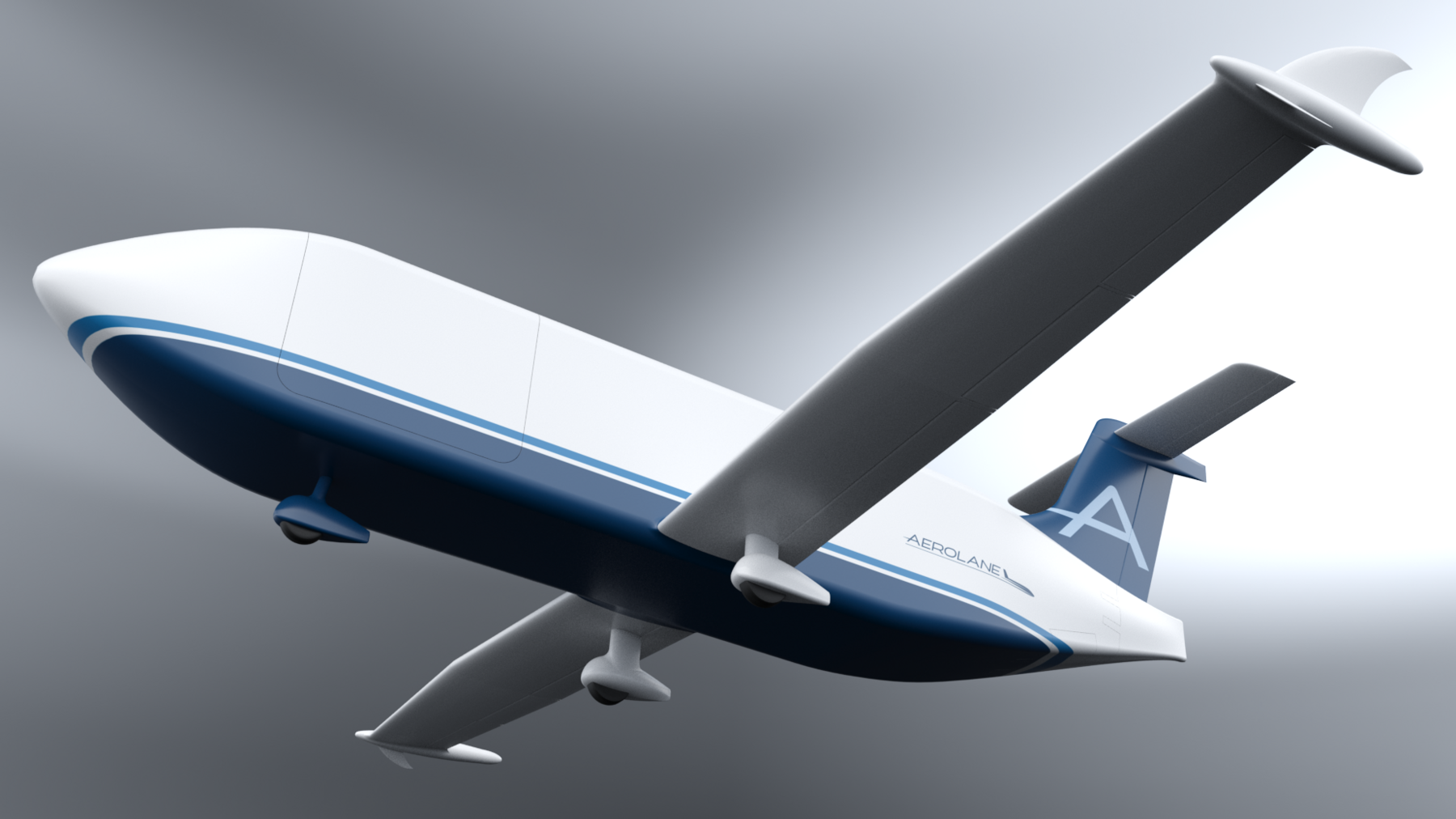

Could the 'flying piano' help transform air cargo?

Dubbed the "flying piano", Aerolane's test aircraft is surfing air currents

- Published

US start-up Aerolane is seeking the secret to airborne surfing.

Geese already know how to do it. When you see them flying in a v-formation, they are surfing on the air currents created by formation members ahead and around them.

At an airfield in Texas, Todd Graetz is hoping to use that concept to disrupt the market for air cargo.

