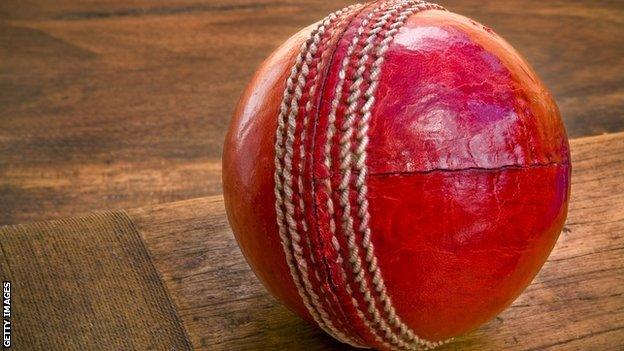

County Championship: Why are so many of this season's balls going out of shape?

- Published

New Zealand captain Kane Williamson successfully got the Dukes ball changed early during England's second innings of the first Test at Lord's after it went out of shape

Cricket balls are hardy items, expected to stand up to the toil of being bowled down a pitch, thrashed by willow bats, rubbed, scuffed and made wet as they are tossed about the field.

Yet in 2022, in the County Championship, something has changed with the classic Dukes ball. They are losing their shape, rapidly.

During Durham's recent match in Chester-le-Street there were 11 unscheduled ball changes during a four-day game with Glamorgan, including five in one day.

In a first-class match, the fielding side starts each innings with a new ball which is meant to be used for 80 overs before being replaced.

Umpires and players say they have not come across such an issue for a long time with the brand.

It's not just happened to Durham either, it's been happening across the county game.

And, clubs have been struggling to get hold of replacements. There has been a meeting with the England and Wales Cricket Board to try to get to the bottom of the matter.

It has been claimed the seams around the balls have been altered this year and that has led to them weakening.

However, Dilip Jajodia, the businessman who owns British Cricket Balls Limited - the firm which manufactures Dukes balls - says this is not the case.

"We were not aware of any issues until events started to happen during play," he told BBC Radio Newcastle.

"We only become aware when clubs start to report back to us and then we have to investigate what may have caused the situation. That could be one of many things.

"We have a tracing system. Every ball has a number on it and we can go back and see when it was made and which batch of materials was used. We were asked by the ECB to make balls lighter in colour.

"I don't know if that means different chemicals are now being used which are having an effect on the leather. We need to speak to the tanneries about this. They are small companies and are still recovering from the effects of Covid."

Umpires James Middlebrook (left) and Alex Wharf (right) check the ball during Durham's County Championship game against Glamorgan in May

The ECB has told BBC Sport it is aware of the problems and is working with Dukes and the first-class counties "to ensure the best quality balls are used" for the remainder of the championship season.

Unlike footballs, rugby balls and golf balls, where mechanised processes cut down on the time taken to produce items in large quantities, the method of creating a cricket ball remains a traditional one.

Rather than synthetic materials like polyurethane or artificial leather which tend to be used in other sports' equipment, cricket balls are still produced from cork, wound in string and then cased tightly in leather with the classic seam.

"We will look into what is happening but these things take time," Jajodia added. "It actually takes nine months from cow to cricket ball. It is a slow process. So if there are issues it also takes months for them to appear.

"The actual manufacturing process is done by hand and takes three and a half hours per ball.

"We could make balls which last 80 overs but that would not be good for the game. They would be like rocks. Nobody wants that. But bats are enormous these days. Much bigger than before. Pitches are harder too and balls go through so much more pressure than they used to. That could be a factor."

'If it is a technical issue then we will find it'

With discounts given to clubs, each ball costs around £50 plus VAT. However, actually getting hold of replacements has been an issue, with clubs recently being restricted to 12 at a time.

Jajodia says the industry is still recovering from the effects of the pandemic, which in turn led to shortages in supply and a lack of balls being stored in warehouses where they can mature.

He added: "We are still being affected by Covid which also impacts the supply lines because we need cork, leather, rubber, linen and thread.

"You need 10 years' experience to make a cricket ball. It is a challenge for all involved.

"Demand has gone up now everybody is playing again but we don't have enough balls to go around so maybe that is an issue. If you can store them for a period and let them settle down and mature, then that is preferable.

"Unfortunately, we have had to resort to a 'just in time' delivery method and that does not help."

The standardised process of producing cricket balls has remained unchanged for nearly 30 years

Factors within the unique process could well be the cause of the issues, and already Jajodia and his company are considering the knock-on effect for next season.

"We are using exactly the same standard to make the balls. That has not changed since 1994," he added. "The threads are the same and the seams should be the same. Maybe the dye is one reason?

"We need to look into it to make sure the balls for 2023 are perfect. If it is a technical issue then we will find it.

"We always use Angus hide because it is the best but there are always imponderables. We dip the hides in vats of dye. They are then greased to keep the water out. Some stay a lighter colour, depending on the cow, others are a darker red and some are almost black.

"If just a few balls go out of shape then it may be down to one cow hide. If it is more then may be that is down to a bad batch of hides. Equally we have had used balls returned to us which we have been told had gone out of shape and they still passed through the measurement ring.

"Yes, there has been an issue this year. But I also think there has been some group thinking which has led to a bit of hysteria. But we are talking to people and when the dust settles we will get the matter sorted out."