Coronavirus: Welsh businesses 'essential' to PPE supply

- Published

Welsh firms meet the challenge of producing PPE in case of a second wave

A "can-do" attitude among businesses in Wales has made them an "essential" part of the PPE supply chain during the pandemic, it has been claimed.

The director of a manufacturing firm which started making PPE in March said firms in Wales had been motivated to create a "sustainable" supply chain.

The head of procurement for NHS Wales said businesses will be needed in the event of a second wave.

In April, PPE supplies in Wales were down to enough for "just a few days".

The admission came from the Welsh Government at the height of the pandemic as international competition for PPE meant delays in supply.

Across the UK there were also issues with the quality of stock provided from abroad.

PPE products made in Wales are of a higher quality, according to Mark Roscrow, head of procurement for the NHS Wales Shared Services Partnership

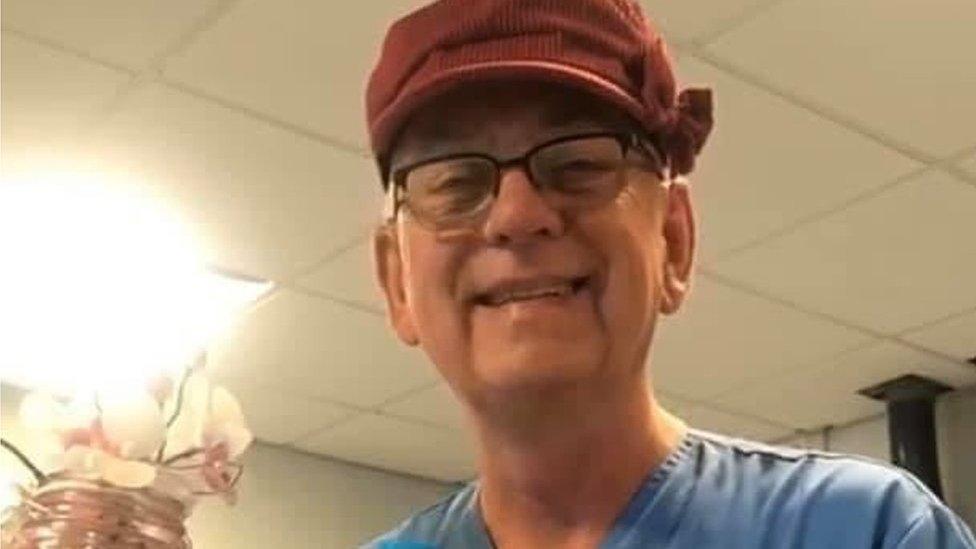

Mark Roscrow, head of procurement for the NHS Wales Shared Services Partnership, said having Welsh businesses involved in production had provided "a greater sense of assurance".

"We don't have to stock as much as we normally would have done because we have a product we can rely on on our doorstep" he said.

He estimated there was now five times the level of PPE stock held by NHS Wales when compared with the start of the pandemic.

Welsh Government figures show stocks stood at almost 130 million items at the end of July, and last week it announced hundreds of millions of pounds of extra funding to boost levels further.

Part of that supply will come from businesses who had never made PPE until the coronavirus outbreak.

British Rototherm, based in Neath Port Talbot, manufactured industrial measuring instruments until mid-March when they got a call from Cardiff and Vale University Health Board, which urgently needed face shields.

British Rototherm has gone from making 1,000 to more than 50,000 face shields a day, its managing director Oliver Conger says

The company's managing director, Oliver Conger, said they quickly figured out how to make the face shields and delivered on the order. It soon became clear how much need there was.

"Within a couple of days the phone was off the hook," Mr Conger recalled.

"We started producing about 1,000 a day, then we upped that to 10,000 a day, and right now we are producing in excess of 50,000 face shields a day."

The company also moved into making face masks, and in July it was announced they would be benefitting from part of £14m in UK government funding aimed at boosting supply of high-quality face masks.

The "can-do" attitude of Welsh business had helped establish a PPE supply chain, Mr Conger believes

Mr Conger said he was sure the location of the business was a big part of its success.

"The spirit certainly within Wales has been a can-do attitude - let's get this done, let's make it a success [and] let's have a sustainable manufacturing base for PPE."

To get its products up to the required safety standards, British Rototherm enlisted the help of the Surgical Materials Testing Laboratory in Bridgend.

It is the only NHS facility in the whole of the UK able to test the full range of PPE for adherence to health and safety guidelines.

The production line at Rototherm

Laboratory director Pete Phillips said he believes local PPE supply is the best way to ensure quality.

"It's impossible for us to go out to audit a manufacturer in China," he explained.

"You have to rely on agents on the ground in China, but if it's a manufacturer of masks in Pontardawe, someone can actually go down and look at their quality management system and look at the products."

At the height of the outbreak, Mr Phillips said PPE stocks were low so the health service had to rely on less well-known or untested suppliers, which did lead to issues with quality.

The laboratory found more than 60 faulty or fraudulently certified batches of PPE in the first four months of the pandemic, which Mr Phillips said was more than it had seen in the past 10 years.

Asked whether the UK could ever supply all of its own PPE, Mr Phillips said it was "certainly doable", adding the country now has the same capacity for keeping prices low as the world's major manufacturers.

"In the past, people went to China because of cheap labour, but now China is moving towards a lot of automation and we can do automation here in Wales," he added.

While being self-sufficient in terms of PPE is the aim, Mr Roscrow believes that is still "some way off".

For now, his priority is having the stock ready for the demands of the next few months, and a potential spike in cases.

"We're taking this point in time to re-stock product to a higher level than we would have at the start of this [pandemic]. That link to Welsh-based suppliers makes it easier."

Mr Roscrow said he knows PPE is just one part of the plan to fight Covid-19, which includes an international effort to find a vaccine.

He added: "Hopefully a combination of these things will put us in a far better position to respond to a second wave."

- Published3 June 2020

- Published1 June 2020

- Published1 May 2020

- Published14 April 2020

- Published14 April 2020

- Published11 April 2020

- Published30 March 2020