Aerolane has been mimicking the tricks used by migrating birds, aided by modified planes towed into the air by another aircraft.

Smoke released from the leading plane allowed cameras installed in the towed aircraft to capture vortices in the air that a glider can exploit to stay aloft.

Their latest test aircraft is known as the “flying piano” because of its poor gliding characteristics.

Its twin engines idle for electrical power while it glides along with propellers turning for purely aerodynamic purposes.

Other tests have measured the tension in the towing line.

They spotted when the line went slack, indicating the glider is surfing along on currents generated by the aircraft ahead.

Aerolane's plan is to feed all this data into a program that will guide an unmanned cargo plane through wakes and turbulence to exploit the possibilities of gliding long distances without burning fuel.

One or more such cargo planes could be towed by a jet, also carrying cargo, to their destination where they would land autonomously.

The only fuel costs would come from supplying the towing aircraft’s engines.

In theory this should work like a truck pulling a trailer, with air currents doing much of the heavy lifting. This is what Mr Graetz calls “a combination of gliding and surfing”.

The same idea occurred to Airbus, which tested the technique in 2021 with two A350 airliners flying 3km (1.9 miles) apart across the Atlantic.

Although the aircraft were not connected by a tow line, the experiment saw one aircraft winning an uplift from the lead A350’s wake to reduce CO2 emissions and fuel burn.

Airbus has experimented with flying a jet in the wake of another to conserve fuel

Mr Graetz, a pilot with 12 years’ experience, founded Aerolane with Gur Kimchi and Doron Appelboim, veterans of Amazon’s drone delivery project, on the basis that “there has got to be a better way to get more out of existing aircraft".

The project has raised eyebrows among experienced pilots. Flying large gliders in commercial airspace means meeting strict flight safety regulations.

For instance, the towing aircraft has to be confident it can release the tow line at any point in the flight, safe in the knowledge that the auto-piloted glider can make it down to a runway without dropping on top of the local population.

Aerolane says a small electric motor driving a propeller will act as a safety net on their cargo gliders, giving them enough juice to go around again if a landing looks wrong or to divert to another location close by.

Aerolane hopes that a glider something like this might one day carry air freight

Mr Graetz counters that Aerolane employs active commercial pilots who are hard-headed about the practicalities of the project.

“We’ve engaged outside advisors to be devil’s advocates," he adds.

He says big freight businesses are interested in anything that allows them to cut the cost per delivery.

On top of the cost of fuel, air freight firms also have to think about jet engine emissions and a shortage of pilots.

James Earl, a former RAF helicopter pilot and aviation consultant, thinks Mr Graetz may just be onto something.

“It stands to reason that gains can be had by slipstreaming and combining efforts in the sky. And any innovation in the cargo space is good.”

However, he cautions that public acceptance of unpowered cargo flights over built-up areas is another thing entirely.

“It should have a good gliding range to get to a landing spot in the event of a major failure by the tow plane. Whether that can be effectively communicated to the public is another matter though.”

Fred Lopez was initially sceptical about Aerolane's prospects

Regulators are likely to be cautious as well, particularly in the US, where the Federal Aviation Authority is under pressure after serious problems with Boeing aircraft.

Mr Graetz replies that his team has complied with every request from the FAA so far. “The FAA has always been super risk averse. That’s their business!”

Fred Lopez spent 36 years in aviation operations at cargo giant UPS. As he says, he’s put “my entire adult life” into working out the most cost-effective way to operate an air freight business.

Mr Lopez admits he was profoundly sceptical about cargo gliders when Aerolane first approached him. But the prospect of serious fuel savings won him over and now he sits on their advisory board.

Cutting fuel costs is an obsession in civil aviation. When the upturned wing-tips we see out of a cabin window became a standard design feature airlines cut fuel costs by around 5%.

But gliders only consume the fuel required by their tow plane. If that too is a cargo aircraft, a pair of gliders drawn by one jet represents a significant reduction in fuel consumption on a large shipment.

The initial Aerolane design uses their autopilot plus what Mr Lopez terms a human “safety pilot”. This should make certification from the FAA easier.

“Aerolane is not trying to change everything at one go” he says.

Their ultimate goal is autonomous operation using AI, or as Mr Lopez puts it “to pull the pilot out of the seat".

And, if the flying piano can surf, then who knows what's possible?

More Technology of Business

- Published2 July 2024

- Published25 June 2024

- Published14 June 2024