Toyota invests £7m for new hybrid engine at Deeside plant

- Published

Toyota's Deeside factory opened in 1992, producing one engine model

A new hybrid engine is to be built at Toyota's Deeside factory, securing hundreds of jobs.

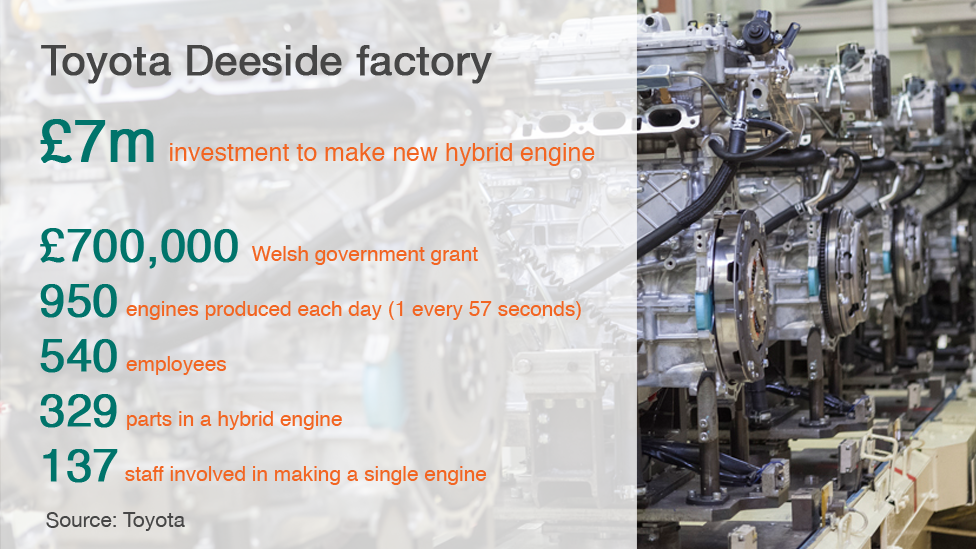

More than £7m will be invested in production facilities at the engine plant with a £700,000 grant from the Welsh government.

The 1.8 litre engines will be exported to Turkey to be built into a model based on Toyota's C-HR concept car, external.

There are currently about 540 employees at the Deeside factory, making 950 engines a day in 13 variants.

The new hybrid engine will be built alongside current petrol and hybrid petrol engines for the Auris model, which go to the company's factory at Burnaston, Derbyshire where the vehicle is produced.

Engine plant director Jim Crosbie said: "This announcement is a big vote of confidence in the high skills, quality and commitment of our workforce."

In 2015, Toyota became the world's top-selling carmaker for the fourth straight year, selling 10.15 million cars overall with 209,000 hybrid vehicles in Europe, up 17% on 2014.

Engines and components made at Deeside are exported across Europe, South America, South Africa and Japan.

Edwina Hart, Minister for Economy, Science and Transport, said: "I am delighted this very significant investment has been secured for Toyota's facility on Deeside.

"It will not only provide a platform for growth in what is an extremely competitive market but will help secure the long term sustainable future of the plant and safeguard skilled, well-paid jobs in the region."

Minister Edwina Hart tours Toyota's Deeside plant on Thursday

Analysis by Sarah Dickins, BBC Wales economics correspondent

The Toyota new engine line is the latest example of a Welsh plant winning investment because of the success of its existing set up.

It's good news for Toyota's workers on Deeside and good for the Welsh economy. With 540 employees spending their wages in the local economy and the value of the engines made a year, Toyota Deeside helps the Welsh economy and helps to lift statistics like GVA - the value of goods and services.

It's not just Toyota on Deeside that is feeling confident. While some parts of the economy are anxious about global slowdown and what the year will bring, automotive companies in Wales are busy on the whole.

Cars are not assembled in Wales but important parts are and companies like Magor Designs in Resolven design the machines to make parts that others assemble and then go to the carmakers. It's a complicated supply chain which, overall, injects £3.3bn into the Welsh economy.

The secret to success in this industry is to be ahead of the game - adapting quickly to make parts for the next generation of vehicles which tend to be cleaner and more efficient.

18,000 people work making car parts in Wales. Together they are paid around £500m a year. At each stage in a new vehicle's design the supply companies have to compete against other suppliers - sometimes in their own companies - across the UK and Europe.

Toyota Deeside does not buy parts from Welsh suppliers but it does buy services from other companies.

But all the way from the Toyotas and Fords to small parts makers, the way to succeed is the same; they have to continually improve what they do and adapt to demands from the car makers.

- Published27 January 2016

- Published5 November 2015

- Published3 May 2011