Mossmorran flaring: £140m to be spent fixing Fife plant

- Published

ExxonMobil plant manager Jacob McAlister said he hoped residents would notice a difference within a year as a result of the new investment

A total of £140m is to be spent reducing flaring and improving the reliability of a Fife chemical plant.

ExxonMobil said it had started recruiting 850 temporary workers to carry out the work over the next 12 months.

The operator said the investment was on top of the £20m it spends annually on maintaining its Mossmorran site.

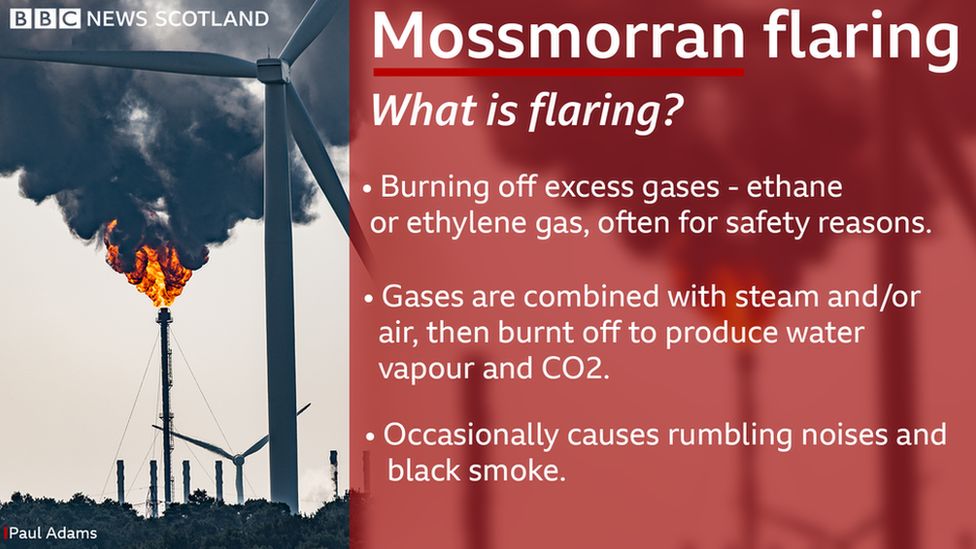

Residents have complained of light pollution and noise often disrupting their sleep during flaring events.

ExxonMobil said the work - which includes fitting flaring tips and other technology to reduce flaring - would be completed by September 2020.

Currently, the plant has temporarily shut down while two of its three boilers have parts renewed and repaired.

The company said it expected to resume operations producing ethylene during the fourth quarter of the year - between October and December - after the shutdown which began on 12 August.

Exxonmobil's ethylene plant at Mossmorran is temporarily shut down

The work will involve building a flare at ground level which means they will use the elevated flare less often, reducing the visual impact of the plant. The multi-million pound ground flare will be built by 2024.

In addition, the work will lead to a reduction in the amount of vibration felt by local residents, plant bosses claim.

Plant manager Jacob McAlister said: "The reliability of the plant has not been where we want it to be and we recognise that - £140m is a major step and shows our commitment that we are addressing these issues.

"We built this [elevated flare tower] 34 years ago to keep the community safe and it is doing its job but we have more advanced technology now that we didn't have when it was built which we hope will address the issues we have been having."

'Bated breath'

He added: "We're intent on making improvements, which will drastically reduce flaring and the duration of elevated flaring. I hope in one year from now a significant portion of this project will be in place and that the number of flaring events will be driven down.

"We are not spending this money to pacify the community, we are concerned about how the plant is impacting on their lives and we are announcing how we are addressing that."

James Glen, chairman of the Mossmorran Action Group, said residents believed there had been "major under investment" in the safety and maintenance of the plant.

He added: "It would be good to know how much of the £140m planned expenditure is just to bring the plant up to a reasonable safety standard.

"We have been promised flaring tips before and these never reduced the levels of flaring and the noise impacts.

"So the communities will wait with bated breath to see if this is an improvement."

Residents have complained of light pollution and noise during flaring

Environmental watchdog Sepa said it had been pressing for ground flaring to be introduced at the site - but wanted it introduced sooner than 2024.

Sepa chief compliance officer Ian Buchanan said: "We look forward to working with ExxonMobil on detailed proposals to both address the root causes of flaring and also on the requirement we have set around the 'shortest period possible to plan, design, build and safely integrate' new ground flare technology which will significantly reduce impacts of flaring on local communities."

Lesley Laird, MP for Kirkcaldy and Cowdenbeath, said the major investment justified the concerns communities had expressed for years.

"Residents were patronised for the most part, and those who dared raised concerns publicly were derided for scaremongering," she added.

"It is only through the concerted pressure of the Mossmorran Working Group that Sepa, HSE and the companies have finally all had to face up to the reality that communities had reached their absolute limit, and that they would have to act as the plant was clearly not fit for purpose.

"More detailed responses are now required from all of these organisations as to how, under the watchful eye of Sepa and HSE, Fife Ethylene Plant was allowed to deteriorate to this extent."

Energy Minister Paul Wheelhouse, said: "Given community concerns, the Scottish government has been clear that the frequency of unplanned flaring at the site is unacceptable and that the operators must take steps to address this, so this announcement of action being taken is therefore to be welcomed."

Ian Buchanan, a chief officer at Sepa, said: "Sepa has been clear that repeated unplanned flaring by ExxonMobil was both unacceptable and preventable and that in future flaring will be the exception rather than routine.

"Having served a series of notices and operating permit variations to drive investment, including in noise reducing flare tips by 2020, we welcome today's broad announcement from ExxonMobil."

Alan Mitchell, chief executive of Fife Chamber of Commerce, said: "First and foremost, this is tremendous news for the workforce at Mossmorran.

"But the benefits will be felt well beyond the plant's boundaries.

"It will create jobs in Fife and opportunities for contracts and work for local companies."

Meanwhile, BBC Scotland has learned the plant has been issued with an improvement notice over the risk of an explosion.

The Health and Safety Executive (HSE) said ExxonMobil had failed to take all measures necessary to reduce the risk of "firebox explosion from furnaces".

The firebox is an area in the plant's furnaces where fuel is burnt.

'Managing safety risks'

Inspectors said the risk came from an uncontrolled accumulation of unburnt fuel in the firebox.

The HSE notice, which affects seven furnaces at the plant, states "the measures currently in place are not sufficient to reduce the risk to as low as reasonably practicable".

It was issued in July and ExxonMobil has until March next year to comply with the improvement order.

On the HSE notice, Mr McAlister said: "Our safety performance is such that in the 30-plus years we've been in operation we've never had a major safety incident.

"We've gone over 25 years without a lost time injury on the site. You don't do that if you're not managing the safety risks appropriately. We are managing the safety risks, that's our number one job to ensure that we do that right."

In August it emerged that Scotland's environmental regulator Sepa had received almost 1,400 complaints about the Mossmorran site, which is also shared by Shell Fife NGL.

Both companies had their permits modified and were told to install flare tips that reduce noise.

- Published6 September 2019

- Published2 September 2019

- Published30 August 2019

- Published24 August 2019

- Published23 August 2019

- Published22 August 2019

- Published13 August 2019

- Published10 August 2019

- Published30 June 2019

- Published14 June 2019

- Published27 April 2019

- Published23 April 2019

- Published25 April 2019