on the bespoke plates. and showed they were comparable in safety to the standard treatment."

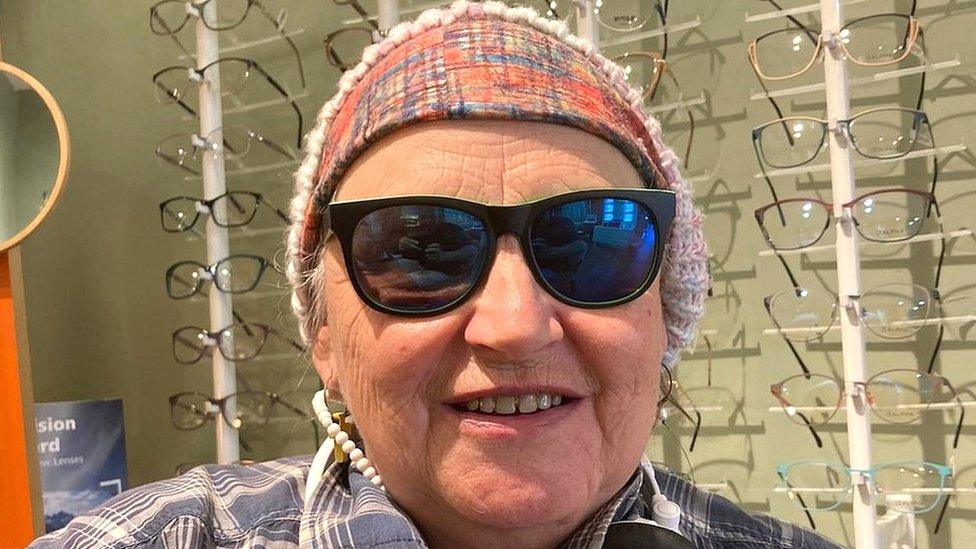

Professor Andrew Toms believes the new technique will help younger patients who do not need a full knee replacement

Working with the university to develop the product Prof Andrew Toms, director of orthopaedics at the Royal Devon and Exeter Hospital, said that for patients between the ages of 40 and 60, having a total knee replacement is not an easy option as it won't last long enough.

He said: "A knee has three 'car tyres' - an inner, an outer and a kneecap. A traditional total knee replacement replaces all of those in one go and that's normally what you would do with your car.

"When they are worn out what we tend to do is to balance the knee out in those younger patients by re-aligning the knee, by taking the pressure off the worn car tyres and straightening the limb out.

"That's what this osteotomy, this technique is all about."

'Make it widely available'

Prof Richie Gill, who developed the product at the Centre for Therapeutic Innovation at Bath University, said: "The big difference is there isn't that guesswork which is happening at the time of surgery.

"I think more surgeons are interested in doing this type of joint-preserving surgery.

"You can do it at a sooner point in the disease progression than you can with a knee replacement, so we are hoping to make it more widely available."

After an initial safety trial with the five patients, 50 others are now being recruited across south and west England, Cardiff and Oxford, to take part in a trial comparing traditional knee replacement with this technique.

Follow BBC West on Facebook, external, Twitter, external and Instagram, external. Send your story ideas to: bristol@bbc.co.uk

- Published12 June 2023

- Published31 May 2023

- Published16 February 2016